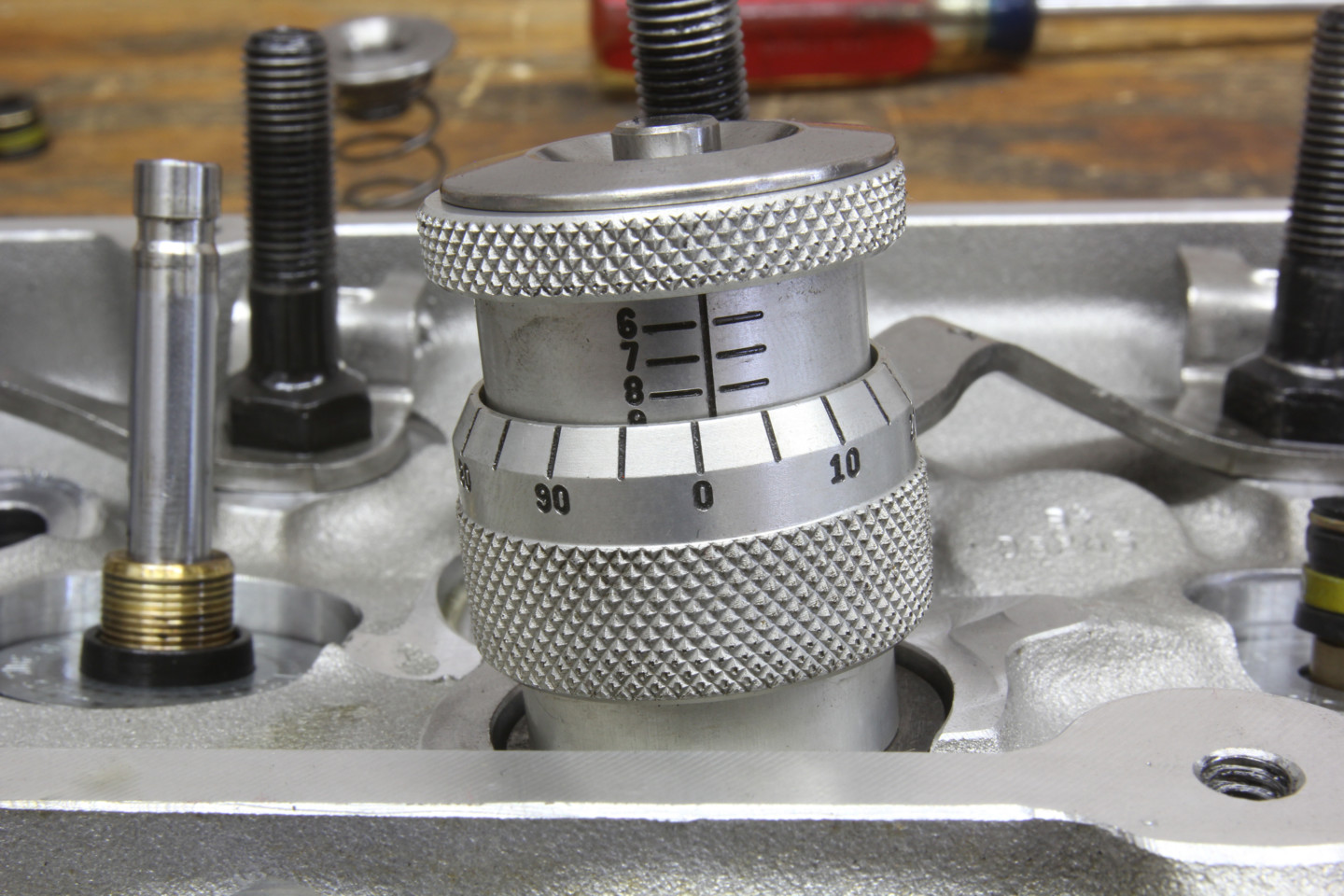

Today, even home-shop engine building is much easier with a host of affordable tools that make the process less of a burden. But it wasn’t always that way. Take for example, how easy it is to check valve spring installed height with the aid of a simple tool called the spring height mic. This tool is a specific micrometer designed to install over the valve and to quickly measure the height between the spring seat on the head and the underside of the valve spring retainer.

But if you don’t have one of these cool little tools, there is another simple way to measure installed height, it just takes a little bit of preparation. We’ve tried using our dial calipers, but generally, there isn’t enough room. You could also use a snap gauge and then measure its height with calipers, but our friend Don Barrington, Jr. told us how his dad Bon Barrington, Sr. did it back in the days before height mics.

