Video Update: The Power Automedia video team talked to Jamie Allison, director of Ford racing, at the SEMA Show to get further insights into the car and engine. Check it out above!

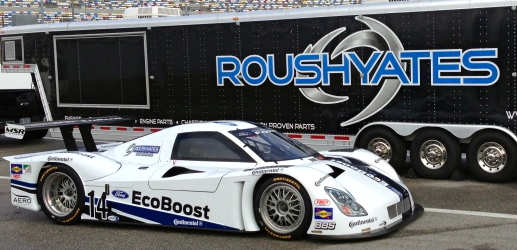

The 3.5-liter Ford EcoBoost V6 engine powering Colin Braun to a number of speed records yesterday is made up mostly of production parts and is nearly identical to the new race version that will run in the upcoming Tudor United Sportscar Championship series.

A Riley Technologies Daytona Prototype car owned by Michael Shank Racing set a Daytona International Speedway 1-lap record of 222.971 mph during a dedicated speed session. That broke the existing speedway record of 210.364 set by Bill Elliott in a Ford Thunderbird while qualifying for the 1987 Daytona 500.

The team also tentatively set world speed records for the 10-mile standing start at 210.018 mph and 10-kilometer standing start at 202.438 mph. Both records are subject to FIA certification.

“It was a challenging day,” said Braun said after the run. “The power in the new EcoBoost engine was incredible, and it was amazing how fast it came up to speed on the runs. Our first run this morning was 209 mph, and it was an edgy drive at that speed. I can only imagine how edgy it was for Bill Elliott doing those speeds in his Thunderbird stock car.”

The record runs come on the heels of Ford announcing that the 3.5-liter EcoBoost will replace the venerable 5.0-liter “cammer” V8 that had been used in Grand Am DP racing since the series began in 2003 and when a Ford engine won that year’s Rolex 24-hour race. (Grand Am has now joined with ALMS to compete for the Tudor United Sportscar Championship for next year). The Daytona Prototype class is unique in that a number of different engines, including BMW, Lexus, Honda and Porsche, are certified for competition but highly regulated to bring parity to the field.

The record setting car had special Continental tires that were lighter, offered less rolling resistance and sported a harder compound than a typical race tire. The chassis and suspension were also optimized for the oval record runs, then the team switched over to a road-racing setup and began testing for the upcoming season. The engine also needed a little retuning.

“Our attempt was to keep this engine as close as possible to what we were going to race next year,” says John Maddox, the road racing program manager at RoushYates Engine. “That doesn’t mean we might not have added a little more boost!”

Development of the 3.5-liter EcoBoost for the DP class began more than two years ago as the 5.0-liter engine was showing its age. Although Jorg Bergmeiseter won the 2006 driver’s title in a Ford-powered DP car, Ford never won the engine-manufacturer title.

“The 5.0 had run its course,” Maddox tells EngineLabs. “It was basically an bored-out 4.6-liter from the ’99 Cobra Mustang. The ‘cammer’ motor, per se, no longer existed.”

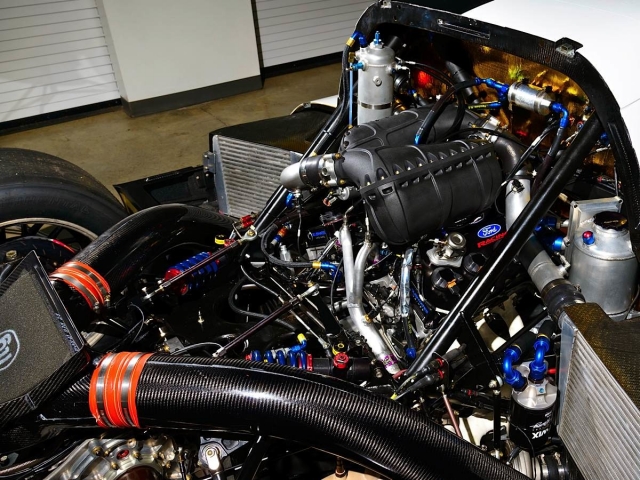

At the time, Ford had started developing an EcoBoost engine for LMP2 racing to compete against the twin-turbo Honda. Grand Am officials heard about that project and suggested that the engine be submitted for certification. Ford knew it needed a new engine for sports car racing, and the EcoBoost was a better choice than modifying the 5.0-liter Coyote V8.

Production relevance

“The series wants more technology and more production relevance,” says Maddox. “And we needed something that excited our company and Ford.”

Grand Am officials have access to the NASCAR Research and Development Center where engines are thoroughly tested and regulated to even out the horsepower numbers as well as the torque curve.

“In the beginning, Grand Am wanted the power curve to mimic our 5.0-liter. Same power and get as close to the torque curve,” says Maddox. “Then they upped the max horsepower by 50 for 2014. Now we’re looking at 600 SAE.”

