Hardcore engine tech and performance-minded gearheads know vastly more about how an engine works, and more importantly why, than the average Toyota Camry buyer. Hence, they’re far more skeptical of trick-of-the-week “quick fixes” to common mechanical problems than the rest of the crowd; and that skepticism is especially vehement when it comes to oil and other fluid additives.

Hardcore engine tech and performance-minded gearheads know vastly more about how an engine works, and more importantly why, than the average Toyota Camry buyer. Hence, they’re far more skeptical of trick-of-the-week “quick fixes” to common mechanical problems than the rest of the crowd; and that skepticism is especially vehement when it comes to oil and other fluid additives.

For decades, additives have inundated TV airwaves and magazine ads, offering miracle solutions to common automotive issues like oil usage or burning, hard starting, poor fuel mileage, better performance, reduced emissions and just about everything else short of curing baldness. And they often come with testimonials from well-respected automotive personalities so they must be legit, right? To the average Joe who doesn’t even know what oil is in his car, that could be the conclusion.

zMAX has conducted numerous tests on its products with results and explanations available on its website.

However, astute engine builders know that that racing hero may often be nothing more than a paid monkey who gets big sponsorship dollars but in his heart knows he’s pitching snake oil. At a small industry event about 20 years ago, Smokey Yunick all but said as much, and the chuckling and outright guttural laughter amongst the journalists and engineers in the room made the uncomfortable squirming of the advertiser’s marketing guys just that much funnier.

zMAX Micro-lubricant is sometimes lumped into this category of unsubstantiated miracle solutions, quite likely due to its high-profile advertising campaigns that make bold and confident claims. However, unlike many other lubrication formulas or so-called additives, zMAX has a history founded in science and a rather extensive resume of lab tests that prompts EngineLabs to ask even more questions.

We’d see a 5-horsepower increase after three days of hot-cold run cycles.–Ed Rachanski Jr, zMAX

The story somewhat starts in the era of Enrico Fermi, an Italian physicist and key player in the Manhattan Project that developed the first nuclear weapons during WWII. Some of the Manhattan Project’s development work took place at the University of Chicago (UC), near where Joe Lencki grew up. A lifelong hot rodder and self-taught engineer, as well as future engine designer and Indy Car builder, Lencki did some mechanical work on the side for UC scientists, becoming friends with Fermi along the way.

Fermi, as a side project to his day job of controlling nuclear reactions, developed an additive to reduce friction in internal combustion engines. Some could say it was to help the military aircraft that would eventually carry the bomb. Through their friendship, Fermi knew Lencki was into racing and engine building, so when the Manhattan Project got to the point of dominating all of his time, Fermi gave Lencki his secret additive formula for his own use. Lencki was also sent to the South Pacific island of Tinian to oversee the maintenance on the B-29 Superfortress engines in the planes that conducted the war-ending missions over Japan.

That’s A.J. Foyt on the left with Joe Lencki. Foyt was an early adopter of Lencki’s Speedway Cocktail.

Lencki utilized the formula in his race engines at Indy and also in a “Speedway Cocktail” that some other racing friends were allowed to use. He called the additive Lenkite. It was designed to improve wear, particularly on cold-starts, in his Lencki-6 Indy engines, which were stretched versions of the Offenhauser 4-cylinder. With his history in the aircraft industry, Lencki also received FAA approval for his Lenkite based on rigorous in-field testing that showed significant wear reduction in airplane and helicopter engines.

Now marketed under the zMAX name by Oil-Chem Research Corp. in Charlotte, NC (a subsidiary of Bruton Smith’s Speedway Motorsports Inc.), the formula still remains proprietary. However, officials say it does not contain Teflon, graphite or similar substances. It starts as highly refined mineral oil, not a synthetic, and the molecular structure is further refined to create what zMAX calls a “micro-lubricant.”

Here’s where the lines between marketing claims and technical facts are sometimes hazy. zMAX officials are quick to point out, as Lencki did, that zMax does not treat the oil, it treats the metal. The engine oil is nothing more than a delivery vehicle to carry the zMAX formula to the engine’s metallic parts.

zMAX is a “micro lubricant” designed to penetrate into smaller openings in the metal that conventional oils can’t.

