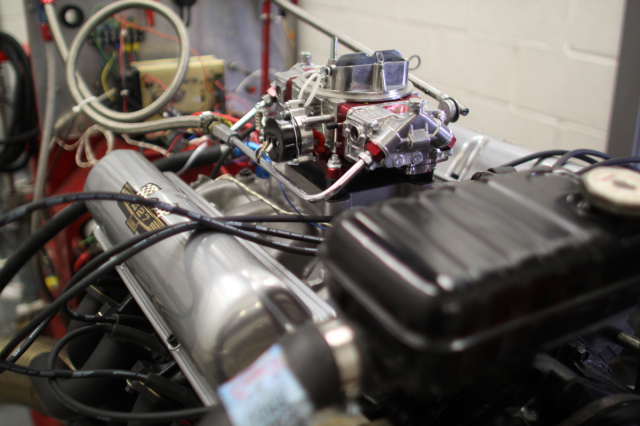

These days, the Ford FE engine doesn’t get much love; it’s been out of production since 1976. Mike Curcio Race Products just put one together for a customer to use in his 1964 four-speed Galaxie, and was kind enough to invite EngineLabs up to check out the engine’s very first dyno session.

“He approached us with the intention of building a solid street engine, we think we achieved that goal,” says Curcio.

The engine is based around a 427 marine block, which was machined to end up with a 4.255-inch bore dimension. The 427 had the benefit of a forged crankshaft from the factory; this was re-used in the build along with a set of stock forged 427 connecting rods that have been upgraded with ARP bolts. In the interest of remaining street-friendly, Curcio specified a set of custom Diamond pistons to use a low-friction ring pack and 10.1:1 compression – pump fuel is the order of the day on this build.

Rather than upgrade the engine to modern specs, the customer who owns the engine wanted to keep the solid flat tappet camshaft design Ford originally specified, so a custom grind was developed to take advantage of the medium-riser cylinder heads used in the build.

The heads feature modifications designed to promote longevity and better performance without breaking the bank, owing to the engine’s street roots. MCRP’s business has long been centered around induction development, and in this instance Curcio put his knowledge base to work and machined the heads to use larger-stem valves. The factory valves use 3/8-inch stems, but these heads now have 11/32-inch valves to go with the new bronze guides. Hardened exhaust seats were also put in place to better handle the demands of today’s pump fuels.

“On the intake side, we used a 45 degree seat angle with four angles total, and a 45 degree angle on the exhaust with a radius seat. The stock angle is 30 degrees, intended for low-lift airflow. The move to 45-degree seat profiles is aimed more at mid-lift airflow; more modern cam lobe profiles don’t need to rely on low-lift airflow to make power,” says Curcio.

Manley Performance valve springs, retainers, and locks were used, and Curcio didn’t perform any port work other than blending the valve job into the ports as it wasn’t required in this application. The use of 2.10-inch intake valves and 1.60-inch valves helped to build power without porting the heads; Curcio says the medium-riser heads are big enough for this engine, and he enlarged the valve sizes to take advantage of the flow capabilities that are already there.

Modifications to the intake manifold centered around improving flow and port entry into the cylinder heads.

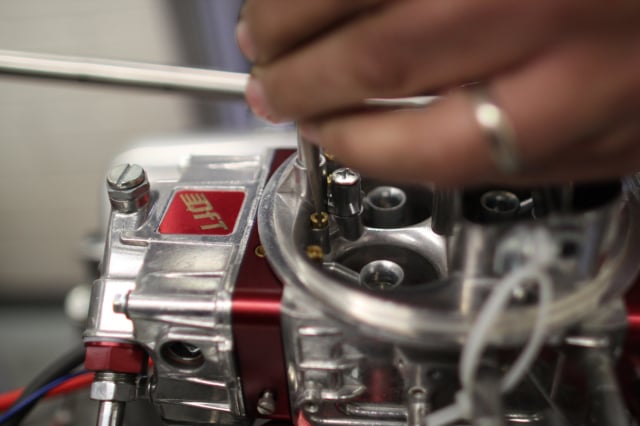

The rest of the induction package centers around a vintage Offenhauser intake that received Curcio’s custom touches in the plenum to optimize performance and was subsequently port-matched to the cylinder heads. A Quick Fuel carburetor sits on top.

During our time at the shop, Curcio made approximately ten pulls on the dyno, breaking in the engine and checking the specifics like oil pressure, how the engine responded to different ramp rates, and most importantly, brake specific fuel consumption. The latter measurement led him to change out the air bleeds in an attempt to lean out the engine, and it worked flawlessly – the engine responded and was very repeatable within one or two horsepower. The best pull of the day resulted in 451.6 horsepower at 5,400 rpm and 481.9 lb-ft of torque at a low 4,300 rpm – perfect for the street.

Curcio says they’ll be making a few more pulls over the next few days, and he expects to see an improvement over the numbers we witnessed, somewhere on the order of 15 additional horsepower as the rings seat in and he has a bit more time to finalize the nuances of the carburetor’s tuning.

A sweet build, and a great day on the dyno with a fun engine!