Despite all of the “black magic” tricks that have been applied to carburetors over the years, they are still a simple device that has a simple task – provide accurate amounts of air and fuel to an engine in order to facilitate complete combustion of the mixture.

Pro Systems' SV1 (Single Venturi) Carburetor with all of its billet shiny goodness. These are available in a number of different sizes that Pro Systems will recommend depending upon your combination.

There are a number of designs that have been innovated over the years, and the most recent is the SV1 single-venturi carburetor from Patrick James and his Pro Systems custom carburetor company. James, who holds a fluid dynamics engineering degree, noticed a number of issues with the 4150 and 4500-style carburetors that he thought could be corrected by a clean-sheet design, namely the problem of having the center section and air-cleaner stud area disrupting airflow into the carburetor.

James found that “clean air” – the air flowing around the inside of the throttle bores near the center section not carrying fuel into the manifold – was the most important issue that he could cure with his new design. But before we get ahead of ourselves, a bit of background on the downdraft 4150/4500-style carburetor and its inherent issues.

Four-Barrel Shortcomings

The first 4150 carburetor was put into production for the 1957 Ford Thunderbird and the modular design has proven to have great staying power in the drag racing and motorsports marketplace. There are a number of reasons why, but cost and ease-of-use for the average racer are at the top of the list here. However, the carburetor design is not perfect, and often racers can get stuck trying to tune one when they’re not real sure what to change.

Left: In a 4150-style carburetor, the center divider plays a big part in directing airflow into the four smaller venturi. Air does not flow evenly over each booster, nor through each blade - causing tuning issues that can be mystifying at times. Right: James designed the SV1 to use standard Holley service parts including fuel bowls and accelerator pump mechanisms.

As the four-barrel consists of a booster above each throttle blade, one of its inherent issues is that the blade blocks the vacuum signal from the engine from properly enriching the fuel circuit until the blade is completely perpendicular to the bore at wide-open throttle. As we’re sure some of you have encountered (yes, we’re pointing right at you!) the struggle to get idle metering correct on a 4150 isn’t always easy, especially for a novice tuner – big lumpy camshafts and idle quality do not always go hand-in-hand, and many carburetor owners struggle to get a clean “drive-it-anywhere”-style idle from their modified four-barrels.

According to Pro Systems' James, the air drawn in around the center divider is clean air - air with no fuel suspended within, and thus, air that doesn't burn very well.

Why is this, you ask? Well, there are a number of issues with the four-barrel design that can cause idle quality to suffer, especially on an engine that’s been cammed and compressed to within an inch of its life. On a 4150/4500, the front and rear of the blades allow atomization of the idle fuel, but the sides of the blades (inline with the throttle shaft) stay tight to the venturi at all times and act like a divider. In addition, the back side of the throttle blade (opposite the transfer/idle ports) only allows in “clean” air as the fuel can’t get past the throttle shaft (which acts like a drip-rail) to the backside of the blade, ensuring that only the outside edge of each throttle blade are the only places where the fuel is actually entering the carburetor.

Single Venturi Goodness

The SV1 carburetor is designed and manufactured here in the United States by Pro Systems personnel, and in fact was designed in-house by James after hundreds and hundreds of dyno sessions, observations, and plenty of trial-and-error – and a stroke of luck.

The SV1 carburetor is designed and manufactured here in the United States by Pro Systems personnel, and in fact was designed in-house by James after hundreds and hundreds of dyno sessions, observations, and plenty of trial-and-error – and a stroke of luck.

James explains, “I was doing some work for Northrup Grumman designing a nuclear reactor. They have pipes that push hot water to cool the reactors. Anytime that you push hot water past these pipes, it gets turbulent on the back side of the pipe. That in turn costs a lot more money to push that water. In working with them, I patented a deal that allowed air to be sucked in at the back side of the pipe, and what that did is calm the “flopping” down, which helped the pumping efficiency and ended up saving them about $50,000 a month in electricity bills just from calming down that water flow.

When we were working on the patent, I asked them to write it so that I could write the patent for my booster to be able to use it in a carburetor. – Patrick James

By nature of its design, the SV1 carburetor exposes both the front and rear halves of the blade to fuel delivery ports – there is nowhere for “clean” air to sneak by on the SV1. James and his team crafted the SV1 so that there are mixture-screw-controlled atomized fuel ports everywhere that air enters the engine. The Double-Pumper issue of the throttle shaft separating the four-barrel blade in half and affecting idle quality is also gone, as the idle fuel of the SV1 is pulled around the entire perimeter of the large single blade, greatly improving the mixture quality in the idle RPM range. The SV1 works well on nitrous cars for this reason, as the well-mixed air/fuel combination prevents cold nitrous plugs from fouling out due to an improper mixture. This also helps to keep the plugs clean in a real street car, along with working well in a throttle-stop/bracket car.

Left: On an SV1, the entire carburetor acts as one large venturi - there is so much signal that reaction is almost instantaneous. Right: The single-venturi design of the SV1 acts like one huge booster from a four-barrel - taking Bernoulli's Principle to the extreme in the name of going quicker and faster.

