I’m going to start off by being real: I know there are a lot of you who don’t torque bolts outside of critical fasteners. I also know that there are even fewer of you who torque bolts that you might typically regard as being fine at “hand tight.” While this is a Tool of the Month feature, give me a minute to explain why an inch-pound torque wrench is an important tool to have in the shop.

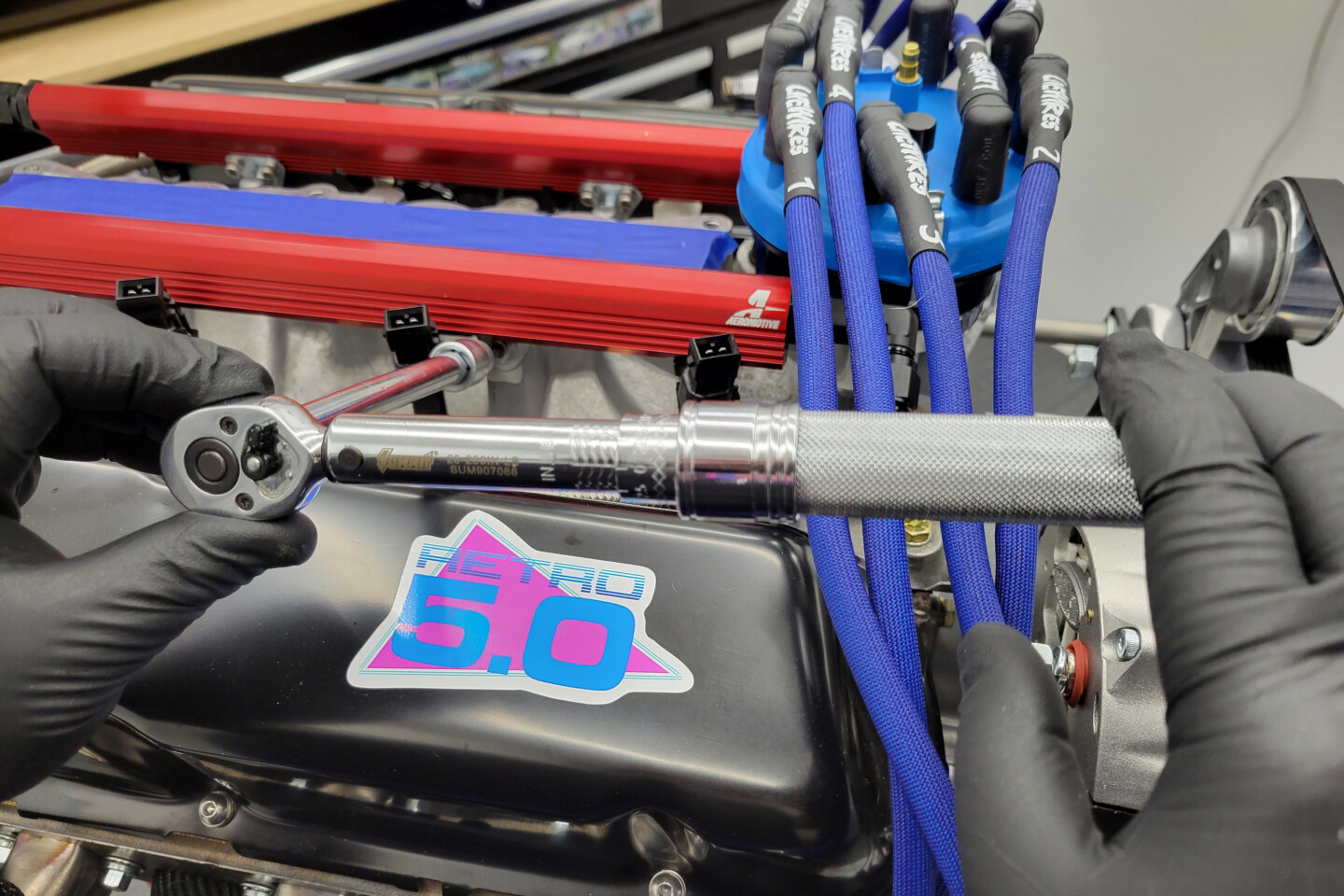

The Tool Itself

To start, the Summit Racing pound-inch torque wrench (P/N: SUM-907066) is a click-style wrench designed to accurately measure torque between 25 lb-in and 250 lb-in. (There’s also the P/N: SUM-907065 with a 1/4-inch drive and 30-200 lb-in range). It’s got a durable chrome finish to keep any kind of corrosion away, and has a ball-bearing adjustment system with a locking slide collar to keep the adjustments smooth and accurate.

