As fuel prices continue to climb, CAFÉ standards continue to increase and emissions requirements continue to squeeze engine and vehicle manufacturers; research and development is in high gear to find the next “big” solution.

Most people will agree that the fuel prices are more influenced by politics than they are business, most OEM’s and engine manufacturers are focused on research and development of engine and vehicle technologies than they are trying to fight fuel prices.

Most people will agree that the fuel prices are more influenced by politics than they are business, most OEM’s and engine manufacturers are focused on research and development of engine and vehicle technologies than they are trying to fight fuel prices.

Over the past decade, there have been enormous steps forward in fuel efficiency of gasoline engines but, unfortunately due to emission regulations, diesel engines have actually gone backwards. With the requirement for DPF (Diesel Particulate Filters), DOC (Diesel Oxidation Catalyst), and SCR (Selective Catalyst Reduction) diesel engines have become less and less efficient.

If we look at the governing formulas for efficiency, we would find that the spark engine cycle will always be greater than a diesel engine at the same compression ratio. The reason that diesel engines are more efficient is their high compression ratio’s compared to the lower gas engine compression ratios. Well, with these emission requirements, gas engines are now using direct injection and are able to run higher compression ratios, but diesel engines are run lower compression ratios to meet the new emission levels. If this trend continues, gas engines in production could actually be more fuel efficient than diesel.

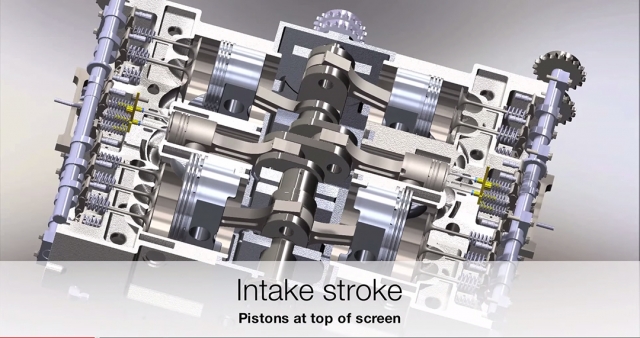

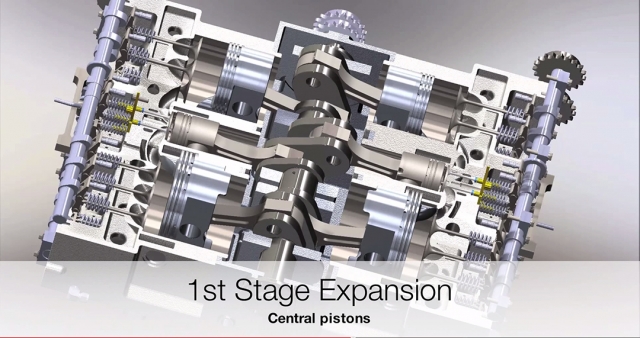

A new engine idea from Motiv Engines hopes to turn this trend completely around. The new engine being proposed by Motive Engines uses an ultra-high compression ratio of 56:1 to create an extremely efficient engine. This multi-stage engine achieves this extreme compression ratio thanks to a separate compression and combustion cylinder. The outer cylinders take air in and compress it in the first stage.

A new engine idea from Motiv Engines hopes to turn this trend completely around. The new engine being proposed by Motive Engines uses an ultra-high compression ratio of 56:1 to create an extremely efficient engine. This multi-stage engine achieves this extreme compression ratio thanks to a separate compression and combustion cylinder. The outer cylinders take air in and compress it in the first stage.

Then a valve opens, transferring that compressed air into the combustion cylinder, which compresses is more before fuel is injected and ignited. The compression cylinder and the combustion cylinder are of different sizes. The compression cylinder is much larger than the combustion chamber.

There are two reasons for the much smaller combustion chamber size. First, is the reduction in means less heat is lost to the cylinder walls. Secondly, the smaller size means the compression ratio can reach much higher ratios or pressures.

One of the many reasons why we don’t see compression ratios this high in a standard engine is because the heat would be tremendous. Ratios like this generate a lot of heat, but if the primary air is being drawn into a relatively cool cylinder, the air density stays higher. If the combustion cylinder is drawing in air, the remaining heat from the previous combustion, drastically affects the incoming air.

One of the many reasons why we don’t see compression ratios this high in a standard engine is because the heat would be tremendous. Ratios like this generate a lot of heat, but if the primary air is being drawn into a relatively cool cylinder, the air density stays higher. If the combustion cylinder is drawing in air, the remaining heat from the previous combustion, drastically affects the incoming air.

With this design, Motiv Engines’ has created a 4 stroke engine that fires every revolution like a 2 stroke engine. This is thanks to the two compression cylinders per single combustion cylinder.

Another very interesting concept with this engine, is the fact that the engine block and cylinder heads are cast as one, then bolted to a central block housing the mains and crankshaft. If they are able to go into production with this type of design, they would essentially be able to reduce their manufacturing cost thanks to the symmetry of the two sides.

This is a very interesting design and one of many that have been proposed over the past decade that could completely revolutionize how we power our vehicles. The initial estimates are that this engine will have a brake thermal efficiency of 52% (roughly 20% better than a gas engine currently in production and 10% better than a production diesel). For more information, please visit Motiv Engines.