A few years back, we brought you Jeff Huneycutt’s video on Newcomer Racing smashing the Jeep inline-six-cylinder power record. Well, Keith Newcomer is at it again, and once again, The Horsepower Monster is along for the ride to bring us the adventure that is Jeep engine world-record hunting.

This particular engine project features a lot of parts that Newcomer had lying around. While that might seem dismissive of the quality of parts used, the fact is, when you are as heavily into research and development on the Jeep 4.0-liter inline-six engine as Newcomer is, what is lying around is some pretty badass stuff. “The head is an R&D project,” says Newcomer. “Some of the turbo parts are left over from a project 10 years ago, and we pulled them out of the closet for this. We’re going to try and see what it makes.”

World Record Building Blocks — Not Quite Legos

This particular short-block is built with components for another turbo project Newcomer developed, albeit with much lower horsepower goals. He started with a newer OEM block, known as the “NVH” block. NVH, standing for “Noise, Vibration, and Harshness,” the NVH block is a stronger variant of OEM block that should hold up to Newcomer’s record aspirations. Unlike the previous record-setting effort we reported on, this block is not filled with hard block, and remains in its factory configuration.

I’ve heard the critics for years, telling me I could run more compression on these turbo engines. — Keith Newcomer

While the stroker crank used is cast, not forged, it is a fully-counterweighted unit. On the right are the custom JE pistons and forged SCAT connecting rods reused for this project.

However, the crankshaft is not factory, using a fully counterweighted cast 3.895-inch-stroke crankshaft to significantly increase the combination’s stroke. A set of SCAT forged I-beam connecting rods are bolted to the crankpins, with a set of completely custom JE forged 3.905-inch pistons hanging off the rods, making for a new displacement of 4.6 liters. Now, the pistons are dished because they came out of a previous low-compression build. But, this combination is not going to have low compression. Remember, there is more than one way to skin a cat when it comes to compression ratio. More on that in a minute.

The main bolts, main caps, and main girdle are all 100-percent factory pieces. They are exactly the same as you would find in any other Jeep 4.0-liter engine that rolled off the assembly line. No stronger bolts, no better materials, and no hot rod tricks. However, Newcomer did opt for an ATI Super Damper to keep any harmonics in check. He’s already playing with enough fire with the mains.

Compression Plus Boost

“I’ve heard the critics for years, telling me I could run more compression on these turbo engines,” says Newcomer. “So, this one is 11.8:1, and we’re going to throw the boost to it and see what it takes.” Now, you might be asking how he’s going to make it 11.8:1 if he’s using old dished turbo pistons. Well, remember that R&D cylinder head we mentioned at the beginning of all of this?

The cylinder head started out life as an Edelbrock Performer aluminum cylinder head, before Newcomer took advantage of the extra-thick deck, and took material off to reduce the volume of the compression chambers, which, in turn, raised the compression ratio. Newcomer also worked over the intake and exhaust port shapes, both adding volume and optimizing the airflow path. He also reworked the valve seats and added larger valves to take advantage of the larger, better-flowing ports.

In order to compensate for the dish built into the piston, Newcomer decked the Edelbrock Jeep head as part of the complete rework process. This brings up the compression ratio to 11.8:1.

