A key component to producing reliable power is the good ol’ head gasket, a relatively simple part designed with two main criteria in mind. A quality head gasket keeps the combustion pressures inside the cylinder and the coolant flowing in the engine block, along with sealing return oil from the heads to the crankcase and pressurized oil to the valvetrain – without letting any of the above escape externally.

A number of critical factors must be considered when selecting the proper head gasket to suit a specific application, including the type of engine (blown, turbocharged, etc.), the quality of the sealing surface, the engine’s intended use, ultimate sealing capacity, and more. A typical naturally-aspirated race engine producing 1.5 to 2 horsepower per cubic inch will have between 1,000 and 1,200 psi in the combustion chamber. On the flip side, a blown nitromethane engine like those found in Top Fuel and Funny Car can see upwards of 15,000 psi inside the combustion chamber. With requirements like these all over the map in terms of ultimate sealing, choosing the proper product for the application is paramount to success on the street and at the racetrack.

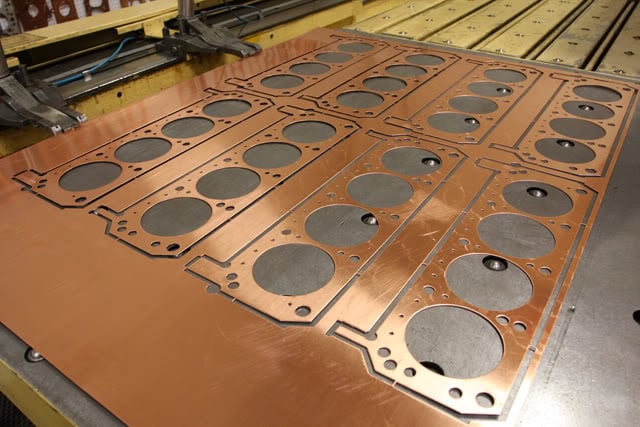

SCE Gaskets manufactures three different types of copper head gaskets – Pro Copper, Titan, and Titan ICS — each one with a different purpose and end use to serve the diverse needs of engine builders.

Why Does Copper Perform?

In head gasket engineering, the very first objective is to trip 60 percent of the total clamp load to the combustion seal. – Ryan Hunter, SCE Gaskets

Copper head gaskets are exceptional in terms of sealing capability for a number of reasons, chief among them is that the metal is malleable and will conform to the sealing surfaces. That conformity allows for a tighter seal, which will result in better performance across the board.

“Higher pressure require a more robust combustion seal, and the best combustion seal is metal-to-metal,” explains SCE president Ryan Hunter, a 25-year veteran of the gasket business. “Many cylinder head gaskets are coated with sealants designed to eliminate fluid leaks. Although those sealants work well for fluid sealing, they are unable to withstand combustion pressure and heat. Once the coating is gone from the fire ring combustion seal, it doesn’t have far to go to reach a coolant passage, and then you have a leak.”

