High performance and racing engines operate in harsh conditions that are taxing on oil systems. Stock-type oil pans running under racing conditions will suffer noticeable oil pressure losses and possible engine damage. Enthusiasts experience measurable differences in oil control and pressure when stepping up to oil pans designed for specific applications.

High performance and racing engines operate in harsh conditions that are taxing on oil systems. Stock-type oil pans running under racing conditions will suffer noticeable oil pressure losses and possible engine damage. Enthusiasts experience measurable differences in oil control and pressure when stepping up to oil pans designed for specific applications.

Due to the uniqueness of each application and the differences among different engines, identifying and designing a “one-size-fits-all” high performance oil pan is not possible.

Canton Racing Products designs oil pans for different engines and applications with a focus on the unique demands of oil control for each type application.

“For street applications where there is little demand placed on the oiling system and pressure control is not an issue, highly engineered oil pans will likely make minimal difference in oil pressure,” says Mike Zeranski Jr. of Canton Racing Products. “However, racing applications can certainly benefit in oil control and oil flow to the pickup.”

Racing applications can certainly benefit in oil control and oil flow to the pickup.

— Mike Zeranski Jr.

An Introduction to Canton

Canton has been manufacturing oil pans since 1981, starting in a small Connecticut garage building specialty oil pans for local auto racers. Not surprisingly, Canton’s popularity grew as their pans developed a reputation for both horsepower and quality.

“Our oil pans are TIG welded, rather then MIG welded. The TIG welding process takes more time and skill but ensures more even heat and penetration through out the welding process. This result is better quality welds with less possibility for leaks and cracks,” says Zeranski.

Starter clearance, header clearance and ground clearance often play into the oil pan design and typically dictate the pan’s outer dimensions.

How It’s Made

“We have pans with observation windows built in that allow us a visual of how the oil is moving in the pan and coming off the crankshaft,” says Zeranski. “We can see how our crank scrapers, oil recovery pouches, windage trays and oil pan baffling work while the engine is running at different rpm and angles.”

Early in the design phase, Canton engineers identify a particular engine and application, and then take a look at the existing effects on oil control.

“The first thing considered is the chassis and the application. These two items identify the limitations placed on the oil pans. The need for starter clearance, header clearance and ground clearance can often play into the oil pan design. These factors will typically dictate the pan’s outer dimension,” explains Zeranski.

“The baffling and power saving-features added will depend on the level or performance desired. Proven baffling and power-saving design features can be adapted to each unique application. We then work directly with engine builders, racers and car builders to test fit and evaluate these designs,” he adds.

It’s a Balancing Act

The obvious starting point is selecting a pan for the intended application. Canton Racing Products makes approximately 300 different oil pans for various types of applications. With product lines including pans for circle track racing, drag racing, road racing, trucks, marine use and street use, each style of oil pan has strengths for the intended application. Selecting between oil control and power functions in an oil pan is generally application specific and often a balancing act of both functions.

Street/Economy Oil Pans

Street cars are subject to turning, acceleration and braking that can cause the oil to flood on one side of the oil pan. Repeated movement of the oil causes wavelike sloshing of the oil in the sump, which can dip the crankshaft into the oil or uncover the oil pump pickup. Excess oil on the crankshaft adds rotating weight and reduces horsepower. A good economy street pan will probably offer a deep sump only. Some of these types of oil pans include a one-way screen windage tray or crank scraper. These pans are almost always stamped steel.

An oil pan designed for street and strip use is — by it’s very nature — more aggressive in the power function and provides adequate oil control to prevent sloshing and oil starvation. Most street/strip oil pans will also incorporate a windage screen and baffles with trap doors. These dual-purpose pans are usually fabricated for deeper sumps and are purpose built for specific chassis. A deep sump will keep a larger column of oil over the oil pump pickup, which prevents any possibility of oil starvation. The larger column of oil will dissipate heat as it waits to be picked up by the pump and moved through the system.

Drag Race Oil Pans

Drag race oil pans are designed to maximize power by keeping excessive oil off of the crankshaft and controlling the windage generated by the rotating crankshaft. Oil on the crankshaft adds rotating weight and uses power. At high rpm, there are literally sheets and ropes of oil clinging on the crankshaft. These ropes are flung off of the crankshaft and bounce against the side of the oil pan and ricochet back onto the crankshaft.