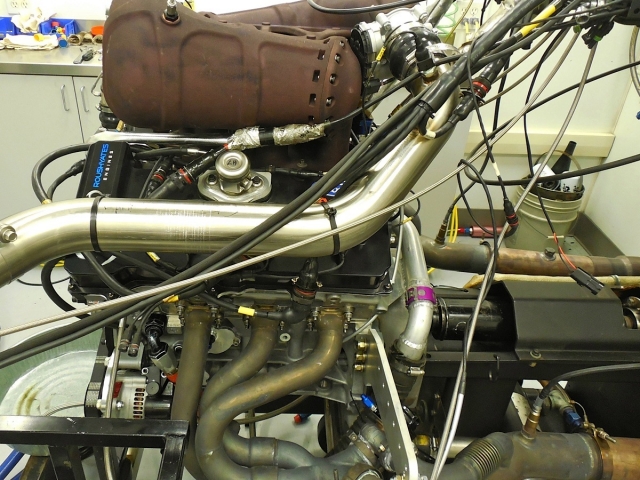

RoushYates says the new EcoBoost race engine will utilize “60 to 70 percent” production components, including the block, cylinder heads and valvetrain.

“The camshafts will be a little different,” says Maddox, noting the engine will retain the stock 3.64 x 3.49 bore and stroke. “Otherwise it’s a race crank, rod and piston. The fuel system wasn’t up to the capacity, so we had to add another direct-injection pump and go to a larger injector.”

RoushYates had to upgrade the turbos and direct-injection system, but say 60 to 70 percent of the stock engine carries over to the race version.

Few modifications were required on the heads. The intake port is as-cast with some bowl work, and the exhaust port was opened up near the manifold flange. RoushYates also installed a dry-sump oiling system that was basically a carryover from the 5.0-liter engine. Providing the boost will be a pair of Borg-Warner EFR turbos that are larger than stock, but much of the induction system is rather conventional for a race engine.

“This engine is relatively low boost, less than one atmosphere,” explains Maddox, noting that it’s set in the range of 12 to 13 pounds. “The manifold and induction rely on the fact that it acts like a naturally aspirated engine [with regards to] runner length and runner size. After final submission [to Grand Am], we’ll be given a boost number.”

Ford will have the option of adjusting boost levels, according to the track altitude, but the development team eliminated the variable valve timing mechanism.

“In the power range we’re running, it’s not very effective,” says Maddox. “It’s effective in the 1,800 to 2,000 rpm range. Very seldom do we see a 2,000-rpm swing on the race track.”

RoushYates engineers addressed three primary challenges in developing the EcoBoost engine for racing: direct injection, loads on the rod and piston and exhaust temperatures.

“We went to our big brothers in the Cup shop and leaned on those engineering resources to work through the issues,” says Maddox.

RoushYates worked extensively on piston design and calibrating the direct-injection but much of the valvetrain was left stock.

“On piston design, in particular, we drew from experience on the NASCAR side,” says RoushYates CEO Doug Yates. “It’s been fun within the company to work on multiple projects.”

The team also had to adapt the required Bosch ECU to the fuel system and calibrate it precisely.

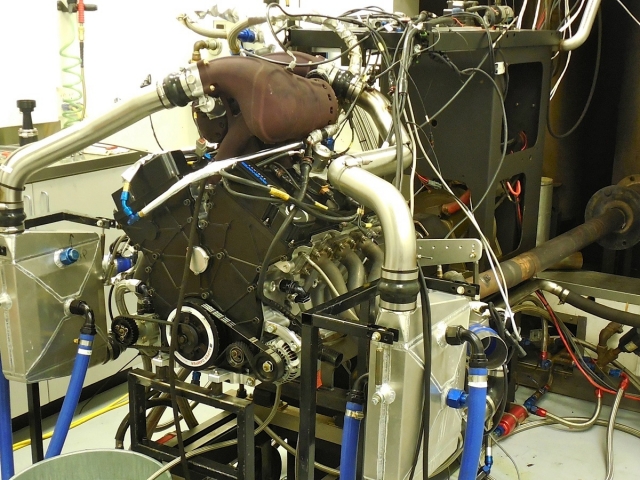

Once the power levels were achieved, durability was addressed with extensive testing conducted at Ford’s “17G” AVL dyno-test cell.

Thousands of Daytona simulation laps

“We ran an 885-lap Daytona simulation in the middle of July,” says Maddox. “We’re going back next month for a 1,400-lap durability test. If needed, we’ll go back in December.”

“Since this engine was so new to us,” reminds Yates, “it really was a discovery phase. It was the first time we had direct injection and turbos on an endurance test.”

Packaging the new EcoBoost engine was also presented a challenge to the team. Engineers are still working on heat-management issues as the car prepares for its first race at Daytona in 2014.

The primary survival element focused on piston and rod construction to survive the increased cylinder pressures. Yates says Ford provided a strong foundation with piston-cooling provisions.

“But it was really about wrist-pin stress levels,” adds Yates.

“In the 5.0 we divided horsepower between eight cylinder,” notes Maddox. “The cylinder pressure was significantly lower than dividing 600 between six cylinders.”

“In the 5.0 we divided horsepower between eight cylinder,” notes Maddox. “The cylinder pressure was significantly lower than dividing 600 between six cylinders.”

Testing and development will continue up to the start of the Rolex 24 Hour race. Adapting the engine to the Riley chassis wasn’t difficult as the cars are designed so that the engine isn’t a load-carrying member — as in other prototype cars. However, heat management under the body shell remains a concern.

“There has been a lot of hard work by a lot of people to get it to where it is today,” sums up Maddox, “but this EcoBoost engine is relevant, state-of-the-art production technology in racing.”