With the final episode of Horsepower Wars LS vs. Coyote 3 aired, everyone now knows that the Coyote came out on top by a scant 19 horsepower, in an amazing 1,400-plus-horsepower shootout. However, one thing was clear with both entrants — the turbo was too small. Now, that’s an easy thing to say with the benefit of hindsight, but in order to be able to really understand what happened, we need to dive deeper into turbo technology to explain what happened.

Really, the turbo made exactly what we wanted it to make, but it wasn’t happy in doing so. So, let’s get into what went sideways. To do that, we’re going to have to start with some basic turbo knowledge.

HPT Turbo Size Definitions

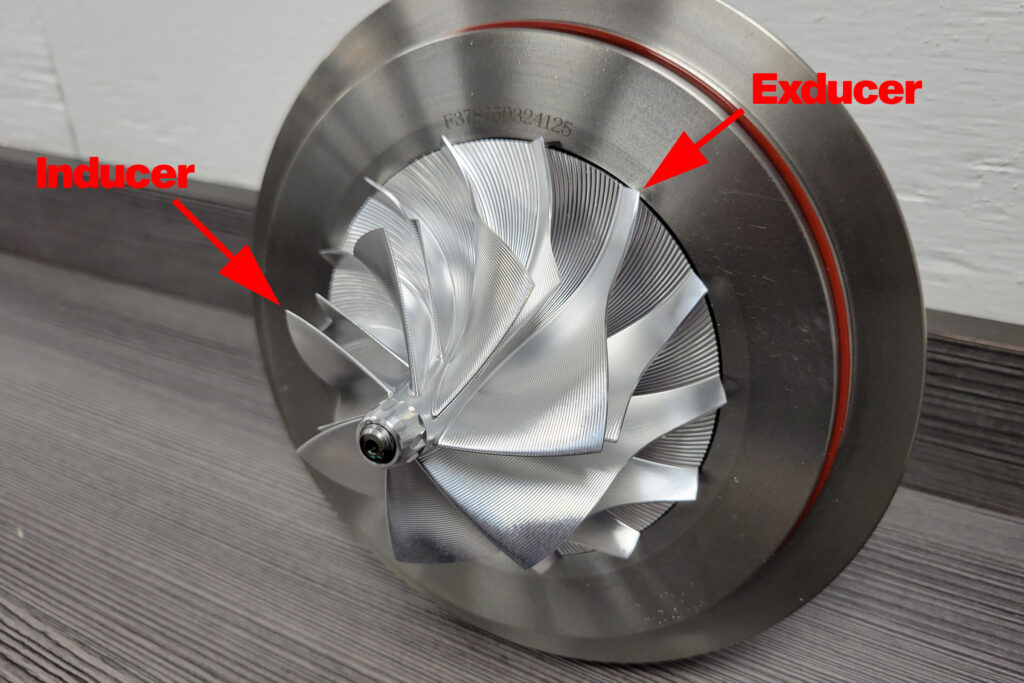

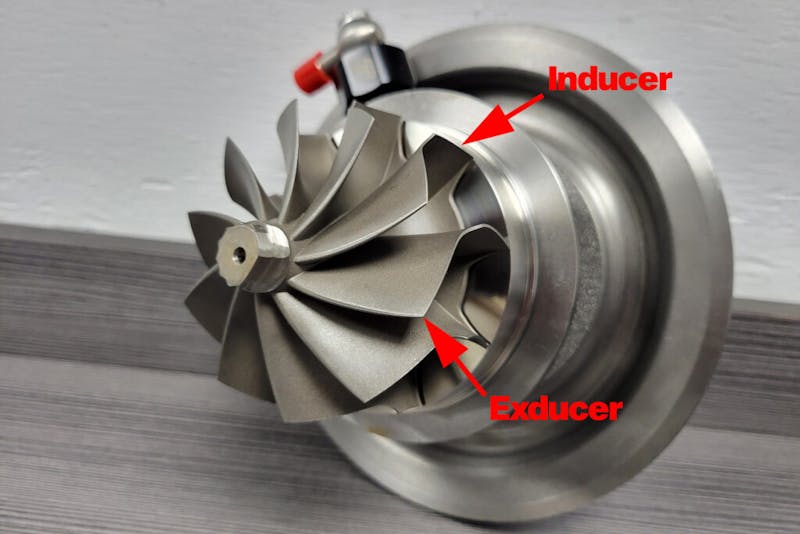

When you describe the turbocharger we used, you’ll usually hear it called a 76mm turbo most often. A more precise name would be a “7680” turbo. Even more accurate than that would be calling it an F3 (HPT Turbo’s nomenclature for a mid-frame T4-sized turbocharger). What do all those different numbers mean? Well, let’s break it down. When we refer to the size of the turbocharger in millimeters, we’re usually describing the size of the impeller of the compressor wheel. The compressor wheel is the cold side of the turbo that takes in fresh air. The first part of the compressor wheel to be touched by air is the inducer, and the last part to be touched as it is flung into the volute is the exducer.

The turbine wheel is on the hot side, and is driven by exhaust gasses. The first part of the turbine wheel to be touched is the larger part of the wheel (unlike the compressor wheel, where it’s reversed), therefore that is the turbine inducer, and the smaller tip of the turbine wheel is the last part that the exhaust touches, making it the exducer. This is important, because when we refer to a turbo as a 7680, that is a “76mm turbo” with a turbine wheel that measures 80mm at the exducer.

