In 1991, the first production modular Ford engine was the 2-valve SOHC V8. This engine was first found in the Ford development phase shop in the Lincoln Town Car platform. Commonly referred to as the ‘mod motor’ by Blue Oval enthusiasts, the first version of this modular Ford engine referenced above, only produced a measly 190 hp and 270 lb-ft of torque. Which frankly, didn’t capture any world renowned attention for quite a few years. Fast forward to present day, and the potential of this remarkable engine platform has made itself known thanks to multiple tuning shops who specialize in building mod motors.

One man has dedicated 20-plus years of his life to expanding on what Ford started after introducing this overhead cam V8, and that’s John Mihovetz; owner and operator of Accufab Racing. His 2008 Pro Mod Mustang holds the world record for being the quickest and fastest Modular motor ever, with an outstanding 5.88 E.T. at over 250 mph.

During the last 20 years, Mihovetz has been the man behind a majority of every single modular record in the 1/4-mile. Being the first in the 8-,7-,6-, and 5-second zones with a modular engine. His portfolio of achievements with this engine platform is quite a lengthy one, which alone makes him the ‘mod motor authority.’ Mihovetz is the ideal candidate to rifle through the common misconceptions that surround this highly potent engine platform.

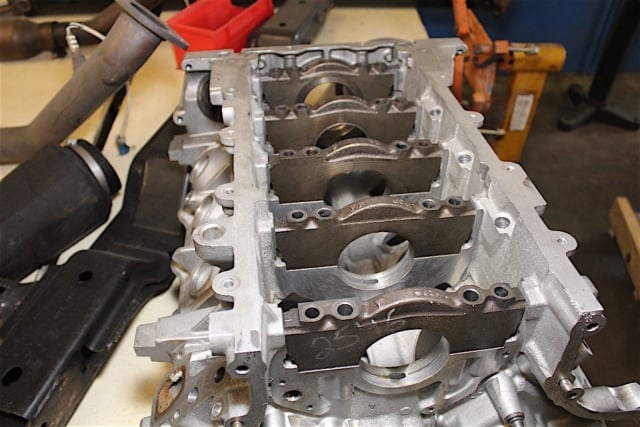

The Building Blocks

When it comes to modular engines, it’s not the iron block that reigns supreme in regards to making significant power. The aluminum factory ‘Teksid’ 4.6 and ‘Cobra Jet’ 5.4 blocks are the pinnacles of horsepower potential. This potential is completely head-to-head in terms of performance, with both factory blocks providing exponential promise in the 1/8-mile to standing-mile competition. Instead of following the thought process that one engine is better than the other, we asked about the misconceptions of comparing the two powerplants.

While iron is a more durable metal in comparison to aluminum, both the modular 5.4 and 4.6 blocks lack material in the certain areas and this results in a weaker block design.

“That’s a general misconception,” Mihovetz said in regards to iron blocks being stronger than aluminum ones. “Ideally, it depends on strength, and what you’re doing. Certainly, the iron block is a pretty decent piece up to a point, and if you’re below that point it works fine. If strength is required beyond, by far the Teksid block is the best piece — specifically the 4.6 4-valve engines.”

Mihovetz continued his thoughts on the comparison. “It’s the same issue with the 5.4 block. The biggest negative thing about the iron block is that the cylinders are too thin on an untouched block. If you sonic-check the thickness, you would find that it’s between .120- to .125-inch, so it’s just too thin,” He said. “And, of course, everyone thinks bigger is better, so they bore it .030 over and thin the cylinder wall out even more.”

The cylinder liners of this iron modular are just not up to the task of making the power that is needed to run into the 5-second range.

“With that being said, as soon as you make decent power the block ends up splitting. Where the aluminum block has an advantage, specifically, is in the case of the cylinder liner,” Mihovetz explained. “A typical sleeve is 90-thousandths thick in its stock form, and then you have anywhere from a 1/4- to 3/8-inch added wall thickness of aluminum to back it up. This added material helps keep the cylinders round.”

According to Mihovetz, as cylinder pressure builds in both the 5.4 and 4.6 iron blocks, the issue of cylinder sleeves only being supported top and bottom becomes a consideration. This shortfall reduces the potential of the block and does not allow for a reliable base to make a massive amount of power.

Mihovetz has utilized a 99 Teksid Cobra block (which is the most resilient form of 4.6 mod motor engine blocks due to it’s improved main webbing) to make a majority of his record-breaking passes in the 1/4-mile, including his famed five-second barrier-breaking passes.

