Building an engine that’s capable of running 100-plus miles per hour on the water is no easy feat, but engine builder Andy Holman of Performance One has just the ticket on this big-block Chevrolet built for a competition ski boat.

Ski boat racing is one of the most insane competitions we can imagine; the boat runs monster speed while towing a single skier on the back for long distances – potentially 45 minutes to an hour long or more depending upon the particular event.

This ski boat engine is destined to find a home in Performance One customer Howard Hogans’ 21-foot boat, and is slated to compete in a number of ski race marathon events in the 2015 season, including a trip across the pond to compete in New Zealand. The boat averages 80-85 miles per hour in the turns, with runs down the straights cranking up over 100 miles per hour. As one might imagine, longevity is important in an application like this.

This ski boat engine is destined to find a home in Performance One customer Howard Hogans’ 21-foot boat, and is slated to compete in a number of ski race marathon events in the 2015 season, including a trip across the pond to compete in New Zealand. The boat averages 80-85 miles per hour in the turns, with runs down the straights cranking up over 100 miles per hour. As one might imagine, longevity is important in an application like this.

“We have to be able to meet a certain horsepower goal because of the speeds we run, but longevity is also very important. They will run 4,500 to 5,000 rpm steady for an hour, and we have to have something that will live for that time period without eating itself,” says engine builder Andy Holeman.

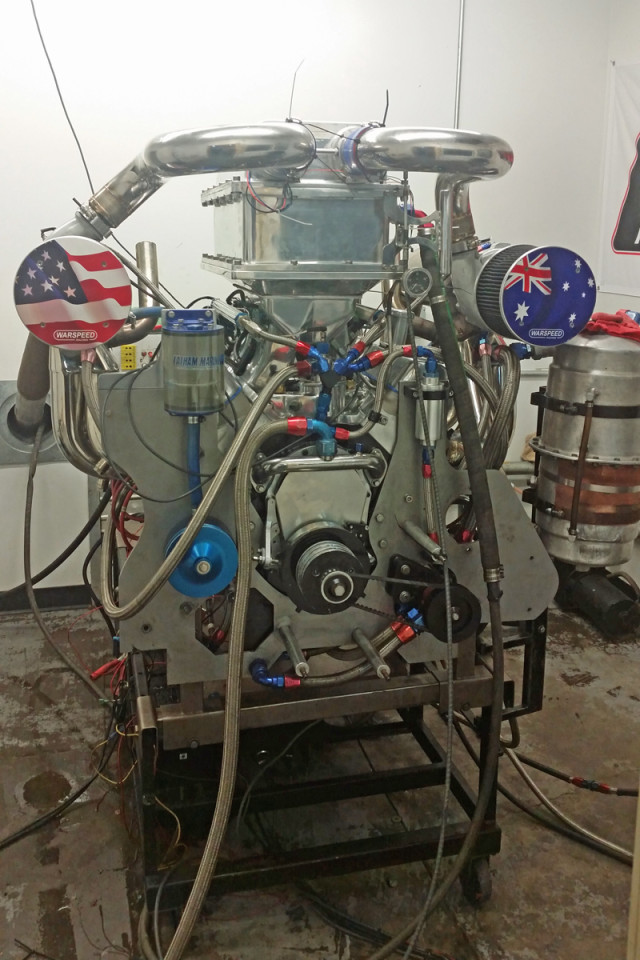

The engine makes use of a dry sump oiling system and a number of other tricks designed to keep it alive under such harsh conditions. There are piston oilers and spring oilers, and Holeman mentions that they don’t use any restrictors in an effort to keep oil in the top end of the engine to keep the valvetrain well lubricated.

“You have to run a little less lift on the camshaft, they have to have easier ramps on the lobes, things like that,” he says.

The engine pulls to 6,000 rpm, and that limit is due solely to the use of the Mercury #6 outdrive, which doesn’t live well past that rpm level, but is necessary for fitment into the boat.

“If you turn them any more than that they start to spit the guts out. We can only turn them so hard,” says Holeman.

