For best performance, tuning of a racing engine involves fuel mixture control due to atmospheric air density changes and engine setup changes. Sometimes fuel mixture control is done based on record-keeping of past runs or by trial-and-error. In these cases, the goal is to reproduce a tune-up that was used successfully under similar weather and location conditions.

A more precise way to tune is either by measuring and controlling air/fuel ratio (AFR) or by measuring and controlling lambda. This is how electronic fuel injection (EFI) tuning works. Racing mechanical fuel injection tuning and carburetor tuning can work that way also.

AFR Control

Air/Fuel Ratio (AFR) tuning is a form of engine tuning based on the weight of air and the weight of fuel. Different fuels have different weights and work best at different air/fuel ratios.

The stoichiometric point is the AFR where all of the oxygen in the air burns with all of the fuel. At the stoichiometric ratio, only burnt exhaust byproducts are in the exhaust gas mix with no excess, unconsumed oxygen or fuel. Different fuels have different chemical makeups, and thereby different stoichiometric ratios. Using methanol as an example, the stoichiometric AFR is approximately 6.5 to 1. That is, 6.5 pounds of air to one pound of fuel.

In racing, however, running a rich methanol mixture instead of a stoichiometric mixture is routine for the additional engine cooling and accelerator pump shot for throttle response. In high-compression engines or engines with forced-induction, rich mixtures cool the cylinder contents and help avoid detonation. Typically, a rich methanol AFR is around 5 to 1 for a high-compression naturally aspirated racing engine with mechanical fuel injection (MFI).

The amount of enrichment is important for tuning. If it is too little, the engine will run too hot or detonate. If it is too rich, power will be reduced. An easy way to determine the amount of enrichment required, from the AFR is as follows:

Amount of fuel plus enrichment = stoichiometric AFR / actual AFR

Using a typical engine running on methanol:

Amount of fuel plus enrichment = (6.5:1) / (5:1) = 1.3

A result of 1.3 equals 130-percent. This translates to a mixture that is 30-percent rich.

The amount of fuel plus enrichment is also called the “EQ ratio” in some EFI circles.

Low-end AFRs and high-end AFRs present another level of control over the engine tuneup. Optimum AFR combinations for long courses are different than those for short courses. Shorter courses can be run with low-end AFRs that are richer for response. Longer courses can be run with high-end AFRs that are less rich for more power. Optimum AFRs for dirt track are different than those for pavement. Optimum AFRs for a 360 cubic-inch engine are different than those for a 410 cubic-inch restrictor-plate setup that may run the same class. A lot of circle track tuning does not take advantage of that.

AFR and Supercharged Racing Engines

For engines with a supercharger, the AFR is typically richer than in naturally aspirated engines. In another example, a well-developed blown alcohol Hemi V8 racing engine determined their optimum AFR to be 3.4 to 1 or about 91-percent rich. A Hemi usually runs with a richer mixture than a conventional-headed small-block. The optimum AFR for this Hemi was determined as follows:

Amount of fuel plus enrichment = (6.5:1) / (3.4:1) = 1.91 or 91-percent rich

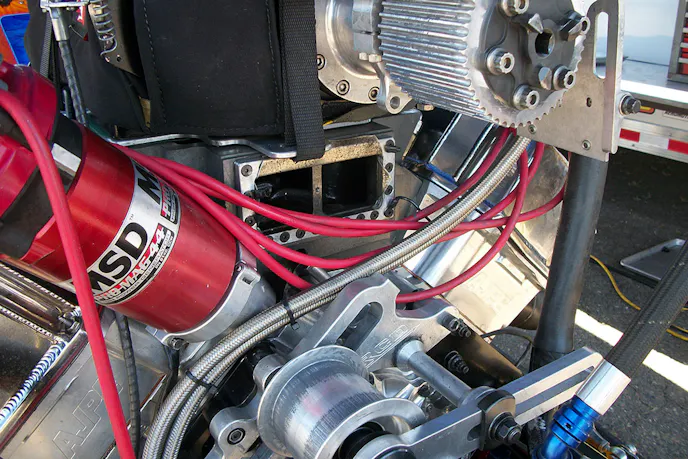

The actual ratio of the weight of air to the weight of fuel was computed over several test runs by using an MFI fuel injection jetting calculator. Fuel injection jetting was adjusted until an optimum spark plug reading was achieved. AFR values were computed by the calculator and added to the racing database. The results were optimum engine temperature and performance.

Drag racing engine combinations running methanol are routinely run fuel-rich for combustion chamber cooling in order to retard detonation and piston-melting. Total compression from the static compression multiplied by boost can exceed 30 to 1. That amount of compression will super-heat typical combustion chamber contents well over 800 degrees Fahrenheit, which can cause detonation and piston damage with most racing fuels. Methanol can be run with a lot of fuel enrichment, keeping it below the self-ignition temperature to avoid detonation. Excess enrichment beyond that chills the cylinder content and costs power. There is an optimum AFR envelope, specific to each fuel.

Once an optimum AFR is determined for a racing engine combination, it usually remains a constant value within normal atmospheric changes. In the previous engine example, the optimum AFR of 3.4 to 1 was maintained for power levels from 900 to 2,000 horsepower. Different power levels were achieved by changing the blower setup for different classes of drag racing from 7.9-second quarter-mile e.t.’s down to mid-six-second quarter-mile e.t.’s.

The amount of fuel was changed with fuel injection jetting to maintain that optimum AFR for different blower setups and weather. With that control, consistent spark plug readings were maintained at the various power levels and air densities. Optimum performance was maintained with the various blower setups, free of dropped cylinders (from excess enrichment) or blower backfiring or engine bogging (from excess lean-out), and racing was a lot of fun.