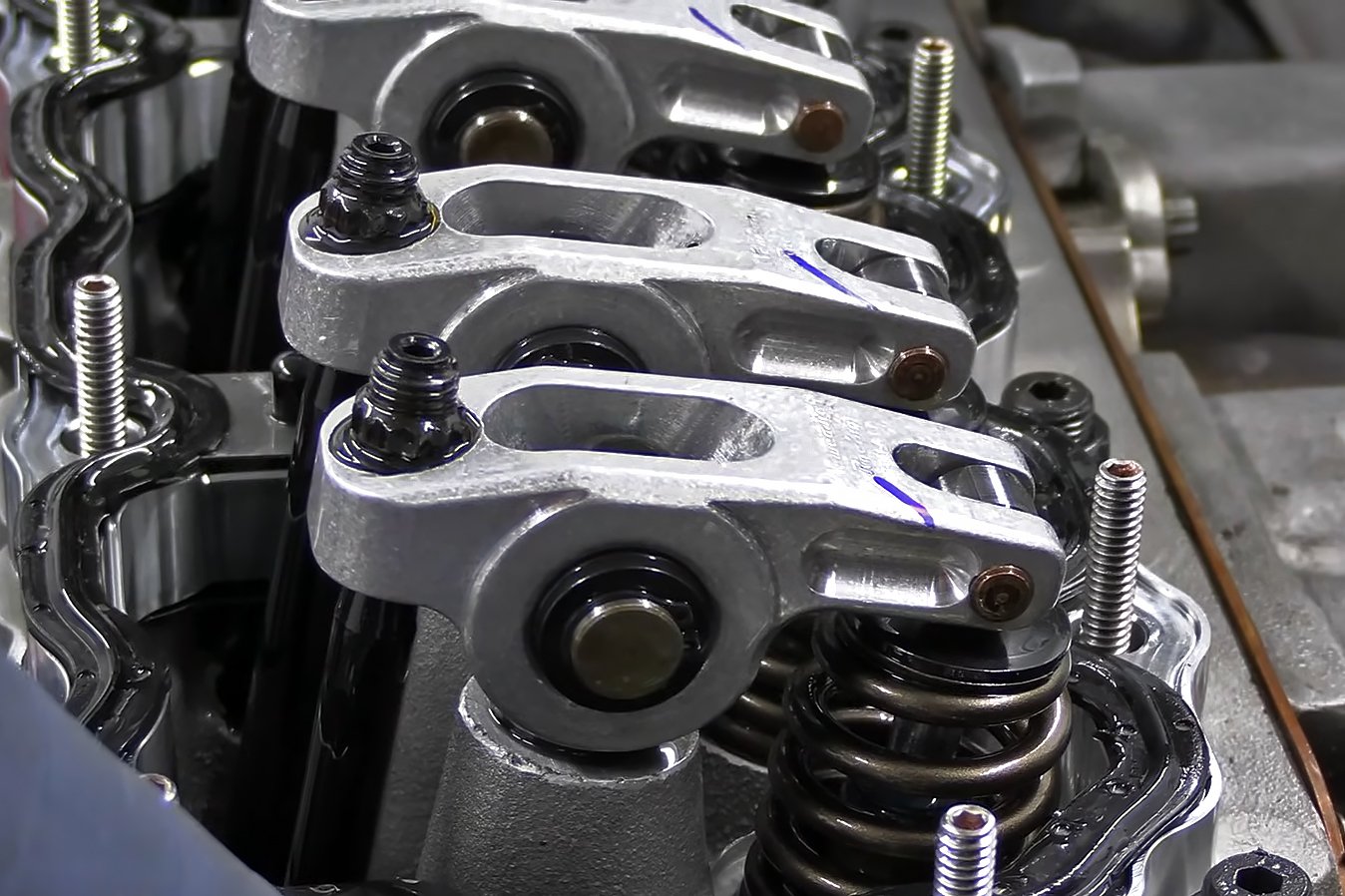

Controlling those valves is a custom camshaft, with the only specs shared being that there is .540 inch of peak lift and 236 degrees of duration for both the intake and exhaust valves, with a 113-degree lobe separation. A set of Newcomer’s own roller rockers sit atop the cylinder head, with this set being a 1.7:1 ratio, with the screw adjuster option, along with the full rocker-arm lightening program.

Feeding the cylinders is a Holley 650cfm XP blow-through carburetor mounted atop a Clifford cast intake manifold that Newcomer has massaged a little to improve flow. The team modified the carb to work without boost as they prepared the engine to break-in without boost. In addition to the break-in process, they were curious to see how the engine performed au natural.