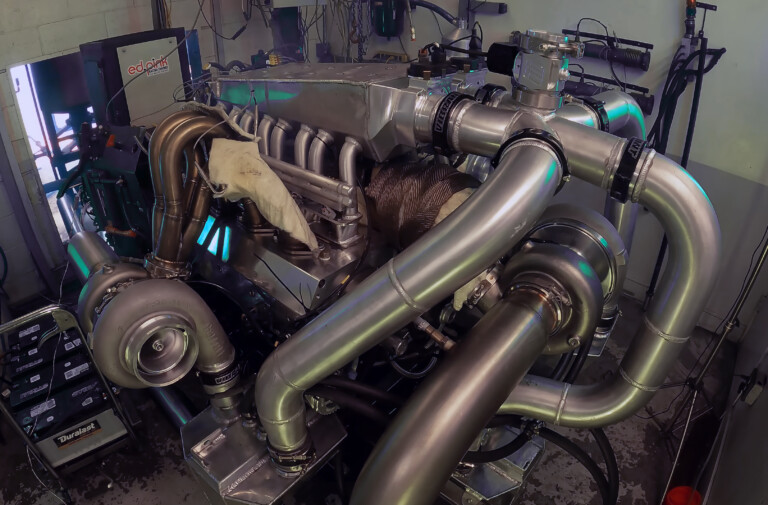

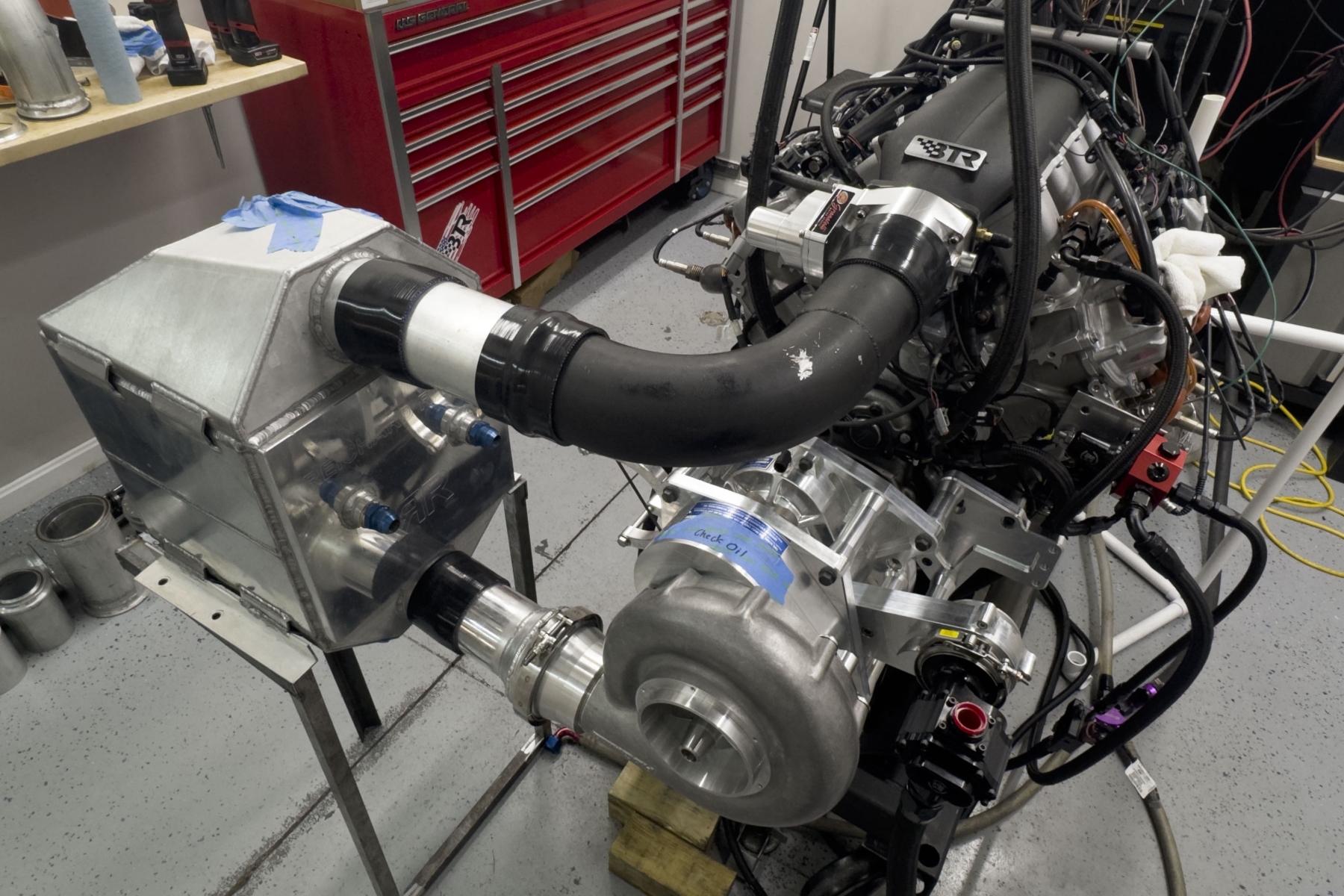

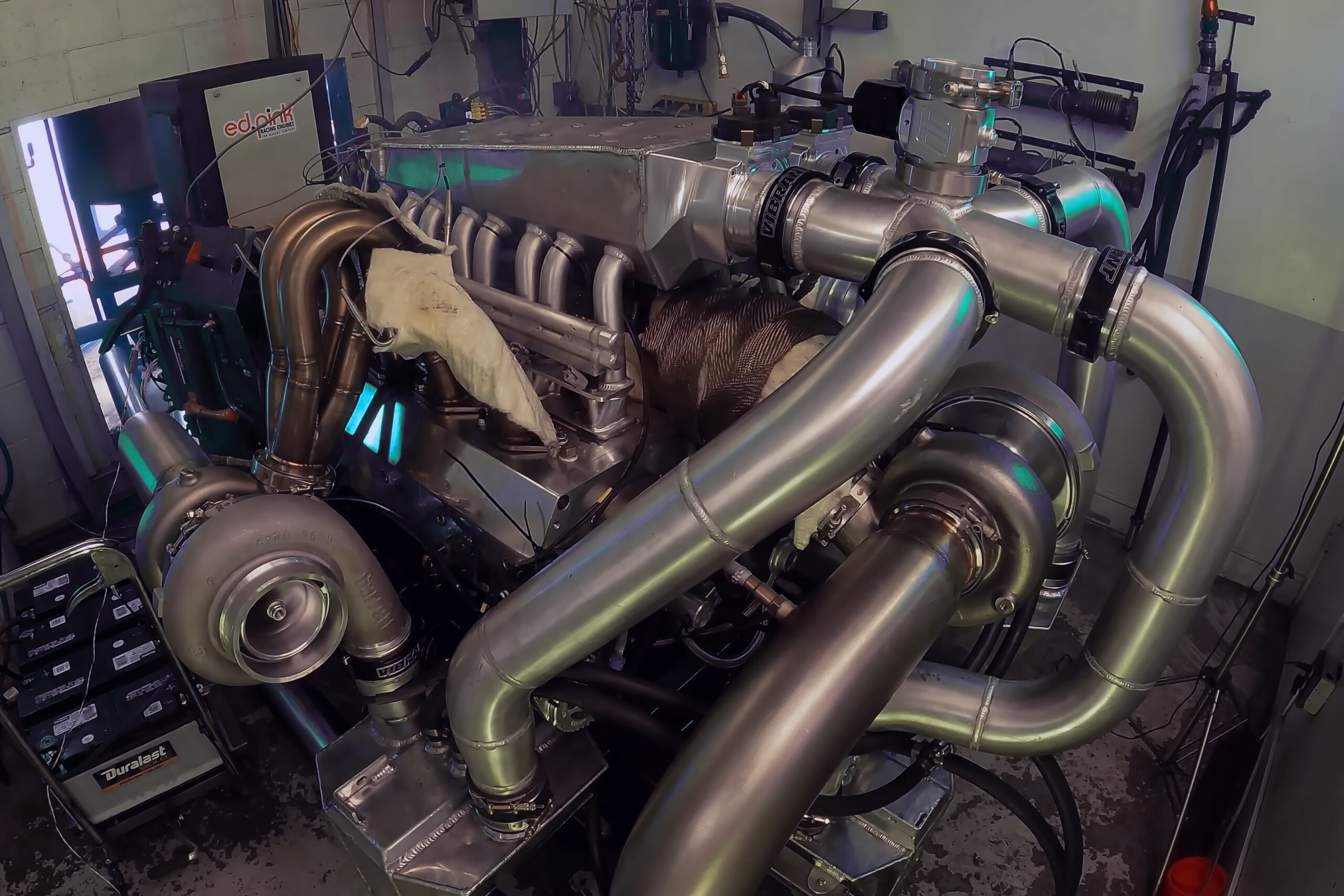

The engine is based around a Dart engine block and a pair of the company’s 355 CNC cylinder heads. A 4.375-inch stroke Callies forged steel crankshaft and Callies connecting rods are also used, with hard-anodized Diamond pistons also onboard. A custom Erson camshaft actuates the valves.

Also used in this application is a set of T&D steel rocker arms along with Smith Brothers pushrods to keep these parts alive without fatiguing. According to Holeman, aluminum rocker arms can present issues with longevity as the cycle life goes up.

