Education and knowledge are essential in any industry if you want to be successful, especially in the high-performance aftermarket. The School of Automotive Machinists & Technology (SAM Tech) was founded by Judson and Linda Massingill to give individuals the opportunity to learn how to be true craftsmen in the motorsports industry. In this article, we speak with James Stray from SAM Tech about how the school creates well-trained graduates for the high-performance industry.

Currently, SAM Tech offers different programs that teach students how to become skilled engine machinists. Students can earn certificates in engine block, cylinder head, and CNC machining, along with EFI calibration. An associate of applied science degree in automotive engine/block & cylinder head machining is also offered by SAM Tech currently, too. Graduates of SAM Tech can be found all over the automotive industry at top manufacturing companies, race teams in major series, and many go on to start their own shops.

The Programs

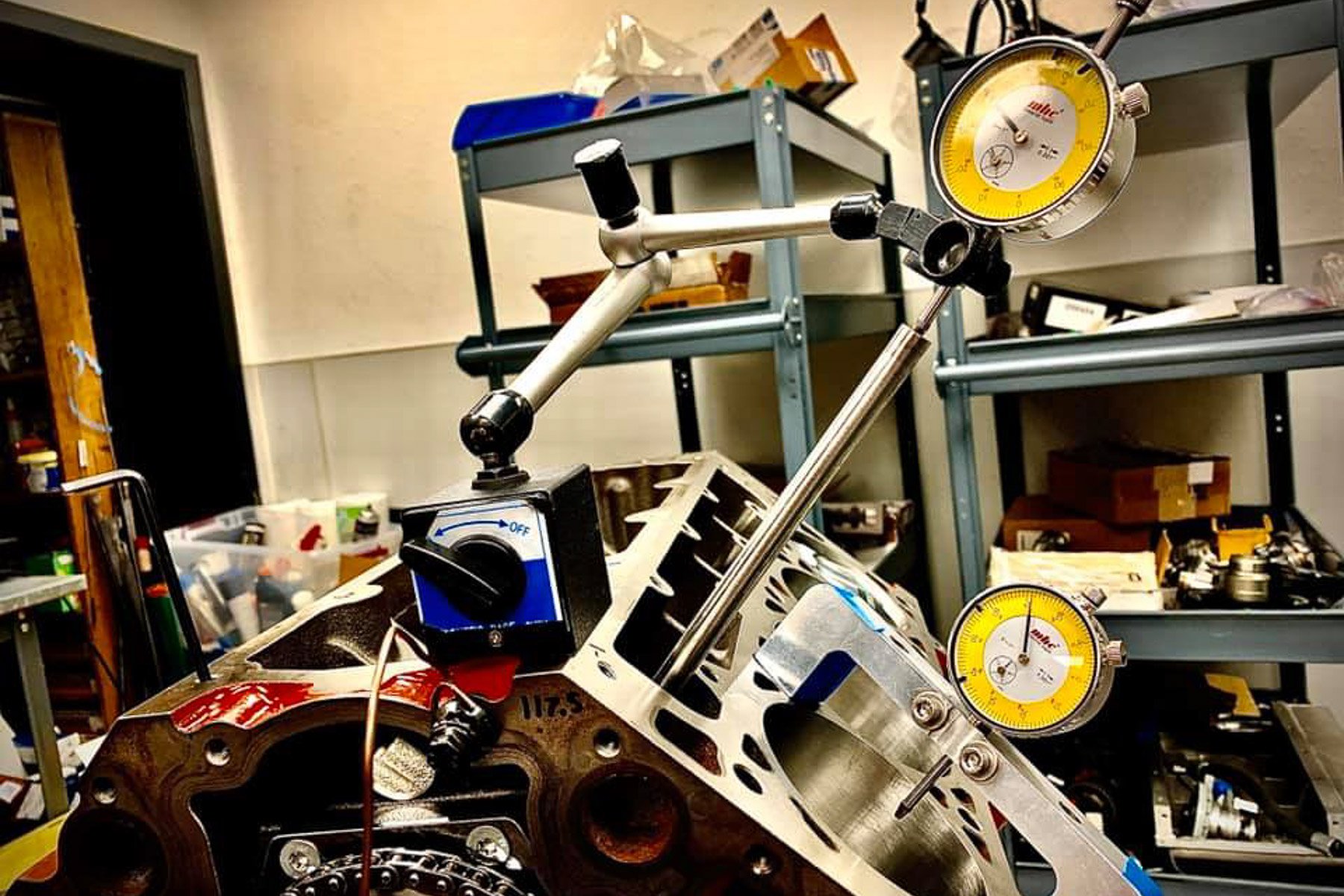

When students graduate from SAM Tech they will be armed with the knowledge of how to build an engine. The first step in any engine build is getting the block ready, and SAM Tech’s block program is designed to teach students about more than just the machining process. Each student is educated on how a modern racing engine operates, and this begins with a deep dive into how engines function at the most basic level. Machining skills are taught during this entire course where students learn to refine their skills before they complete a proficiency test in each area.

