It’s not often you see a 1000-horsepower four-cylinder engine, let alone, get to see inside of a 1000-horswpower four-cylinder engine. Stephan Papadakis, a long-time sport compact driver and really, pioneer, walks us through as he tears down the engine from the Papadakis Racing Formula DRIFT 2019 Toyota Corolla, giving the viewers an inside look at what goes into such a powerful, compact turbocharged engine.

The engine is a Toyota 2AR-FE inline-four, which, in its stock 2.5-liter form, powers the RAV 4 and Camry with a 6,200-rpm rev limit. This version has been stroked to achieve 2.7 liters of displacement, drinks ethanol fuel, and gets force-fed atmosphere from a 68mm Borg-Warner EFR 9174 turbocharger and 150-horsepower worth of nitrous oxide, while spinning up to 9,000 rpm, “all day long” per Papadakis. Unlike drag racing or road racing where the engine is usually accelerating or decelerating, a drift engine usually spends most of it’s life at or near it’s maximum RPM, due to the nature of the sport. No one would ever accuse drifters of “babying” their engines.

The 2AR-FE engine utilizes this unique camshaft cage/girdle, which secures the camshafts independently of the cylinder head. Papadakis says this setup is very stiff, and we can see the benefit of not having to machine or replace the whole cylinder head in the event of a camshaft failure.

As Papadakis starts removing the fuel rail, the massive 2000cc/minute (190.5 lb/hr) fuel injectors–mounted in adapter fittings–are revealed and removed. The four individual ignition coils are removed, prior to removing the OEM valvecover. The reason we point out that the valvecover is OEM, is because of the intricate oil sprayer system in it, which sprays oil onto the camshafts to keep the cams and valvetrain both cool as well as lubricated.

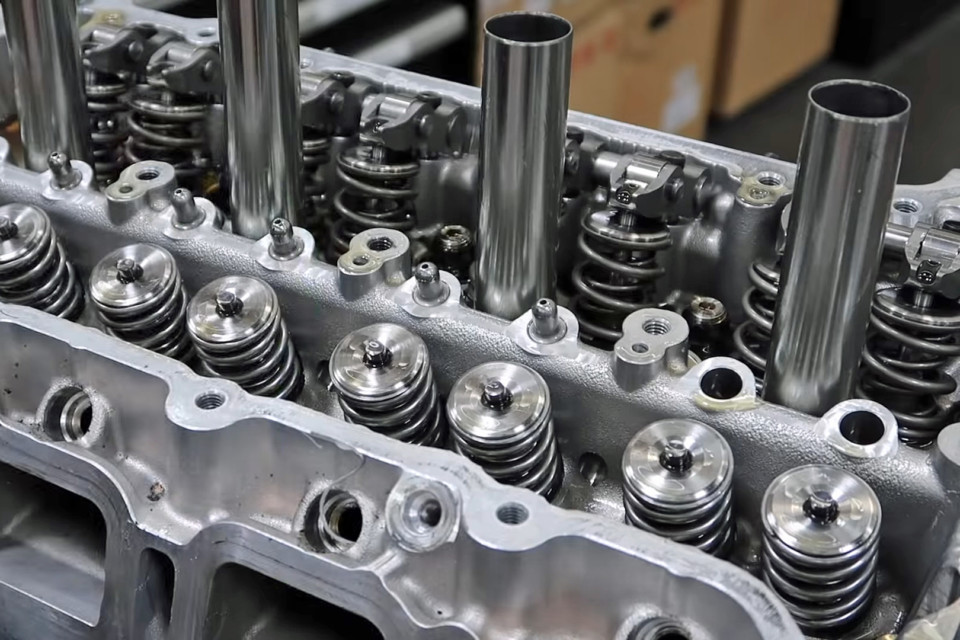

With the valvecover removed, you can see the engine’s completely custom lightweight valvetrain, which is in stark contrast to the next component removed – the OEM water pump. Back to the aftermarket components, Papadakis removes the safety lock wire in the bolts before removing the multi-stage dry-sump oil pump assembly.

Then, Papadakis uses a chain wrench and two-foot breaker bar to remove the crank pulley bolt, which is held in with 192 lb-ft of torque, before tossing a pulley puller on to remove the crankshaft pulley. Then, he pops off the tall timing cover, to reveal the adjustable timing gears and what seems like a nine-foot-long timing chain (eat your heart out, Ford Four-Valve Modular).

