“Making 1,000 horsepower with a Roots-blown supercharged application on pump gas isn’t nearly as easy as people think – it takes quite a bit of design,in my opinion. Most of these guys that talk about 1,000 horsepower with a Roots supercharger aren’t really doing it,” says Hilborn Injection‘s Andy Starr. “This thing was spectacular on the dyno. It fired right up and was ready to run, and that’s one of the advantages to working with a pro like Andy Jensen.”

Starr collaborated with noted engine builder Andy Jensen of Jensen’s Engine Tech and customer Chuck Marsh to build and tune this 555 cubic inch blown pump gas big block Chevrolet engine, complete with 14-71 Mooneyham supercharger, to achieve that mythical thousand-horse number. Monty Davenport at Mooneyham was responsible for tuning up and re-stripping the supercharger prior to the engine build, and also installing a pair of fuel injectors into the back of the blower. More on those later.

So far, Chuck Marsh has the engine installed into the frame; he’s still working out the details of the rest of the build and is shooting for the Big Tire Power Adder class in Drag Week if all of his plans can come together.

One of the group’s goals during the design and construction process of the engine build was to keep the engine’s intake air temperatures as low as possible. The Roots supercharger design is well-known for presenting extremely high intake temperatures; as the air is compressed inside the supercharger case, it picks up a lot of heat, and that’s where the Hilborn EFI design came into the picture.

“I was the guy charged with putting the fuel to the combination. When Andy told me they were going to use the 14-71, I knew we were going to be able to make the power, so we went ahead and upgraded to a larger injector to be able to provide the fuel that Chuck needed,” says Starr. “I’m tickled to death with how well the Weldon and Holley products work – they do what they are supposed to every time.”

Starr spec’d the Hilborn EFI system with an Enderle Bug Catcher hat atop the supercharger, an 8 nozzle plate from Hilborn, two additional injectors installed into the back of the blower case, a Weldon Racing DB2025A fuel pump and matching regulator, and one of Holley‘s HP ECU units to control it all.

The injector plate is sandwiched between the blower and the hat, with eight injectors placed into the plate and supplied fuel through a -8AN fuel rail on each side. By putting the injectors atop the supercharger, they help to keep the aforementioned high inlet air temperatures within a reasonable range.

“The more inlet air temperature we have, the less efficient the engine is going to be. High temperatures also unsettle the engine and make it more prone to preignition or detonation; whatever we can do to calm down those inlet temperature, we can make more power and help the engine to be more stable,” says Starr.

One of the interesting things to note about this particular build are the aforementioned supplemental injectors placed at the rear of the supercharger case to assist in fueling.

“The decision to use the 14-71 was based on the fact that by keeping the rotor speed down, we will reduce inlet air temps compared to making the same boost by spinning a smaller supercharger faster. With the case of the 14-71 being so long, parts of the rotors were positioned too far from the fuel supply warranting the two supplemental injectors in order to reduce air temps in the blower,” explains Starr. “Gasoline as a whole is really bad at keeping inlet air temps down unlike fuels such as E85 and alcohol. One can even supplement with a water/meth kit or nitrous to substantially reduce inlet air temps under boost if necessary.”

Four injectors in each side, and two in the rear provide enough fuel to keep the engine happy and air inlet temperatures down.

Starr mentions that although one might think a Roots supercharger does a good job of mixing the air and fuel components on their way through the blower case, that’s often not true – some superchargers run lean in the front and rich in the back, and for others the opposite is true in his experience, thus the use of the supplemental injectors. They use a pair of wideband oxygen sensors in this application to gather data, one in each collector.

“Unless you run individual oxygen sensors or even EGT’s in each cylinder, you’d never know it, and that’s not practical in an application like this. Instead, you run the engine inherently fat so that we can get the averages where we need to be, and find a happy medium,” says Starr.

Jensen concurs. “You can’t tune each cylinder with the injectors above the rotors in a supercharged application like this, so you have to look for an average number. If the injectors were in the runners you’d be able to tune each cylinder, but with the injectors above the rotor, there’s no need to monitor the individual cylinder, so we just shoot for a good average number and making it safe,” he explains.

The 555-cube engine consists of a World Products Merlin block, Callies forged crankshaft, Crower connecting rods, and JE forged 2618 forged pistons. There’s also a hefty custom-ground solid roller camshaft from COMP Cams, Crower lifters, and a set of Brodix‘s finest BB-3 XTRA Series 24-degree conventional-style cylinder heads on top, which Jensen says is an excellent fit in this application.

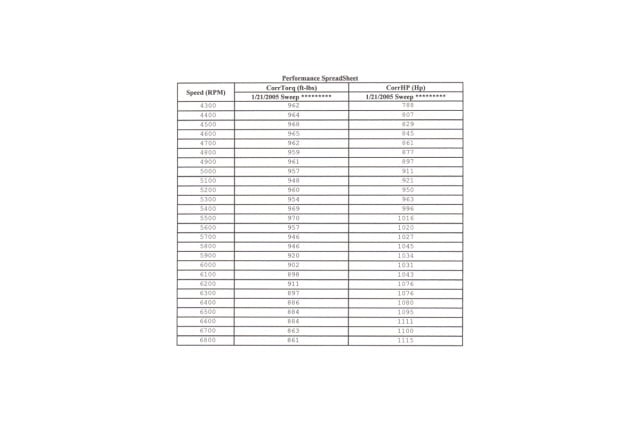

“You have to be cautious with your duration and overlap numbers when designing the camshaft. You also have to take the electronic fuel injection into account. There are some things you need to be careful of, but a forced induction engine this size with a supercharger this large, it’s pretty easy to make a lot of power. We weren’t pushing it at all, and it made 1,115 horsepower on race fuel with 14 psi boost pressure,” says Jensen.

Left - Another view of the injector plate underneath the hat. Right - The engine awaiting assembly of the rest of the car around it.

He feels that the engine is capable of even more power with more boost, but the customer’s requirements had him setting the engine at 7 psi to keep the engine drivable on the street with 93 octane pump fuel, which is where it cracked the 1,000 horsepower mark.

Machining processes are straightforward as well. “You have to make sure you have good, straight, round cylinders so it seals up and holds the power, and good clearances with a good supply of good oil,” Jensen explains.

He shoots for .0036-inch to .004-inch oil clearance on the main bearings, and between .0028-.0032-inch oil clearance on the connecting rods for proper oiling.

“It was a pleasure to work with Chuck and Andy Starr. We had good quality people on the project all around and it worked out to be a great job,” says Jensen.

Marsh agrees. “Originally I was just looking for a set of heads, but after talking with Andy Jensen we decided to take this project to the next step. Andy’s a real knowledgeable guy, and we came out with exactly what I wanted to build.