“The students also go through an intense teardown and assembly of a modern engine — this is an A-to-Z on short block building. Justt a few of the things covered are measuring tolerances, proper installation, and setting of bearing clearances, ring filing, cam degreeing and checking piston to valve clearance. We also spend several days in the dyno cell where the students learn how to load engines, as well as how to operate the controls when making pulls with one of our mule engines,” Stray explains.

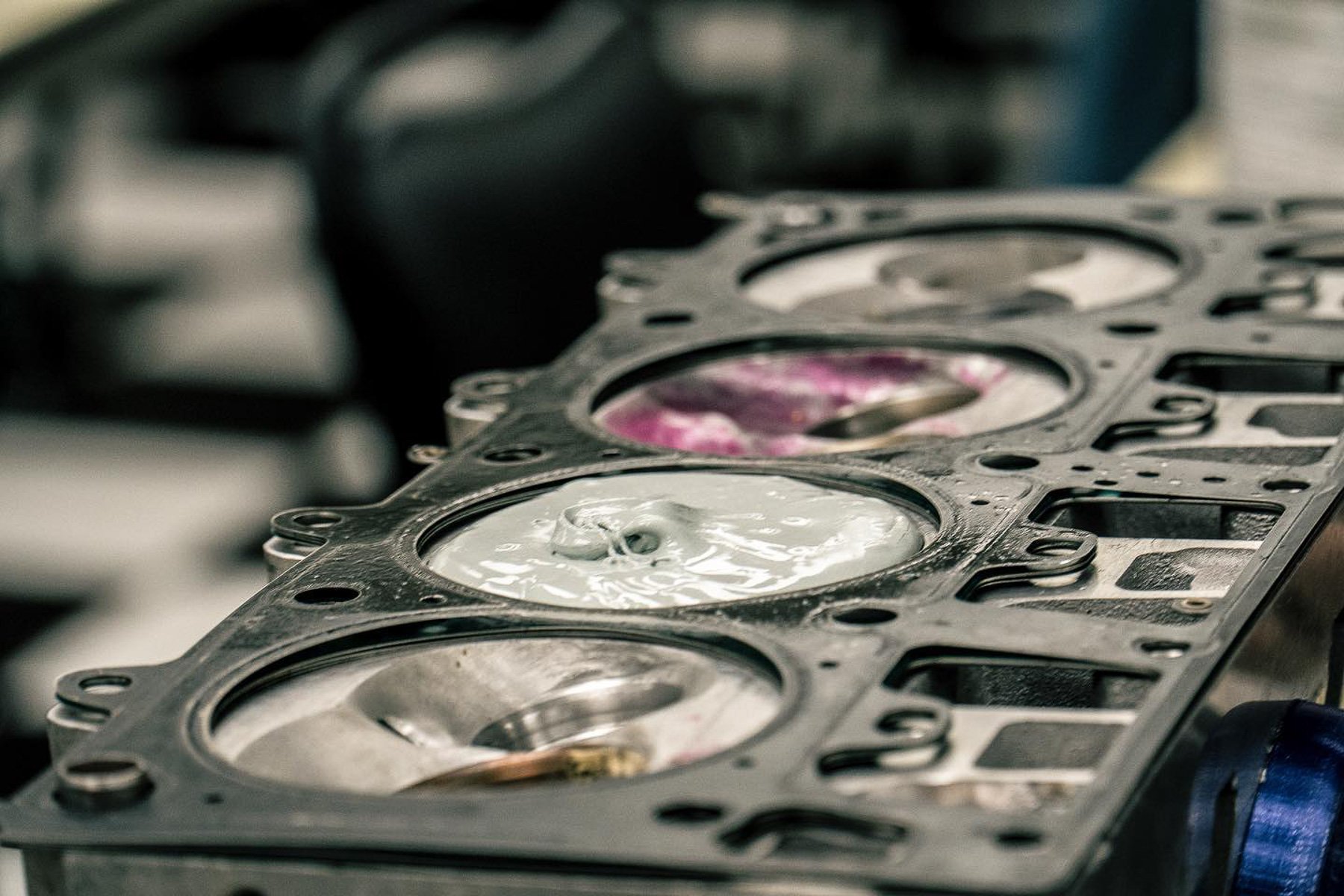

Cylinder heads are another area that SAM Tech focuses on when it comes to providing students with a well-rounded mechanical education. Students learn about cylinder head theory and what role heads play in how a high-performance engine operates. Instructors show the students airflow characteristics and how they affect an engine’s performance. Students also learn what each component of the cylinder head does and how to fully assemble a cylinder head.