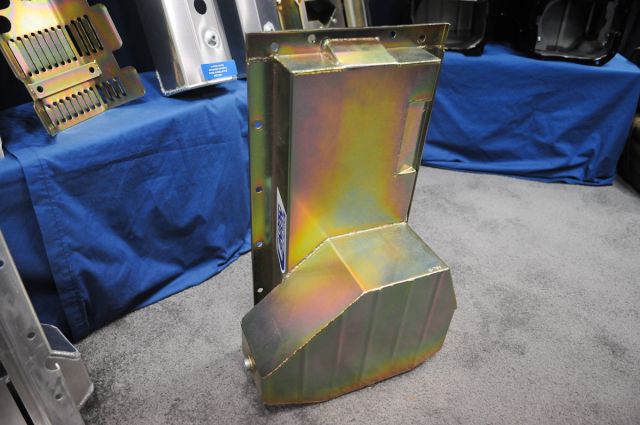

Canton’s drag race oil pans are designed with an oil recovery pouch to control the oil splashing and route the oil back to the sump, a windage tray, and a crank scraper. Some oil pans include other devices to control the oil, such as a check-ball system in place of the trap door.

Oil pans designed for drag racing provide an adequate supply of oil during quick acceleration while keeping the rotating weight down. Some drag race oil pans are made of welded or fabricated aluminum to take advantage of weight savings.

Controlling the Oil in the Pan With Trap Doors and Baffles

“A lot can happen inside the oil pan while cornering, breaking and accelerating. A long gradual high-g corner can push the oil in the pan to one side while a quick series of corners can really get the oil splashing. We design our windage trays and slosh baffles to combat a range of vehicle motions,” says Zeranski. “We use a combination of precisely positioned trap-door baffles, oil runners, and slosh baffles to control the oil in the sump and direct it to the pickup. Trap-door baffles are designed and positioned to open and allow oil to easily flow towards the pickup and close to prevent oil from flowing away from the pickup. When motion causes oil movement the oil runners direct oil toward the trap door baffles.”

The concept is rather simple — keep the oil at the pickup. Trap door baffles are designed and positioned to open and allow oil to easily flow toward the pickup and to close to prevent oil from flowing away from the pickup. Under cornering force, the doors will keep the oil from shifting in the pan and keep it at the pickup.

Power Saving Design Features

The bottom of a crankcase is a pretty harsh environment with pistons moving up and down inside your engine creating a pumping motion of air coming down into the crank case at thousands of revolutions per minute. The crankshaft also acts as a propeller, spraying oil everywhere, including the walls of the block. This is bad and good. Too much oil splashing around tends to cause issues.

Imagine your crankshaft spinning at 6,000 rpm with all these parts spinning around. Considerable turbulence is created by these moving parts. With moving air hitting oil, it causes the oil to splatter and also creates air bubbles in the oil itself. It is known that windage can turn up to three quarts of your engines oil into a dirty tornado in the bottom of your crank case. Canton’s power saving design features can prevent this tornado from robbing power.

Recovery Pouch

The oil pan’s recovery pouch extends the right side of the pan out away from the crankshaft, creating an open pocket for oil coming off the rotating assembly to collect and drain into the sump. This thins out the heavy atmosphere of oil in the crankcase allowing the crank to spin easier.

Windage Trays

Windage is the flow of air within the crankcase. Each time a piston comes down in the cylinder bore, the air under it is pushed into the crank area. Each time the piston goes up, the air is being pulled behind it. At the same time, the rotating assembly is spinning and churning the air and adding oil into the mix. The windage tray keeps the windage around the crank from the oil in the sump area. It allows the oil coming off the crank to easily enter the sump without the windage affecting the scavenging of oil already in the sump. The windage tray also keeps any oil in the sump from getting into the rotating assembly during vehicle motion.

Crank Scrapers

The crank scraper extends out away from the pan mounting rail toward the crankshaft. The crank scraper is designed to catch oil spray coming off the crankshaft. Like the oil recovery pouch the crank scraper thins out the atmosphere of oil around the crankshaft and frees up horsepower.

Pickups and Pumps

Oil control in the pan dictates that oil is removed from the rotating assembly and guided to the oil pickup for use. Oil pickup clearance from the bottom of the oil pan becomes a relevant issue if there’s too little clearance.

You can calculate the clearance by measuring the internal pan depth and measuring the distance from the block’s pan rails to pickup bottom. The difference between the two measurements will provide the pickup to pan clearance. Gaskets will add some additional clearance. Here are Canton’s recommended pickup-to-pan clearances:

- Ford Pans: 5/16 to 3/8-inch (.312-.375)

- Chevy Pans- 5/16 to 3/8-inch (.312-.375)

- All Others 5/16 to 3/8 -inch (.312-.375).

Deep sump pan pickups are submerged deeper into the oil are less sensitive to clearances. Deep sumps may have clearance up to a 1/2-inch.

Sump area, baffles, trap doors, windage trays and crank scrapers all help manage the balance of oil control or power based on the intended application.

Summary

Oiling is the engine’s life blood and the lubrication system should be right if you want the engine to have a long, dependable life. The harder you drive and the more power your engine makes, the better the oil control needs to be. Understanding how oil is controlled in the oil pan is the first step in designing a lubrication system that will support your engine’s functions.

For more information on oil control, oil pans or lubrication systems in general, visit Canton Racing Products at www.cantonracingproducts.com, or call their tech line at (203) 481-9943.