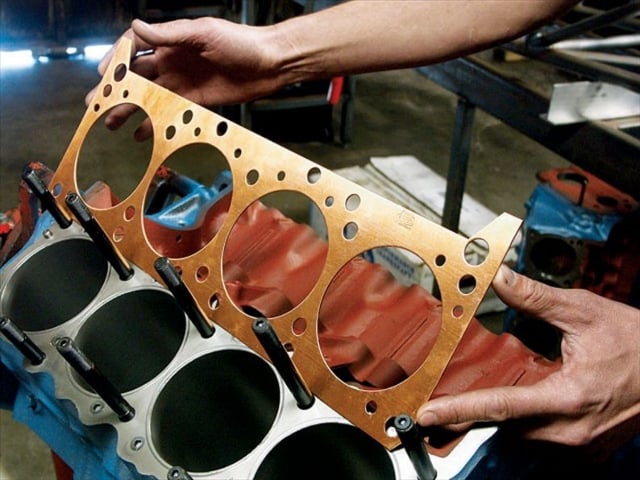

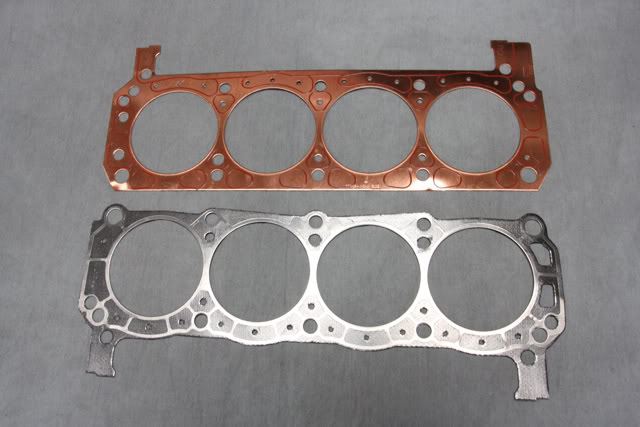

Pro Copper head gasket for Pontiac – note that the gasket is a piece of 99 percent pure copper with no sealing beads on its face or underside. This gasket relies on an o-ring in the cylinder head or block along with a receiver groove to assist in sealing the cylinder’s combustion forces.

A copper gasket also excels in conducting the immense heat imparted to the gasket surface.

This can prevent burned cylinder heads and also permits more even engine-block and cylinder-head temperatures – which aids in tuning consistency.

This can prevent burned cylinder heads and also permits more even engine-block and cylinder-head temperatures – which aids in tuning consistency.

“The big advantage of copper’s conductivity is in the combustion chamber area. In and around the combustion chamber, standard composite head gaskets and MLS head gaskets are somewhat insulated from the cylinder head and block by the facings and coatings respectively. Heat related failures occur more often with composite and MLS head gaskets than with copper because the heat is trapped within the gasket body allowing hot spots to intensify, whereas the copper being both a better conductor and having direct contact with the block and head (remember metal-to-metal) transfers the heat to the heat exchanger – the cooling system – through the head and block,” he explains.

Pro Copper

SCE’s Pro Copper gaskets are recommended for use with extreme boost, nitrous oxide, blown alcohol, or nitromethane-injected engines. These are constructed from 99 percent pure copper sheets that are rolled to your choice of twelve different thicknesses. Prior to the manufacturing process, they are tested for uniform flatness, which ensures head-to-block alignment and eliminates uneven loading. With these gaskets, O-ringing the engine block or cylinder head is required. They also require the use of sealant around the oil and coolant passages to prevent leakage.

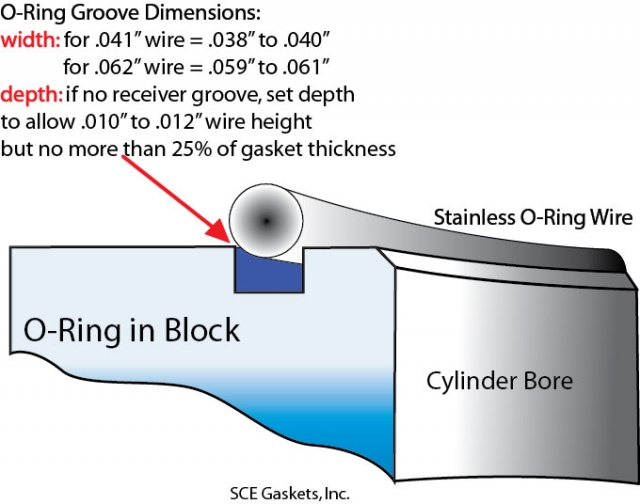

O-ringing with stainless-steel wire is a step that permits much better combustion sealing with the Pro Copper line of head gaskets. It is important to note that when using aluminum cylinder heads to machine the O-ring groove into the head surface and the receiver groove into the engine block to prevent friction brinnelling of the head surface. Friction brinnelling could occur when the O-ring causes a permanent indentation into the cylinder head’s surface due to the heavy clamp load of the cylinder head-to-block connection.

The ring should be set up to protrude from the surface by no more than 25 percent of the gasket thickness. For example, if the gasket being used is .043-inch thick, the ring protrusion height should be .008-inch to .010-inch. This allows the gasket to conform to the O-ring and provide a positive seal, without wrecking the capability of the gasket to seal the coolant pressure.