“Students start their day in the classroom and after the lecture is concluded for the day they spend the rest of the time in the shop practicing the skills that they have been taught. At SAM Tech, the students are taught everything, from how to rebuild and machine stock heads, all the way up to machining and servicing high-end racing heads. This provides students with the most knowledge so they can to work with any employer in the industry,” Stray says.

CNC machines are common in many high-performance engine shops, so SAM Tech added courses on how to operate these machines to its curriculum. Students get to learn how a 5-Axis CNC machine works, along with how to digitize parts using the Faro Arm, they also are taught how to reverse engineer parts, and how to modify cylinder heads with a CNC machine. When students have completed this program, they’re Mastercam certified and they understand how G-Code, the CNC programming language, works.

Modern muscle cars and many race cars now use EFI systems and tuning them properly isn’t easy. SAM Tech wanted to ensure it was on the cutting edge of high-performance education, so it added Motorsports EFI Calibration as a certificate.

“The program objective for the Motorsports EFI Calibration program is for students to learn how to calibrate and troubleshoot an engine management system on the engine dynamometer, chassis dynamometer and at the racetrack. This program includes instruction in adding performance accessories, modifying power trains, tuning custom engines, suspension, exhaust systems, and using dynamometers and other diagnostic tools. The course also is comprised of engine theory, basic wiring and electrical theory, the factory and aftermarket calibration process along with data collection and analysis,” Stray says.

SAM Tech does more than just teach students how engines work and how to run machines — the school prepares students to further their education and earn a bachelor’s degree if they want at another university through its Associates of Applied Sciences.

“In addition to the technical courses, students will take Introduction to Communications, College Algebra, Introduction to Physics, English Composition, and Sociology to complete their degree. Graduates have begun careers as business owners or engine builders with progression to team leadership. Many have combined the education and skills they acquired at SAM Tech to pursue a degree in mechanical engineering. The program provides an ideal foundation for professional development and continuing higher education,” Stray explains.

Industry Ready Graduates

SAM Tech takes great pride in the fact that it prepares its students for the real world. Instead of just teaching theory or how to work a machine, SAM Tech has developed courses that meld both of these practices together so students can be placed in the workforce immediately after graduation.

“Performance engine building is very competitive. While other schools have short performance modules, we are solely dedicated to making horsepower and this is reflected in our student’s abilities. The intense machine training, as well as the thorough instruction given in the theory portion of our courses gives students a clear advantage above the rest in the high-performance industry,” Stray states.

Course materials can become stale since technology, techniques, and tools evolve at such a rapid pace in the high-performance aftermarket. SAM Tech is constantly revising its courses to match what’s going on in the industry — this ensures its students can perform at the highest level when they start their career. Things like the latest trends in cylinder finishes, proper valve geometry and porting for maximum performance, the latest CNC Mastercam programming, and plenty of EFI lab time with new software are all kept fresh at SAM Tech.

Students leave SAM Tech armed with the skills they need to start their own shop. Some students might not be ready to go into business for themselves right away, but SAM Tech has deep roots within the performance aftermarket industry and that allows them to land a job after graduation.

“We have been in business a long time, building relationships with companies like Roush Yates Engines, Hendrick Motorsports, BES Racing Engines, Kalitta Motorsports, Don Schumacher Racing, Jon Kaase Racing, and many more. We typically have more employers calling wanting to interview our students than we have graduating. The sky is the limit and our job placement team makes every effort to see that each and every one of our graduates get a great job. For many graduating programs our placement averages just under 100-percent,” Stray states.

SAM Tech gives students the chance to learn so many skills that can put them on a path to success within the high-performance industry. The hands-on portion of the different programs are just one part of SAM Tech’s comprehensive approach, the school gives students a full classroom education in the art of generating horsepower. To learn more about what SAM Tech offers make sure to check out the school’s website right here.