One of the core components of any engine — whether OEM or high-performance — is the crankshaft torsional vibration damper. Sometimes called a harmonic balancer, or simplified to just “balancer” or “damper” this component performs a thankless job in the engine, that you really can’t see unless you have the engine hooked to an advanced sensor suite.

ATI Performance Products has been making high-performance Super Damper harmonic dampers for a long time. Besides being SFI 18.1 approved for competition use, there is over three decades of research and development in each of ATI’s Super Dampers. As you might expect, the catalog of applications supported by ATI is quite large, but what if you have an application that isn’t supported?

That’s where ATI’s custom capabilities come into play. Knowing that they can’t have applications for everything, they have a system in place to create custom and semi-custom dampers based on an individual customer’s needs. “It all starts with the custom damper worksheet,” says ATI Performance Products President, JC Beattie, Jr.

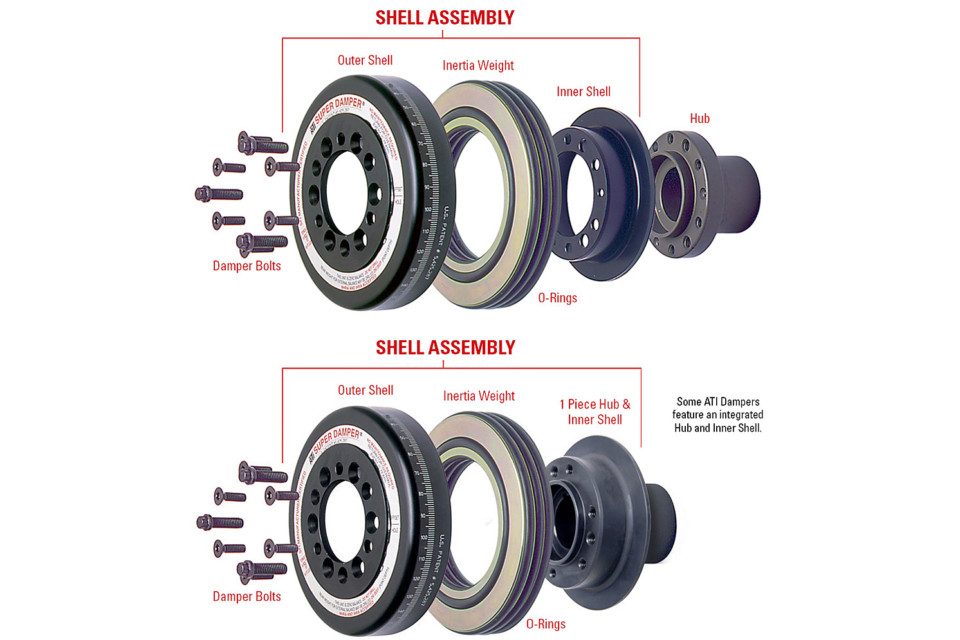

ATI’s Super Damper is a complex piece of equipment, which is specifically designed for each individual application. By knowing key specifications about an engine, the damper portion can be custom designed for a specific application.

Building Something New

While building a custom damper is more than just fitment measurements those measurements are critical. “First and foremost are space constraints on top of the other info we look for,” explains Beattie.

The basic physical measurements of the crankshaft snout and location, size of any keyways, desired hub bolt pattern and required accessory drives on the balancer are all laid out. These provide the proper physical fit of the damper to the crankshaft.

That’s the easy part. The difficult part involves variables such as the number of cylinders, engine displacement, power, maximum RPM, crankshaft weight, and even time between rebuilds. These factors are all taken into consideration when creating the actual torsional damper portion of the unit with ATI’s dual-elastomer design.

Besides designing custom harmonic dampers, ATI’s custom shop also offers a rebuild service for existing dampers, where an ATI Super Damper is torn down to its component parts, cleaned, and reassembled with new hardware and components as needed.