Heading In The Right Direction

The three cylinder heads that help put Ford SVT program on the map. The 03-04 Cobra head (left) that helped put fear into every LS owner. The B head (middle) stands front and center, a DOHC cylinder head that is more responsible for crushing records than any other. Lastly, the Ford GT Supercar head (right) is the fastest of the bunch, holding records in both the 1/4 mile, standing mile, and 1/2-mile.

With all this hustle and bustle about DOHC cylinder heads, it seems the common consensus is that the newest Ford modular heads on the market are the pinnacle of modular performance. Most would be surprised to know that this belief is not exactly the case, and is most certainly a common misconception among the community. While the fastest and quickest Mod motor-powered car in the world is utilizing a set of Ford GT supercar heads, this wasn’t the head that broke a multitude of records since Ford birthed this revolutionary engine family.

Despite the awkward port design of the B head, which is due to the IMCR’s that helped lower end torque by shortening runner length, with a port job this head can flow comparable numbers, and possibly outflow, a ported set of GT Supercar heads.

“You know you have to start in a particular order, and it depends on what the end goal is and what window are you playing in,” Mihovetz entailed. “For example, the C head is probably the best cylinder head for up to 7,000 rpm. Average power for road racing that can rev that high is a pretty hard thing to beat; but anything past 7,000 rpm, you’re a dead duck.”

Mihovetz continued, “When we broke the 8-,7-, and 6-second barriers, all we had was the B heads (which come factory on Lincoln Mark VIII’s and ’96-98 Cobra’s). For some reason, there is a world full of people who think everything else is better than the B heads, but those heads were in the car when we broke all the records.”

“The B, Navigator, and C heads all have the same exhaust port. The ‘03-’04 Cobra head has a little bit of a different variant of the same port, but it doesn’t flow any better; it’s essentially just a bigger port. The B head has the largest runner volume of all the heads, so that’s what makes it work at 10,000 rpm,” Mihovetz said. “The same things that make it work also make it not have the power low down, due to a design that results in reduced port velocity. The 4.6-liter in a 281 cubic-inch version and those same heads on a 5.4-liter would be pretty good because it would have so much more cylinder fill.”

Mihovetz told us the best heads are the Ford GT supercar heads. Right behind them (realistically, even parallel, and in some instances even better), are the B heads.

“Nobody talks about them, and everyone seems to hate them. Nobody appears to know how to work on them, and nobody knows how to make them work,” Mihovetz lamented. “The B heads have tremendous potential. The only drawback is the thinner castings when compared to the GT head, which is infinitely durable in comparison.”

Perfecting a combination requires a bit of sacrifice, here is one of the spent cylinder heads that was repurposed to give insight into the inner workings of a GT head.

Mihovetz told us when his Cougar was running 6.30s, he decided to make the jump over to the GT heads and ran almost identical numbers. “The difference is people can afford B heads, and you can find them because they are a dime a dozen. GT heads, on the other hand, will run you upwards of $3,000. What I’ve found is that for the long haul, the GT heads are a better head and will live longer than the B heads. The heads that are on my racecar have been on there for about four, or maybe five years. A set of B heads at that power level lasts between 1 to 1-1/2 years,” he said.

A Look Under The Covers

One of the biggest misconceptions surrounding the modular motor is that the factory components aren’t up to weathering the stress required to make significant power. From the outside looking in, it may seem that all of the valvetrain components wouldn’t be able to hold up to upwards of 10,000 rpm and the fury of over 60 pounds of boost, but most of these key elements are retained in the world’s fastest Modulars.

“I haven’t seen anything that beats the stock stuff,” Mihovetz explained. “On the primary chains, all you really need is an OEM Ford chain set; nobody makes a better chain than that, and arguably they work pretty good. There are things that you can do to them, such as have them rem-coated and cryogenically treated. There’re a few things you can do to improve the service life. But, at least at the level that we’re racing, it’s a maintenance item for us. We go 50 runs, and they come out.”

Unknown to the majority of the modular community, the primary chains of the SOHC and DOHC engines differ slightly. One of which is the polishing of the outer chain of the Cobra timing chains; this decreases the amount of wear that the plastic timing guide will see during operation.