This is a valve spring height micrometer. You install a valve in the guide and then place a retainer and locks over the top of the mic on the valve. Then adjust the height of the mic until it takes up all the clearance. The scale will indicate the installed height of the spring. Here, on this big-block Chevy cylinder head, the height is a touch over 1.900-inch.

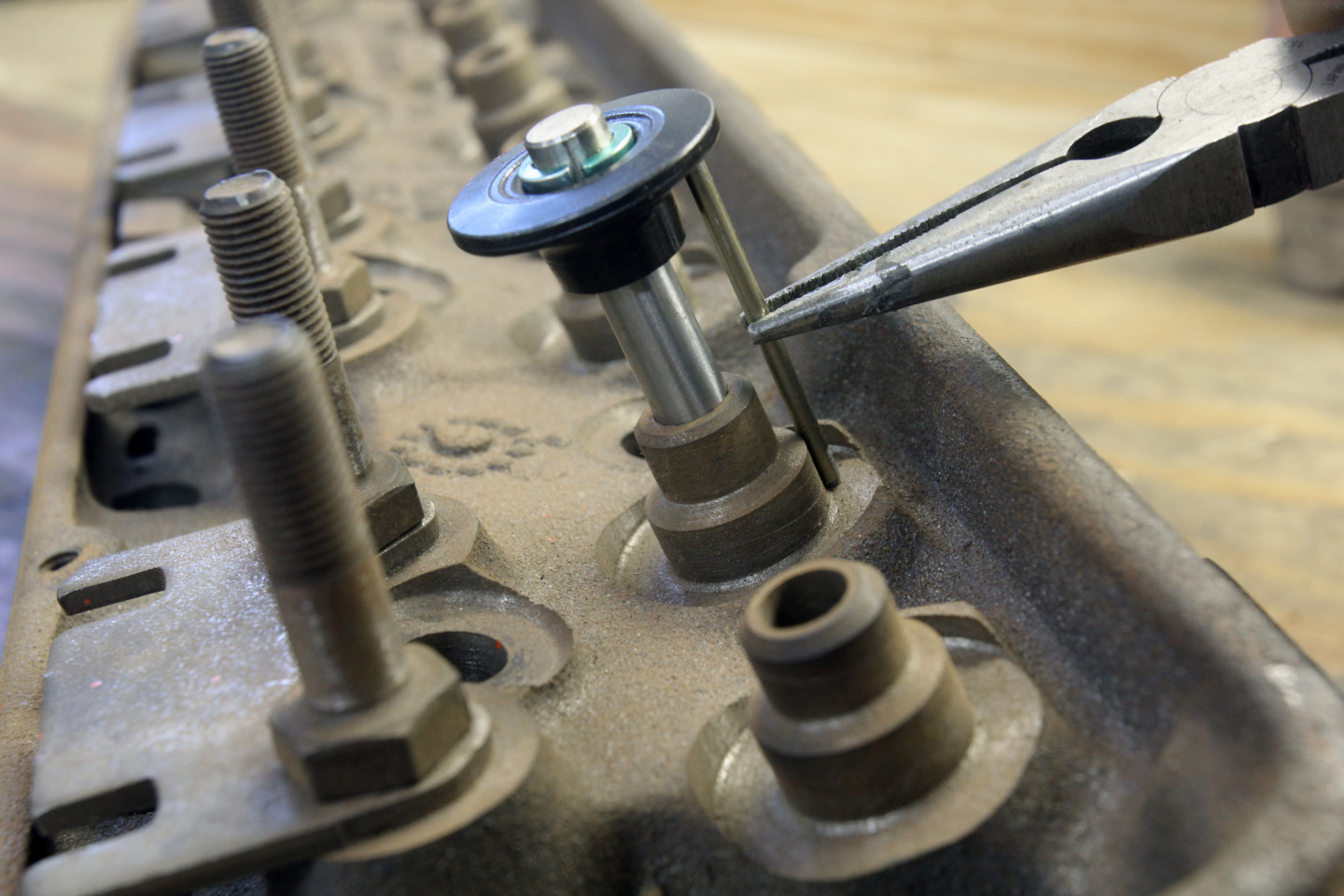

Barrington, Sr. used some thick steel dowel stock, about 1/8-inch in diameter, and cut them in various lengths corresponding to the desired installed height. Then with each valve assembled with its retainer and keepers, he’d merely use the dowels to establish the height. If the dowel was too long to fit, it was obviously too short and would need extra clearance with different keepers. If there was clearance between the checking rod and the retainer, he could install shims needed to establish the desired height.

This is a great way to measure installed height when you don’t have access to a height mic but still need an accurate measurement. It’s certainly old school, but it will work!