With everything bolted up at Tony’s Competition Engines, Tony Corrente fired up the engine and started the process. Running on Sunoco Max NOS 116 fuel, the team made some tweaks to get everything as dialed in as possible without the turbo, and were rewarded with 394 horsepower at 6,100 rpm and 375.5 lb-ft at 4,600 rpm. When you consider this combination is optimized for boost, not N/A performance, the fact that it’s only a bit off of the 417 horsepower Newcomer has seen with the right carb, cam, and exhaust is pretty impressive.

[This engine] will be fuel injected next time, and I guarantee that it will make more than this, with a lot more control. — Keith Newcomer

Newcomer has a line of rocker arms for Jeep 4.0s manufactured to their specs. These are the top-of-the-line 1.7:1 adjustable aluminum rockers with a full lightening program applied to minimize weight while maximizing stiffness.

Free Horsepower

Since they were in the testing mood, and had the dyno all day, the team decided to test something else kind of oddball. It’s often said that turbos are “free horsepower” compared to superchargers, because they use waste exhaust to drive the compressor, instead of the crankshaft. One thing that’s not often considered is the effect of putting a turbine into the exhaust flow has on overall power production.

So, they tested it. By connecting the turbine to the exhaust manifold, but leaving the compressor discharge disconnected from the engine’s intake, they could see the power difference with the turbo installed, with an apples-to-apples comparison. The result? A peak difference of 37.5 horsepower and 36.2 lb-ft, and an overall average loss of 29.5 horsepower and 28.1 lb-ft of torque across the powerband. I guess turbos aren’t quite “free” horsepower after all.

While attempting to eclipse the 1,000 horsepower mark, the center two cylinders went lean, leading to these cool glowing primaries. Luckily, nothing was hurt, and the team simply richened up the mixture.

Now, for the main event. With the carb converted back to proper blow-through spec, the Precision 72mm mid-frame turbocharger plumbed back into the system, it was time to go for that previous world record Newcomer set. However, the 72mm turbo just wasn’t enough to get them past that 861 horsepower mark. At 27 psi, the engine made 812 horsepower and 715.9 lb-ft of torque. But, that’s not the end of the story.

Newcomer had a secret weapon in reserve — A Pulsar large-frame 77mm turbocharger — leading us to believe he was preparing for the inevitable hunger that one experiences on the dyno when you are “that” close to meeting a goal. While the turbo swap almost immediately broke the 861-horsepower barrier, it lit the fuse on shooting for an even thousand.

With the mid-frame 72mm turbo running out of steam, Newcomer busted out the secret weapon — a large-frame 77mm Pulsar turbocharger. Rated at 1,500 horsepower-worth of airflow, it brought all the boost needed to the table.

After getting dang close, while also turning the middle two exhaust primaries into night lights, they did some rejetting of the carb to fatten the mixture up. When the dyno released the engine, it ran hard enough that Newcomer (who was now running the dyno, since Corrente had long since gone home for the day) yanked the throttle back quite early, with the run ending at 5,600 rpm. Both horsepower and torque were still climbing, but the numbers were there.

1,082.6 horsepower and 1,017.7 lb-ft of torque, all from a 4.6-liter Jeep inline-six, with no block-filler, factory main caps and bolts, and a 650cfm carburetor. This makes it, as far as anyone currently knows, the most powerful Jeep inline-six engine ever. And Newcomer isn’t done, especially after seeing the dyno graph skyrocketing when he pulled the handle.“[This engine] will be fuel injected next time, and I guarantee that it will make more than this, with a lot more control,” says Newcomer. You’d better believe we are excited to see that one!

Make sure to watch the full Horsepower Monster video linked above to hear all of the noises and see all of the action that took place in the dyno cell.

The three different traces represent the baseline naturally aspirated pull, then the best attempt with the smaller turbocharger, and then finally, the money run with the larger turbo. Notice that the bigger turbo was far from done, but the carburetor was dangerously out of fuel, so Newcomer pulled the handle early.