One Versus Four

In a traditional 4150/4500-style carburetor, the booster sits directly above the throttle shaft and blade. Throughout all of their testing, the issue that James and company found with this arrangement is that the booster is not able to respond well to changes in air-speed. The SV1-style booster doesn’t rely on the same type of signal-generating center (like an annular/aerosol/dogleg booster), which allows for a cleaner tune. Since the whole length of the booster in an SV1 generates signal, and the blade and shaft are no longer in the way of the signal as with a traditional four-barrel, air-speed changes do not present as large of an issue for the carburetor.

Air-speed changes happen during a number of conditions, most importantly gear-changes and nitrous-oxide engagement, and the SV1 has proven on the dyno and on the track to tolerate these conditions well. By the carburetor responding more quickly to the airspeed variations, you are able to reduce lean spikes and work more on your tuneup, thanks to the new-found air/fuel ratio consistency.

Left: As you can see here, each of the four-barrel's venturi is split in half by the throttle shafts. This affects signal generation as the booster sits right above the shafts on the top side. Middle: The SV1's dual booster tubes actually have four corners of adjustment. Without the center divider in the picture, the signal the carburetor sees is much more robust. Right: Here's an SV1 booster tube. As you can see, it has two distinct sections that do not pass through in the middle. These tubes ride on o-rings to minimize vibration.

What’s the big deal about the “clean” air? Well, clean air is air that does not have fuel atomized within its composition, and air without corresponding fuel enrichment doesn’t have much business being drawn into an internal combustion engine. Over the years, crutching the carburetor tuning along was a necessity, as the carburetor must be kept improperly rich in order to have a good average reading across all cylinders in all conditions.

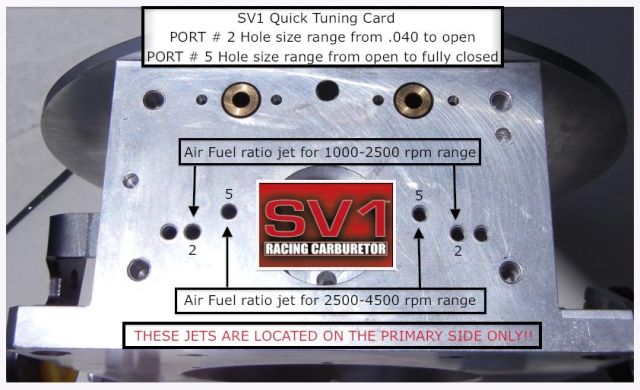

Mid-range tuning is adjusted by changing the jets in the SV1’s primary side. Tuning is accomplished separately for the 1000-2500 RPM range and 2500-4500 RPM area. Chances are that Pro Systems will have a calibration to get you pretty darn close right off the bat.

James, who told us, “Me figuring out the clean air concept was accidental. When I first built one of these to test, I put it onto my 509-cubic-inch engine. I couldn’t believe how well it was idling – I had it set up wrong, and it was idling all the way down at 750 rpm – something it had never been able to do before. I was worried it would stall, but it didn’t. I grabbed a track-temperature infrared gun and shot all of the header pipes and couldn’t believe how even they were – they were always kind of a mess before.”

Continuing James said, “I switched it out to a four-barrel that was too lean, and sprayed the four-barrel with an aerosol pump at the air-cleaner stud, and all of a sudden the cylinder temperatures evened out and the four-barrel came down to idle at 750 rpm also if I kept the mist going. I realized from that quick test that on a four-barrel that the air in the vicinity of the air-cleaner stud wasn’t getting any fuel – only air. The fuel stays on the outside of the blades and not the inside.”

According to James, clean air is the enemy in an engine as it typically stays clean all the way into the cylinder it feeds, preventing proper fuel enrichment and potentially proving harmful to the engine in the process if the condition is severe enough.

The SV1 idles so good because there is no clean-air section; the four feed holes run around the perimeter of the blade. This wasn’t something I had planned on happening – it was just a bonus after the carburetor was already designed.

We asked James to put it in simple terms for us, and he explained, “You can think of how the SV1 works this way. In a standard four-barrel carburetor, the booster only generates signal over the center of the blade. The SV1 acts almost like a vacuum secondary carburetor. Let’s say you’re sitting at a stoplight with the throttle blade closed, you’ve got say, eight inches of vacuum underneath the carburetor. If you jack the throttle to ten percent of throttle angle, instantly air rushes in to fill that vacuum and it starts right at the very edge of the venturi.

“On a four-barrel carburetor,” James continues, “the air rushes over the booster holder, not the booster generation section – it doesn’t prime the booster at all. On an SV1, because the booster generates signal over its whole length, when you jack it to ten percent, the first air that rolls in starts sucking on the metering block right away because it’s right there. As you roll in and out of the throttle the booster increases or lessens its effect.”

The robust design of the SV1 features a pair of billet accelerator pump arms to resist flex.

Consistency

The Pro Systems motto over the years has been “Racing and High Performance…it’s all we do.” Racers like Tony Bischoff of Bischoff Engine Service, Billy Glidden, Reher Morrison, and many more work regularly with Pro Systems carburetors both in their own racing programs and for their customers. By specializing in this market, the company has been able to work hand-in-hand with its customers to provide them with a true custom-built, custom-engineered product for their requirements. The SV1 is no doubt one of the wildest iterations we have seen from the 4150 style carburetor that we look forward to seeing racers utilize to go faster in years to come.