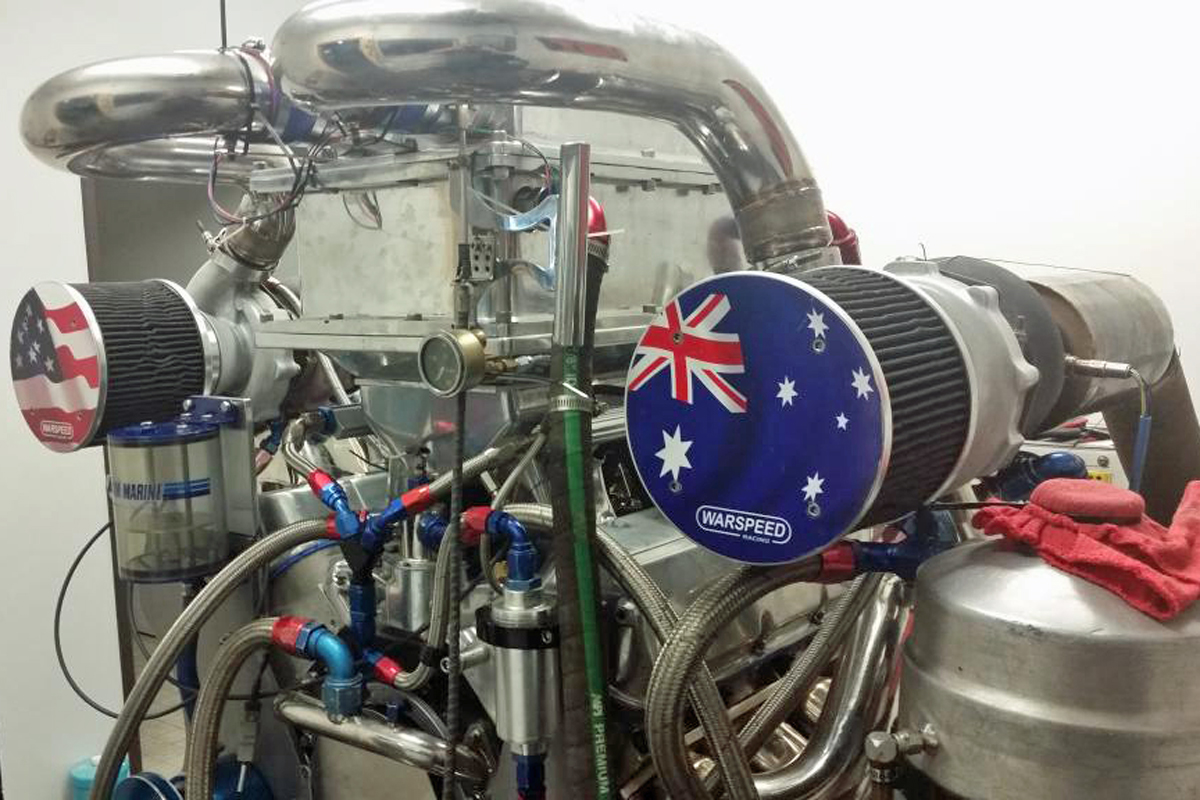

On top, a Dart tunnel ram intake manifold sucks down the 20-plus pounds of boost through a pair of 72mm throttle bodies and a custom Detroit Diesel intercooler. A pair of 62/68 turbochargers are used, with boost controlled by a pair of HKS GT2 wastegates mounted to Custom Marine, Inc. headers.

On the Superflow 901 dynamometer at RPM Performance in Lake Havasu, Arizona, noted tuner Brian Macy of Horsepower Connection worked the laptop controls on the Holley HP engine control unit.

The customer requested a pump gas tune for flexibility reasons. On the pump gas 10 psi tune, the engine turned out 1,358 horsepower, and once they cranked up the boost with the good gas, the engine spun the dyno needle to an outstanding 1,781 hp at 6,000 rpm and 1,720 lb-ft of torque at 4,400 rpm.

Macy explains, “I have to build a conservative base map for us to start with. Once we get a chance to see how far off we are in the fuel ratio, we get to the point where it’s on the rich side for first pull.”

Most importantly, tuning for transition fueling like the boat encounters while in a turn presents larger challenges for Macy.

“They’re in and out of the throttle in those areas when they come into and exit the corners. I’m going through the fuel and timing table to tune as much of the map as possible, so no matter where he is in the throttle we’ve got the right mixture and the best timing. I’m doing it like a street-driven car where we’re going to tune almost all of the cells in the table; as many of them as I can physically get to at the dyno. Once the engine is in the boat, I’ll go out with them and tune it some more to make sure it launches well,” he says.