Another key component to back up these claims are the Ford GT followers (rockers). Just like the primary timing chains, there are aftermarket options that were constructed to add durability and improve on the factory stamped steel design. While these options may have an added roller valve-side tip, these pieces add weight to the valvetrain and haven’t shown any vast improvements in Mihovetz’s racing program.

He continued pointing out the factory components currently in his 5-second Mustang, saying that the factory hydraulic lash adjusters and primary timing chain tensioners, with a few modifications, are more than up to the task of surviving under the forces his formidable engines puts out.

He continued pointing out the factory components currently in his 5-second Mustang, saying that the factory hydraulic lash adjusters and primary timing chain tensioners, with a few modifications, are more than up to the task of surviving under the forces his formidable engines puts out.

A set of Ford GT lash adjusters will go a long way, the benefits of using these hydraulic lifters have led many performance builders to improve the potential of older modular cylinder heads with these pieces.

“As for secondary chains, of course, we have our own chains,” Mihovetz said. “We’ve found that the factory secondary tensioners and chains aren’t up to the task of living in the conditions we’re putting them through, as aftermarket chains are about 50 percent stronger that the stock chain. In most cases, if one of the timing chains break it is the result of a builder doing dumb stuff. The most common issues are not verifying the valvetrain setup, and using camshafts that are way too aggressive.”

The Downfall Of Stroker Rotating Assemblies

With strokers being all the rage in the world of small-block engines it didn’t take long for someone to drop a stroker crank into a Modular. But while this practice has been a viable option for years, how does this method of increasing cubic inches perform under the cover of a Modular?

“When it’s a stroker kit, there’s a window in which it can work, and there’s a window in which it does not,” Mihovetz adamantly explained. “In my 20-plus years of working with this engine platform, I haven’t seen anything from an off the shelf stroker assembly that impressed me.

The biggest underlying issue is that the length of the cylinder is too short to stand up to the increased stroke,” Mihovetz continued by pointing out. “Even in the existing structure, there is too much piston hanging out of the bottom of the hole and adding a longer stroke amplifies that issue. If someone sat down and took the time to engineer a proper stoker kit and made sure they could keep it alive and it would work pretty good, to a certain point.

As Mihovetz explained, the factory cylinder bores aren’t designed to handle the added stroke of these stroker kits.

Once you start going over 1,000 hp you hit a power threshold and the math just doesn’t support it,” Mihovetz concluded by saying. “The real issue is that a longer cylinder liner needs to be installed to accommodate the stroker components, and most guys that are buying these kinds of kits don’t have the means to install a set of custom sleeves that cost more than the rotating assemblies themselves.”

Boosting Up The Crank

I don’t understand where this belief that you need a billet crank came from. In 20 years of trying pretty damn hard, I never broke a factory forged Kellogg 4.6 crank, not once.-John Mihovetz

“I don’t understand where this belief that you need a billet crank came from. In 20 years of trying pretty damn hard, I never broke a factory forged Kellogg 4.6 crank, not once,” Mihovetz exclaimed. “I mean we did a lot of work to the crankshaft, but it wasn’t the lack of potential that made me switch over to the billet stuff. The reason that I designed a new billet crank with Bryant was it’s stiffer and a little easier on bearings, in comparison to the stock crank.

So, on the other side, you have the forged 5.4 Cobra Jet crank,” Mihovetz continued to explain. “Which is no different than any other 5.4 truck, the only difference in the Cobra Jet Crank is that it has dual keyways for the blowers. The only change that was made when Ford built the GTs in 2005 was they decided to eliminate the oil pump drive provisions at the crankshaft because they felt it was stronger.”

Mihovetz concluded our conversation by saying, “So, regarding power output, I limit 5.4 factory crank builds at 1,300 to 1,350 horsepower. I’ve found that the factory crank is not center counter weighted and was never made to spin very high, anything above 7,200 rpm and the crank really tries to tie itself in a knot. That’s the limitation of the 5.4 CJ crank, in my opinion. After making the jump over to the Byrant piece those issues are no longer present.”

Well there you have it, we visited some of the many misconceptions that are tied to the Ford modular engine. Durning our time with Mihovetz, we learned that the factory Kellogg crank has the capacity of transferring over 3,000 hp and laying down 6-second passes, that B heads are far more influential than any other Ford OHC V8, and that their potential was lost in translation somewhere. We hope you’ve gleaned as much as we have during these talks with John. Check back in as we aim to expand on our talks with the mod motor authority himself.