“We don’t have any program that we plug all that information into, it’s all good old-fashioned know-how,” Beattie says. “It comes from 31 years of making high-performance dampera, and 25 years of torsional vibration knowledge personally gained by testing.

In all those years of testing, Beattie has come to be able to size up a new damper’s need pretty quickly. “The easiest motors to design a damper for are well built, fully center-counterweighted, conventional small-block and big-block V8s that are modest in their horsepower and RPM for their build specs,” he says. “The most difficult are high-revving high-horsepower four-cylinder engines.”

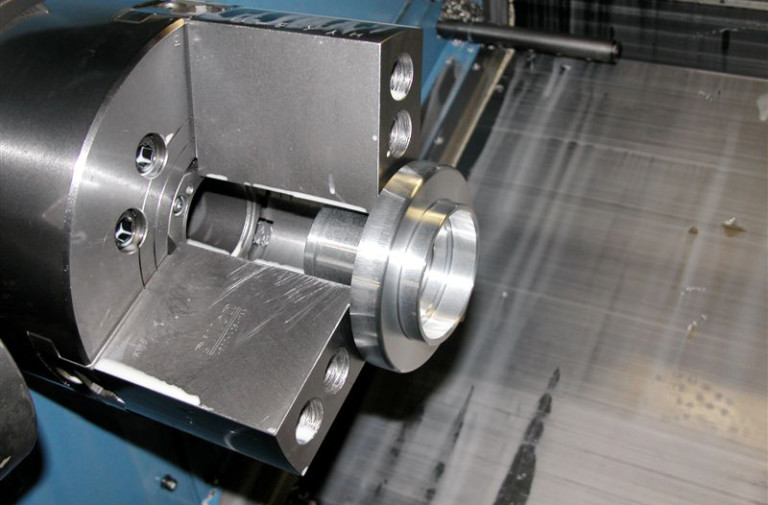

In addition to designing the correct torsional damper section of a custom Super Damper, the hub has to be machined to exacting specs. Custom hubs can be one of the more complex aspects of designing a custom Super Damper.

Modern Engines Changing Things Up

Sometimes, it’s not a one-off custom engine that presents the largest challenge, but rather a new, modern engine design, that does things differently, which proves to be a challenge. “The new BMW/Supra damper is an oddball, so for something like that, we get a sample damper to work with,” Beattie says.

One of the unique features of the B58 engine design, is the use of a crankshaft without a snout. While this poses a slight challenge, it’s not an insurmountable one. “[The lack of a crank snout] doesn’t help in our opinion, but providing there is plenty of clamping force, such as the 4 big bolts used on the damper, it’s okay,” says Beattie. “[The four bolt crank attachment] comes from the factory that way and we are not going to re-invent BMW’s doing. We also make the hub and timing gear drive part into a one-piece assembly for extreme applications, which is standard on BMW, Audi, and VW snouts.”

For some applications, like many European engines which don’t use a traditional crank snout and single bolt arrangement, the hub and inner-shell are integrated into a one-piece assembly.

Other than the lack of a snout the B58 damper presents other challenges. “As with all BMW dampers, they are very thin,” reveals Beattie. “It doesn’t give us much room to get one of our dampers on it and hold OEM spacing. So, we have to figure out home much there is behind the damper that we can encroach on, or if there is any room in front of the damper as well.”

While the OEM damper may be thin, for the ATI Super Damper to do its job properly, it needs to be deeper than the OEM BMW damper. “A Damper needs mass. Without it, the damper can’t do its job,” says Beattie. “We would rather not build a damper at all, than build one that will not be the best we can build.”

While ATI does have an incredibly large catalog of applications, there are still many more to go, be they high-performance custom performance efforts, or simply new applications coming to the market. With both their custom and R&D sections running hard, there is no application they can’t take on.

In the end, whether it’s a custom application or just a new one, the ATI engineering team will put together a product that performs as advertised by leaning on thirty-plus years of harmonic balancer manufacturing experience.