‘Soak-in’ period needed

With this strategy, zMAX can be used in petroleum or synthetic oils. Once the formula reaches the metal, zMAX officials say it works by penetrating into the metal to protect it from scuffing (and therefore wear). That action is also said to disperse varnish, carbon and other deposits. The objective, according to zMAX, is that nothing will stick to the metal once it’s treated. This is most beneficial on cylinder walls, pistons and rings, valves and guides, camshafts and lifters, bearings and pretty much anything that sees metal-to-metal contact. zMAX stays with the metal once the oil drains back, but not forever—eventually, its effects will diminish and replenishing the oil system is needed (every 50 hours as in the case of aircraft engines), according to the company.

zMAX says a “soak in” period is required to penetrate into the metal. The formula works best when the parts are warm or up to operating temperature, which helps open the metal’s pores. Also, the more porous the metal the deeper the penetration; in other words, aluminum rods and pistons will soak up zMAX quicker than a crankshaft or cylinder wall. zMAX has been referred to as oil you can’t wipe off, no matter how hard you try.

The formula’s benefit’s echo those boasted for numerous other products: reduced wear on vital parts; better dependability and longer engine life, improved fuel efficiency, lower emissions and restored performance. In addition, zMAX claims it cleans and lubes fuel pumps and injectors, conditions the combustion chambers and helps remove varnish and deposits from valves, pistons and other surfaces, as well as preventing grime from coming back.

Joe Lencki used the formula given to him by Enrico Fermi in his racing engines, including his own 6-cylinder design based on the Offy.

Sometimes supporting the zMax claims are “before-and-after” or “with-and-without” photos; again, similar testimonies have been offered by other lubricants. But unlike some other companies marketing lubrication products, zMAX has conducted tests with its products and vigorously offers technical testimony to support its claims. So, EngineLabs posed the following questions to Ed Rachanski Jr, a technical officer at zMAX, to gain additional technical insight into the best uses for the product:

Engine Labs: First off, many people lump zMAX into the “snake oil” pile with all other additives, whether they work or not. What about that label, and why is it true or untrue?

Ed Rachanski Jr: It’s important to know that zMAX is not an additive but is classified as a “micro-lubricant.” To clarify this, SAE J357 OCT 99 provides this definition of an oil additive: “A lubricant additive agent is a material designed to enhance the performance properties of the base stock or to improve the base stock properties that do not naturally exist with the base stock.” Clearly zMAX does neither of these two functions, as it’s not designed to improve or enhance any qualities of the engine oil. Introducing it into the engine oil is merely the means to transport zMax directly to the engines metallurgy.

EL: Can you think of an engine problem, something existing like poor ring seal or guide/bearing wear, that zMax can solve, even temporarily?

Rachanski Jr: As an example, zMAX’s ability to provide positive lubrication as it dissolves and disperses performance robbing deposits was proven in a controlled field test using GM Northstar engines with oil consumption problems. zMAX solved the oil consumption in these engines by 1) dissolving the carbon on the pistons and ring lands. 2) Helped maintain the critical oil film sealing between the pistons/rings and cylinder walls. This resulted in optimum combustion efficiency, which has a direct effect on fuel consumption, horsepower and emissions.

EL: Does zMAX really help a race engine that is torn down and refreshed a minimum of once a year? Or is it meant more for preventative maintenance on daily drivers or tow rigs?

Rachanski Jr: Using zMAX in the oil system had several clear benefits that we experienced firsthand back when we were running the Olds Aurora V8 in the Indy Racing League. By using the zMAX right from assembly and dyno run-in, we’d see a five-horsepower increase after three days of hot-cold run cycles.

On race weekend and at the end of the day, we would remove the spark plugs in a warm engine and spray zMAX onto the cylinder walls and bump the motor over to help keep a fresh film of zMAX for the next day’s run. This helped keep the “critical oil film seal” between the pistons/cylinder walls to obtain and maintain our combustion chamber performance throughout the race.

This photo, supplied by Oil-Chem Research, shows a valve after use with (left) and without (right) zMax in the oil.

The zMax actually made the engine get stronger as the race went on as evident by our 1997 Phoenix 200 victory with driver Jim Guthrie. The engine compression leakdown numbers at the end of the race were much better than the other teams engines without using zMAX. For weekend warriors and other racers who don’t rebuild their engines after each race, we know that the product helps keep a better performance baseline for extended race sessions. Also, teams will use the zMax in their transporters and tow rigs for optimum preventative maintenance.

EL: Since zMAX treats the metal and not the oil, in the case of a disassembled engine, can the active metal treatment ingredient in zMAX be used once on the bare parts prior to assembly, and is it more or less effective than just dumping a bottle into the oil fill?

Rachanski Jr: On our race and aircraft engines, we would heat our parts to 200 F on a metal tray, remove and then spray 100 percent zMAX on them with an overnight cool down. For a new engine with freshly machined surfaces, the zMAX would help reduce excess frictional surface heat during the break-in period.