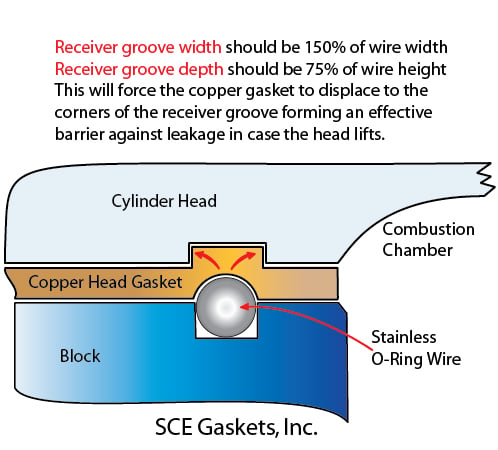

The receiver groove width should be 150 percent of the O-ring wire’s width, while the depth should be 75 percent of the wire height. This forces the gasket to displace to the corners of the receiver groove and form a barrier against leakage should the cylinder head lift.

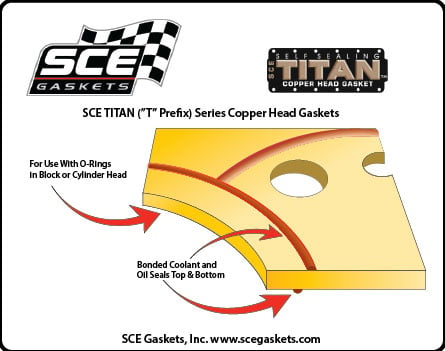

Titan models

The Titan gasket is the next step in the company’s head gasket line. These are self-sealing copper gaskets that have bonded coolant and oil seals on both the top and bottom faces of the gasket surface.

The Titan gasket is the next step in the company’s head gasket line. These are self-sealing copper gaskets that have bonded coolant and oil seals on both the top and bottom faces of the gasket surface.

They are recommended for use in racing engines with heavy boost or nitrous-oxide injection that are running liquid coolant. Like the Pro Copper lineup, they require the use of an O-ring in either the block or cylinder head.

The SCE Titan head gaskets were the first ‘self sealing’ copper head gaskets. Due to the need for clamp load concentration on the combustion seal, the bonded coolant and oil seals are ‘staggered’ top and bottom to allow the malleable copper body to deform around the seals. Hunter was awarded a US Patent for this innovation.

The difference between the Pro Copper and the Titan is in the use of the bonded-rubber oil and coolant seals that allow the end-user to simply install the gasket atop the deck and bolt on the cylinder head. Hunter notes that some builders like to coat the gasket in street-driven applications, and for this the company recommends its Copper Coat [PN G1612].

The same dimensional requirements for O-ring placement and depth that the Pro Copper gaskets use apply with this gasket design. Proper thread sealant must be used if the head bolts protrude into the water jacket to ensure that coolant does not migrate up the threads and leak. Silicone sealer will shear and leak upon bolt retorque.

To Spray Or Not To Spray?

“There are a lot of old guys who say ‘I just know copper gaskets are going to leak so I want to spray ’em with copper-coat’ and to that I say go ahead, it won’t hurt a thing. What will hurt, though, is if too much sealant is used, or if someone uses silicone on the gasket. Silicone is absolutely a bad idea,” says Hunter. There is not a goop on the planet that’s going to seal the combustion pressure. In head gasket engineering, the very first objective is to trip 60 percent of the total clamp load to the combustion seal. We need the load on the combustion seal, not the coolant seal. The gaskets we build are designed in one fashion or another to trip the load to the combustion seal rather than the other seals on the gasket surface.”

Titan ICS gaskets

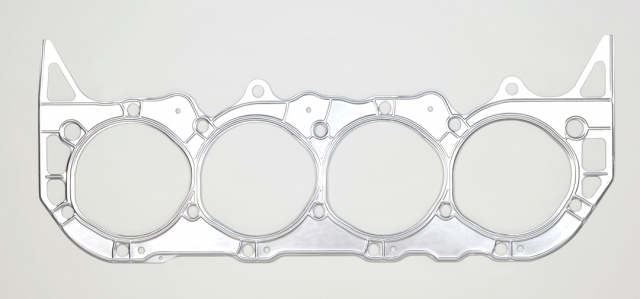

The Titan ICS (Integral Combustion Seal) gasket is the third in the company’s copper gasket line, and the only one that does not require the use of an O-ring in the head or block for sealing assistance. The ICS builds upon the self-sealing bonded rubber coolant seals found in the original Titan gasket line, and adds a built-in steel-wire insert constructed within the gasket body that’s designed to keep the combustion pressures inside the chamber. These are designed for high-performance street and mild race applications where medium boost and nitrous are used.