Now, the frame size is important because you can have turbochargers with the same (or similar) inducer sizes, that are actually drastically different in sizes. A larger housing allows for a larger exducer diameter, making a larger wheel overall (even with the same inducer diameter), which will move more air. That will be important later in the article.

A/R Ratio Explained

For our competition, both teams ran identical F3 7680 turbos, with a 1.24 A/R. Wait, there’s another number? The A/R ratio is the cross-sectional area of the exhaust housing’s inlet, divided by the radius from that point to the centroid (the geometric center) of the turbine housing. It is a number aimed at telling you how large or small an exhaust housing is for a given turbine size.

There were two A/R options available for the HPT F3 7680: 0.96 and 1.24. The 0.96 turbine housing would be considered the smaller of the two options. It would provide a quicker spool up time due to its lower volume, but would also max out sooner, because it won’t flow as much peak exhaust volume. The 1.24 A/R housing, comparatively, would take longer to spool the turbo to peak boost, but also have a higher peak flow capability, thanks to the larger housing.

The only difference in the teams’ turbocharger was the exhaust flange shape. LME’s turbocharger had a standard T-4 rectangular four-bolt flange, while FFRE opted for the 3-inch V-band inlet. While the two flanges have a difference in area of about 1.07 square inches, any performance advantage is theoretically debatable.

Since the 76mm compressor and 80mm turbine combination isn’t an off-the-shelf configuration from HPT, there isn’t any hard data on the turbo’s performance capabilities, but with a little bit of scientific guessing, we were able to take the rating of the F3 7675 (1,350 horspower) and the F3 7880 (1,425 horsepower), and predict we’d get 1,400 horsepower from the 7680.

