TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Don Weber, president of Engine Parts Group, the parent company of Engine Pro.

TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Don Weber, president of Engine Parts Group, the parent company of Engine Pro.

EngineLabs: More engines today are being built on a custom-order request with numerous suppliers. How can Engine Pros simplify the builder’s job or speed up the turnaround time?

Don Weber: The 30-plus Engine Pro warehouses provide most customers in the US and Australia next day availability for engine parts. Our broad product offering allows builders to source the majority of their needs from a single source, saving time and freight costs.

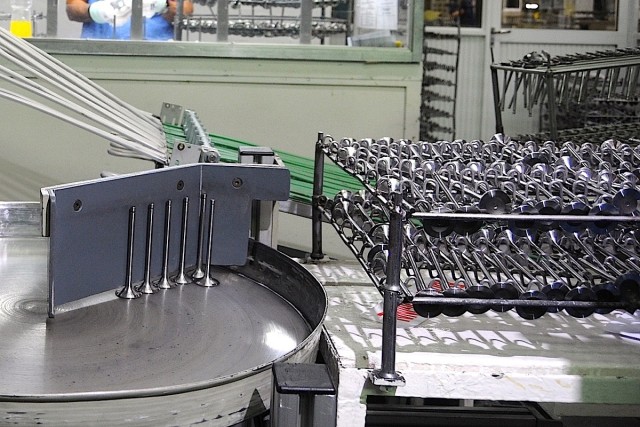

EngineLabs: Discuss the design strategy behind the Nitro Black valve line and how it differentiates from the other Engine Pro conventional stainless valve series.

Weber: Our goal with Nitro Black valves is simply to build the best stainless valves on the market today. We start with our best competition series valve, then use our exclusive liquid nitriding treatment to give it an incredibly smooth stem–which provides better stem-to-guide heat transfer and wear properties than ordinary stainless valves can provide. Our black nitriding is not a coating but a treatment that penetrates the surface and provides corrosion resistance so that exotic and corrosive fuels can’t harm the valve. Just like the nitriding on a crankshaft, our valves resist surface cracking and fatigue better than any other conventional stainless valve on the market today.

EngineLabs: Break down your customer split between race/performance builds and conventional rebuilds. What trends have you seen in each segment that are encouraging for the industry or should be taken as a warning sign?

Weber: Our customer base ranges from OE production rebuilders who never see any performance work all the way to exotic performance builders whose engines start at $20,000. Being broad based gives us the ability to do well regardless of the market climate and season. Conventional rebuild numbers are not as strong as they once were, due to engines lasting longer, but the average cost of a rebuild is much more as the complexity of engines has increased.

EngineLabs: Talk about the benefits of partnering with the sprint series and how the alliance can serve engine builders.

Weber: Engine Pro’s sponsorship of two of the most exciting racing series in the country (Must See Racing and Sprints on Dirt) provides brand awareness for all of our Engine Pro products and allows our customers to associate themselves with those brands. Our engine builder customers are our conduit to the racer and retail market and sponsorship and are just one of the ways that Engine Pro supports and provides marketing tools to its customer base.

Weber: Engine Pro’s sponsorship of two of the most exciting racing series in the country (Must See Racing and Sprints on Dirt) provides brand awareness for all of our Engine Pro products and allows our customers to associate themselves with those brands. Our engine builder customers are our conduit to the racer and retail market and sponsorship and are just one of the ways that Engine Pro supports and provides marketing tools to its customer base.

EngineLabs: You sponsor “Shop Solutions” in Engine Builder Magazine. What are your three favorite tips submitted by the readers?

Weber: We have been sponsoring and providing all the Shop Solutions for the Engine Builder Magazine column since 2007, so picking my three favorites from about 500 is not easy, but here are some of my favorites:

Grumpy Jenkins Trick: Twenty years ago I was lucky enough to have Grumpy Jenkins show me a great way to cut steel braided lines. He used a sharp wide chisel. This works great and leaves no frayed ends. Just put the hose on an aluminum block, use your sharp chisel and hit it like you mean it! — Jeff Beseth, BeezerBuilt, Inc., Newton Square, PA

Avoiding flat-cam syndrome: Along with the use of assembly lubes, break-in oils with ZDDP and a lifter-bore grooving tool, our shop adds one step before final assembly. With a bare, clean block we’ll put in the two end cam bearings and install the cam with only light oil. Next we install the lifters with only light oil. Install a bolt in the front of the cam and spin it quickly clockwise with a speed handle and observe each lifter’s rotating action. Use a felt pen to mark the lifters so it’s easier to see them. If you find any of the lifters not spinning, this could be a potential problem if it leaves your shop like that. Lifter bore or even cam bore alignment could be the problem. Many times the cam bearing bores get closer (fall) towards the crank centerline going front to back, (especially on BB Chevys) which in turn causes the taper on the cam lobe to be lessened towards the back of the motor. Zero or too little taper can keep the lifter from spinning, and this can cause the cam to fail shortly after fire-up. — Norm Johns, Norm’s Auto Machine, Petaluma, CA

Tootsie Roll solution: Someday you could find yourself at the track, out in the field, or at home in your garage needing to check piston-to-valve clearance after a cam swap or cylinder head change and there is no clay available. No problem, go buy yourself a Tootsie Roll, and after it sits in your pocket for 20 minutes or so it should be soft enough to use. — John Allen, Advanced Engine Machine, Bakersfield, CA