While there are some surprising OEM parts used in this engine build, they aren’t in the valvetrain. Titanium is used wherever possible, and a custom shaft rocker system, along with custom solid lifters are utilized for maximum durability under 9,000-rpm engine speeds.

Interestingly enough, the camshafts come out of the engine as an entire assembly, using a unique “girdle” unit, which adds rigidity, per Papadakis. Then, we see the aftermarket solid lifters which replaced the OEM hydraulic units, and the shims used to adjust the valves, as he removes the custom shaft rocker setup from the cylinder head.

Next comes the cylinder head itself, with its oversized 1/2-inch head studs requiring 150 lb-ft. of torque to remove, revealing the four 90mm cylinders and pistons, along with the multi-layered steel head gasket. Papadakis points out the presence of rust on the deck and in the cylinders, as they use straight distilled water in the engine, and even in only four race weekends, the red menace forms.

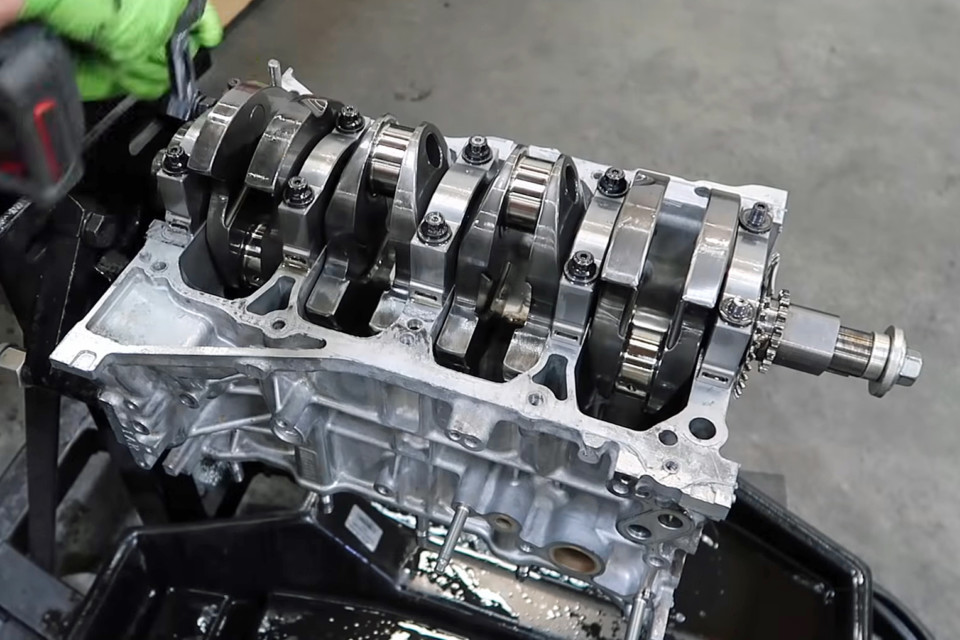

Then Papadakis moves to the bottom of the block to remove the completely custom billet dry-sump oil pan and remaining oil-pump hardware. One removed, we get a peek inside and can see the four internal scavenge areas, along with the first glimpse of the rotating assembly.

Both for robustness and because of the relatively specialty application, Papadakis went with a billet crankshaft from Bryant Racing. While it comes in at seven pounds more than the cast OEM piece, the additional strength the extra mass provides, far outweighs any of the downsides.

As he starts to disassemble the rotating assembly, we see that the rod bearings are in surprisingly good shape after four race-weekends. Then we see the forged H-beam Carrillo rods and the custom forged 2618 JE pistons come out of the engine to be cleaned and reused.

Then we come to the crown jewel of the rotating assembly, the custom billet Bryant Racing crankshaft, which is held in place with billet steel main caps. Seven pounds heavier than the OEM crankshaft, the Bryant billet piece is built like a tank to easily live at the 1000-horsepower level.

The main bearings are OEM coated units, surprisingly, and they, like the rod bearings, show no adverse signs of wear when removed. With all the main bearings removed the engine has been completely stripped, and Papadakis can kick back and have a beer, while watching drifting videos–for professional research purposes, of course.