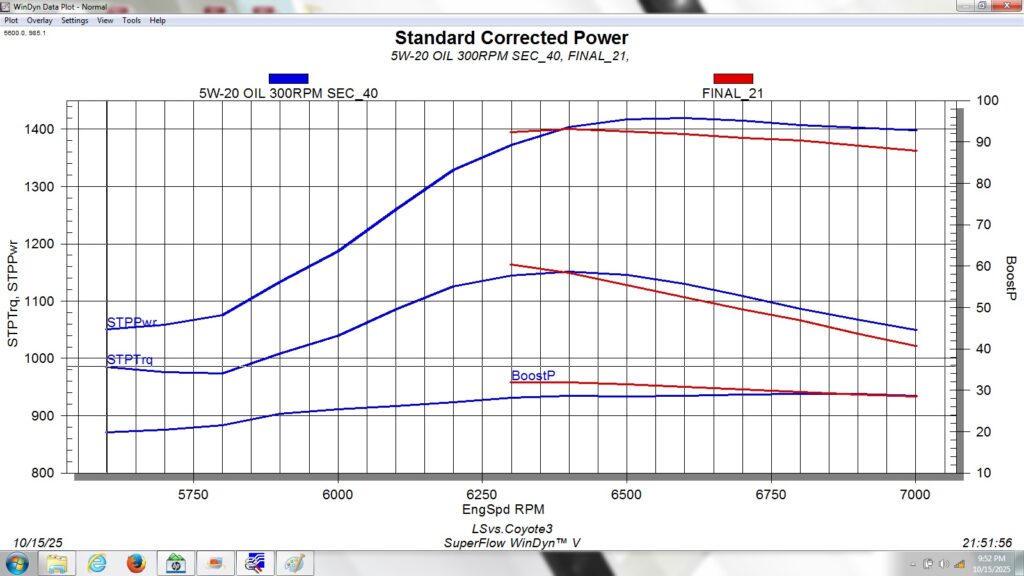

The Dyno Results

Both engines proved our Scientific Wil A$$ Guess (SWAG) correct on the dyno, with both engines making in the neighborhood of 1,400 horsepower. However, what none of us expected was the F3 80mm 1.24 A/R exhaust side to be so much of a restriction. The 80mm exhaust is the largest turbine offered in the F3 lineup, and it being too small is why we didn’t see either of the engines reach their maximum RPM on the dyno.

They were making peak boost much earlier than expected, leading to an Ouroborian cycle of more boost making more exhaust, further exacerbating the problem of choking out the exhaust side of the turbo. When you introduce more exhaust flow than the turbine section can handle, it has nowhere to go and backs up. That creates backpressure between the exhaust port of the cylinder and the inlet of the turbo. In our case, we were seeing in the 90-plus-psi range (3:1 pressure ratio) on the turbine side of both combinations. So saying “the turbo was too small” is only half correct; the compressor side was sized perfectly for what we wanted the engines to make. The exhaust side, however, was indeed way too small.

Bigger Turbos For The Trucks?

A solution was needed, because it was obvious that there was no way the 7680s were going to be happy attached to the engines in the trucks. After a conversation with HPT Turbo, we realized our only option was to move to the large frame turbo, if we wanted a larger exhaust housing. That would be HPT’s “F5” series of turbochargers, which are equivalent to “T-6” turbos. However, off the shelf, the smallest F5 turbo made by HPT is an 80/103 – that is an 80mm compressor and a 103mm turbine, capable of supporting up to 1,800 horsepower.

Our goal for the trucks is to reduce the exhaust restrictions and let them exhale better, not necessarily to make more power. What HPT was able to do for us is something somewhat common in class racing, and that is to take an 80mm compressor wheel, and “cut it down” to a 76mm wheel. While an 80mm F5 compressor wheel cut down to a 76mm compressor wheel moves more air than an unmodified 76mm F3 compressor wheel, we expect the power gains to be in the 100- to 200-horsepower range.

Moving to the exhaust side, HPT recommended we run the 103mm turbine unmodified along with the “smallest” turbine housing: a 1.12 A/R T6-flange model. While significantly larger than the F3 80mm housing, this extra volume will come with the tradeoff of a slower spool time. Realistically, we expect to see much more balanced power and boost curves from this combination.

Unfortunately, we won’t be able to put these new combinations back onto the engine dyno to see what the new turbos do. But they will be going head to head on the dragstrip, and that will be a solid head-to-head comparison of the new combinations, especially since they will now be able to use all of the tachometer. Make sure to stay tuned over on Dragzine’s YouTube channel, because these new turbochargers should absolutely rip.

You might also like

The Cat's Meow: ARP's Cat Paw Washer Stops Overtorquing

Properly torquing your cylinder head fasteners is a critical step, which is why ARP designed the Cat Paw washer.