All those hot jagged edges damaging the oil resulting in brittleness and a loss of flexibility on the machined surfaces will hinder performance for the rest of the engine’s life. zMAX definitely helped keep our engines cooler under hot temperature break-in conditions and then did a great job of keeping the engines’ performance baseline from run to run. Using zMAX right from assembly, to dyno run and following up with use in the oil system will cover all the important aspects in providing better heat transfer and cooler working surfaces in your engine.

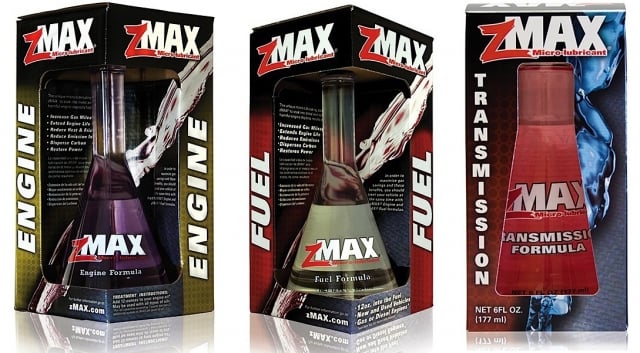

zMAX formula is marketed for oil, fuel and transmission applications, although the company says the formula is the same.

EL: How can zMAX help improve engine break-in when a proper assembly lube is already in place?

Rachanski Jr: Our experience using zMAX in addition to motor oil during break-in for any engine has resulted in less wear immediately as we learned from post-run teardown inspections. The zMAX does keep friction surfaces cooler while the metal is new and being broken in. As mentioned previously, too much heat during this critical period while metal is new and seating itself into its job can cause brittleness, loss of flexibility and can break down under sudden and severe strains which can create scuffing and galling. With the use of zMAX during break-in, we had achieved a dramatic reduction in wear on all our machined moving surfaces regardless of what type engine it was used in.

EL: How much is used in a typical 7-quart oiling system? Full bottle, half bottle, or what?

Rachanski Jr: For a typical 7-quart oiling system, use a 12-ounce bottle of zMax in addition to the factory fill level. When the engine is started, the zMax will begin by using the motor oil as a carrying agent to get zMAX to and into the metal surfaces. The hot and cold engine cycles (run and cool overnight) will help the zMAX molecules soak into the metal sub-surfaces.

I would recommend that for a racing application, whenever you change the engine oil add a fresh 12-ounce bottle of zMAX. Keep in mind that using zMAX is like having a sub-surface well of oil that will keep weeping out, therefore it does need to be replenished for continuous protection that will stay with the metal insuring positive lubrication during running or storage conditions.

EL: There are several different zMAX products for the engine oil, fuel, automatic transmission fluid, and gear oil applications. Are they different products or is it all the same?

Rachanski Jr: The zMAX formula is the same for all products. It’s color-coded and placed into different bottles for instruction and application purposes.

EL: You also have AvBlend for the aircraft industry. Is it the same stuff as zMAX?

This is one of the engines used for testing and certification of zMax at the Oil Chem Research facility.

Rachanski Jr: AvBlend and zMAX share the same micro-lubricating performance benefits, but the products are manufactured separately for quality control measures.

EL: In our research we learned of a Federal Trade Commission (FTC) lawsuit happening. It’s even called out on your own website (zmax.com/ftc). From where did that lawsuit originate, and after all the testing and subsequent court order, were there any claims you had made previously for zMAX that you could no longer make?

Rachanski Jr: The FTC lawsuit originated from zMAX’s independent marketing company placing a specific percentage number next to the fuel mileage improvement claim, which is not allowed because of the many variables facing the average motorist. zMAX performed extensive ASTM/SAE testing to support their performance claims and was allowed to continue making all of their original performance claims with the exception of removing a specific percentage number with the increases fuel mileage claim.

Bottom line

In summation, there is substantive historical background to the formula’s inception and laboratory validation to give zMAX enough credibility as a worthwhile lubricant. The best use of the product often falls behind the veil of wild marketing claims for oil-related additives or enhancements. No product is a miracle cure for all engine ailments, but the evidence suggests that zMAX can offer options for engine builders seeking additional performance — whether through pre-treating metal surfaces to reduce friction or maintaining a cleaner working environment for critical parts.

In a competitive environment that seeks to 10 ways to find one or two repeatable horsepower — as opposed to the old days when you could find 10 or 20 horsepower at once — reducing friction and dealing with parasitic losses are priorities. Different lubricants — even mature formulas like zMAX — certainly have the potential to help in the right situation.