Lambda

Lambda is a numerical value derived from the AFR. Frequently, it is used as part of an electronic fuel injection program. It is the mathematical reciprocal of the amount of fuel plus enrichment as follows:

Lambda = actual AFR / stoichiometric AFR

When the actual AFR for a fuel is equal to the stoichiometric AFR of the fuel, lambda is at “1.0” regardless of the fuel type.

For example, the lambda for gasoline running at the stoichiometric AFR is as follows:

- Stoichiometric AFR for ethanol-free gasoline is 14.7 to 1

- For highway mileage, controlling the actual AFR to 14.7 to 1 under light load

lambda = actual AFR / stoichiometric AFR

lambda = (14.7 to 1) / (14.7 to 1) = 1.0

Stoichiometric AFRs & lambdas for different racing fuels are shown as follows:

| Fuel | Stoichiometric AFR | Stoichiometric Lambda |

| Gasoline | 14.7 to 1 | 1.0 |

| E85 | 9.8 to 1* | 1.0 |

| Ethanol | 9 to 1* | 1.0 |

| Methanol | 6.5 to 1* | 1.0 |

| 50-50 nitro/methanol by weight | 3.3 to 1** | 1.0 |

| Nitro | 1.7 to 1** | 1.0 |

* ref Fuel Injection Racing Secrets, 2nd edition, p. 175, Szabo Publishing, 2014

** ref Don Jackson Engineering (DJE)

Any fuel that is run on the highway, for boating, for aircraft, or for power generation is usually run at the most economical AFR, which is generally the stoichiometric ratio, or 1.0 lambda.

Lambda and Electronic Fuel Injection (EFI)

EFI programmers most often display a fuel map that controls enrichment for different operating conditions. Different lambda values can be generated by a fuel map program in the EFI controller. Racing EFI setups most often give the tuner the ability to tailor the fuel map to a specific performance need, such as increased enrichment for throttle action, acceleration, anti-stumble, or cooling. Some controllers are programmed using AFR, while some are programmed using lambda. Some higher-end software offers the ability to switch between the two, to suit the tuner’s preference.

Lambda and Mechanical Fuel Injection (MFI)

Lambda isn’t just used in the EFI world. Lambda was computed for the previous example of a blown methanol racing engine running mechanical fuel injection (MFI) as follows:

Actual AFR = 3.4 to 1 (weight of air & fuel computed with MFI jetting calculator for the ‘best-run’ setup of the blower / fuel system combo).

Stoichiometric AFR for methanol = 6.5 to 1

Lambda = (3.4 to 1) / (6.5 to 1) = 0.52

AFRs & lambdas were computed for other operating modes of this racing engine as follows:

| Operating Mode | Air/Fuel Ratio | Lambda |

| ‘HP peak’ AFR too rich misfiring | 3.1 to 1 | 0.48 |

| ‘HP peak’ AFR optimum | 3.4 to 1 | 0.52 |

| ‘HP peak’ AFR melted 2 pistons | 3.7 to 1 | 0.57 |

A fuel mapping study for MFI was just started for the operating modes as follows:

| MFI Fuel Map Run Time Mode | Air/Fuel Ratio | Lambda |

| idle* | 2.9 to 1 | 0.45 |

| staging** | 3.1 to 1 | 0.48 |

| launch (best) | 3.2 to 1 | 0.49 |

| HP peak (best) | 3.4 to 1 | 0.52 |

| HP peak + 200 mph ram air*** | 3.6 to 1 | 0.55 |

* oil temp was 140°F after 5 minutes idling in 80°F weather; excess enrichment was used for cooling for this setup w/o a cooling system; the engine ran cooler from a richer idle AFR; it ran hotter from an Idle AFR that was less rich.

** oil temp. staging at 150°F; richer AFR at staging reduced oil temp. at staging.

*** oil temp. end-of-run at 180°F; richer AFR reduced end-of-run oil temp.; an AFR that was less rich increased the end-of-run oil temp., however the engine was run conservative for longevity.

All AFR values were determined with an MFI jetting calculator staged for the various modes of operation. As air density would change, jetting was always determined ahead of time to maintain the best launch and horsepower-peak AFRs including the effects of ram air. AFR control provides very good numerical control over a tune-up.

The Blower and Air Density Changes

Air density differs from changes in track altitude and weather; the blower overdrive can be changed to compensate. For example, a blower overdrive of 18-percent at sea level on a warm day produced the same quarter-mile e.t. as a blower overdrive of 45-percent at a 5,500-foot-elevation track on a hot day. In both cases, the fuel system was not changed, only the blower pulleys. After determining the appropriate blower overdrive for that change from altitude and weather, out-of-the-trailer performance was identical for the two dramatically different locations.

Lambda and AFR meters are often connected to the exhaust of racing engines to generate these values for tuning. It is important that the exhaust must be free of air leaks before the oxygen sensor location in the exhaust pipe. Any air leaks in the intake or exhaust system will pull in outside air during intake and exhaust pulses introducing error in the reading.

Conclusion

The Hemi engine example in this article could be very well tuned with AFR adjustment for air density or blower setup changes. In over 1,000 drag racing passes, this Hemi engine never melted a piston or suffered a backfire in the blower manifold. AFR control provided very good numerical control over the tune-up. Lambda values are simply a different way to express the AFR and are computed from AFR values. Lambda is a common parameter in EFI controllers that provides AFR control over a tune-up, and are nothing to be afraid of in the tuning world.

Ref: Ricardo, H. & Clyde, H. (1941). The High-Speed Internal-Combustion Engine.

You might also like

Diving Into What Synthetic Oil Really Is... And Isn't

Synthetic oil is one of the most debated topics in automotive. We break down API oil groups, base stocks, additives, and how to choose.