The integral wire insert performs the same function as the O-ring in the more serious applications, without the hassle of having the block and cylinder head machined to accept the wire ring. The claim to fame for the Titan ICS is “no O-rings, no receiver groves, and no sealant required.”

“Our ICS gaskets do not require any special surface finishes, unlike a multi-layer-steel gasket. The finishes found on new parts out of the box or easily produced by standard machining equipment are well within the preferred range,” says Hunter.

The combustion seal in the ICS gasket uses a unique two-stage dynamic seal. “The first stage of sealing is due to load concentration from the wire inserted into the gasket around the bore. This has much the same effect as installing an o-ring in the block or head, it simply creates a load differential under the tightening head bolts. Secondly, the upper and lower flanges of the ICS remain open to combustion pressure to form a gas seal upon which high pressure gases are allowed to act against the opposing flanges of the seal, forcing the flanges to remain in contact with the sealing surfaces,” he explains.

Other Sealing Solutions

The Pro Seal Composite gasket is designed for high performance street and mild competition, and is built using three pieces – a cold-rolled steel core, pure graphite facing applied to each side, and an extra-thick steel fire ring armor. They are compressible gaskets designed to handle up to 15 pounds of boost or a small shot of nitrous with ease. Any more will require the Titan ICS to properly control combustion gases.

Copper on top, Pro Seal Composite on the bottom. Each has its intended use and will provide excellent sealing capabilities when installed in the proper application.

Going old-school is the job of SCE’s Embossed Steel Shim head gaskets. These are constructed of thin embossed steel to control combustion and fluid, but also permit the racer to increase compression, as in NHRA Stock and Super Stock applications where rules restrict other mods to boost compression.

“We can make these gaskets very thin – down to .015-inch thick. We have the capability to build a very small bore size, and even make it tight to the particular bore opening. What that gives the Super Stock guys, because they don’t have very many ways to increase horsepower, is the ability to gain it back in their mechanical compression ratio,” explains Hunter.

An embossed steel shim gasket is designed for NHRA Stock and Super Stock, where racers are extremely limited in the types of engine modifications they can perform.

Don’t think the company builds only race gaskets. SCE also offer its Engine Master series, a premium OEM-replacement style gasket that meets or exceeds OEM specifications. Although not recommended for racing applications, they are perfect for that minivan engine rebuild or even a stock small-block Chevy.

Expert Testimonials

“The Titan ICS works in applications where a conventional head gasket would not work,” praises Kenny Duttweiler of Duttweiler Performance. “We’ve had good success with them in engines making 1,200 horsepower or so, but above that you need to get into a copper gasket and O-ring. We use the Titan gasket in applications above that where there is water running through the engine; the printed seals do an excellent job of sealing up the engine.”

He has found the break point from a Titan gasket to the Pro Copper gasket is where the engine has a billet head and block and there is no water passing between the two components, since no fluid seals are required.

“As long as there is water going between the block and the head, the seals printed on the Titan work extremely well. Any time where you have elevated cylinder pressures it’s pretty much mandatory that you use an O-ring and a groove with the Pro Copper or Titan gasket. The groove stops the migration of the gasket out of the cylinder where it starts moving away from the bore. By putting the receiver groove into the head, it’s been totally successful for us,” he says.

To put it in perspective, Duttweiler says max-effort engines work best with the O-ring and receiver groove and Pro Copper gaskets, medium effort engines should use the ICS gasket, and wet engines should use the Titan.

In the George Poteet-driven Poteet and Main World’s Fastest Piston-Driven vehicle, Duttweiler uses the Pro Copper gaskets to seal the engine well enough to hit 462 mph at the Bonneville Salt Flats with 347 cubic inches of twin-turbocharged small-block – at 6,000 feet of elevation.

George Poteet Running The Number At Bonneville