This model (P/N: SUM907066) features a 3/8-inch square drive and measures a range of 25-250 lb-in. If you prefer a 1/4-inch square drive, there’s P/N: SUM907065, which has a measurement range of 30-200 lb-in with the smaller head.

The 3/8-inch square drive is conveniently sized for the most common sockets, and if you prefer to run smaller 1/4-inch drive sockets, it’s a simple adapter away. One thing to note in the use of the wrench, is that the “click” is far less noticeable than when you are running a bigger wrench at 70 lb-ft, so you need to be paying attention for the potentially soft cam-over action alerting you that you have reached the desired torque.

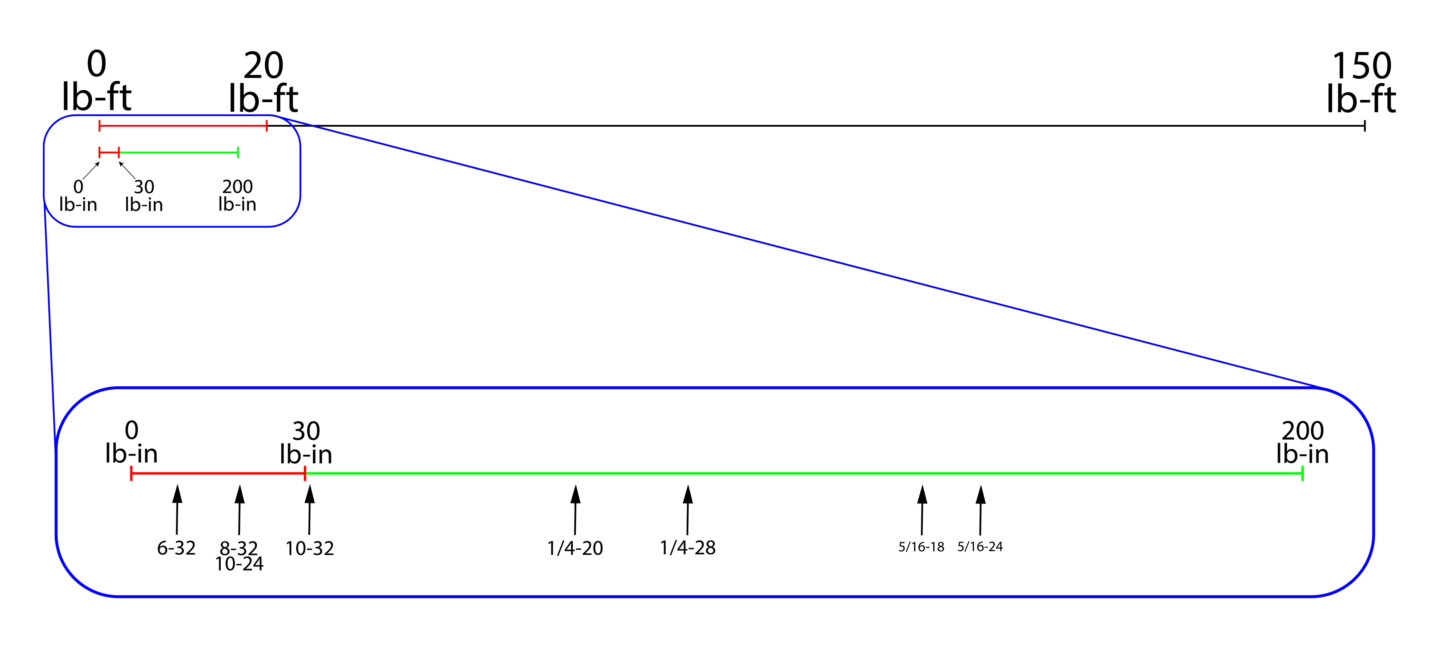

This graphic shows the scale of the torque ranges we’re talking about. The top lines are to scale with each other, and the bottom line is an enlargement of the lb-in scale, showing where various stainless fasteners’ torque values fall.

Why Not Hand Tight

We all know (or should know, anyway) about the importance of having proper torque on critical fasteners. Too much torque and you risk weakening the fastener, allowing it to fail prematurely. Too little torque and you don’t stretch the fastener enough to get the required clamp load, risking the fastener backing out. While you might think that actually measuring the correct torque on a small fastener is less important than on a large one, the opposite is true. The “Goldilocks” zone of the right torque is much smaller on a low-torque fastener than on a high-torque fastener.

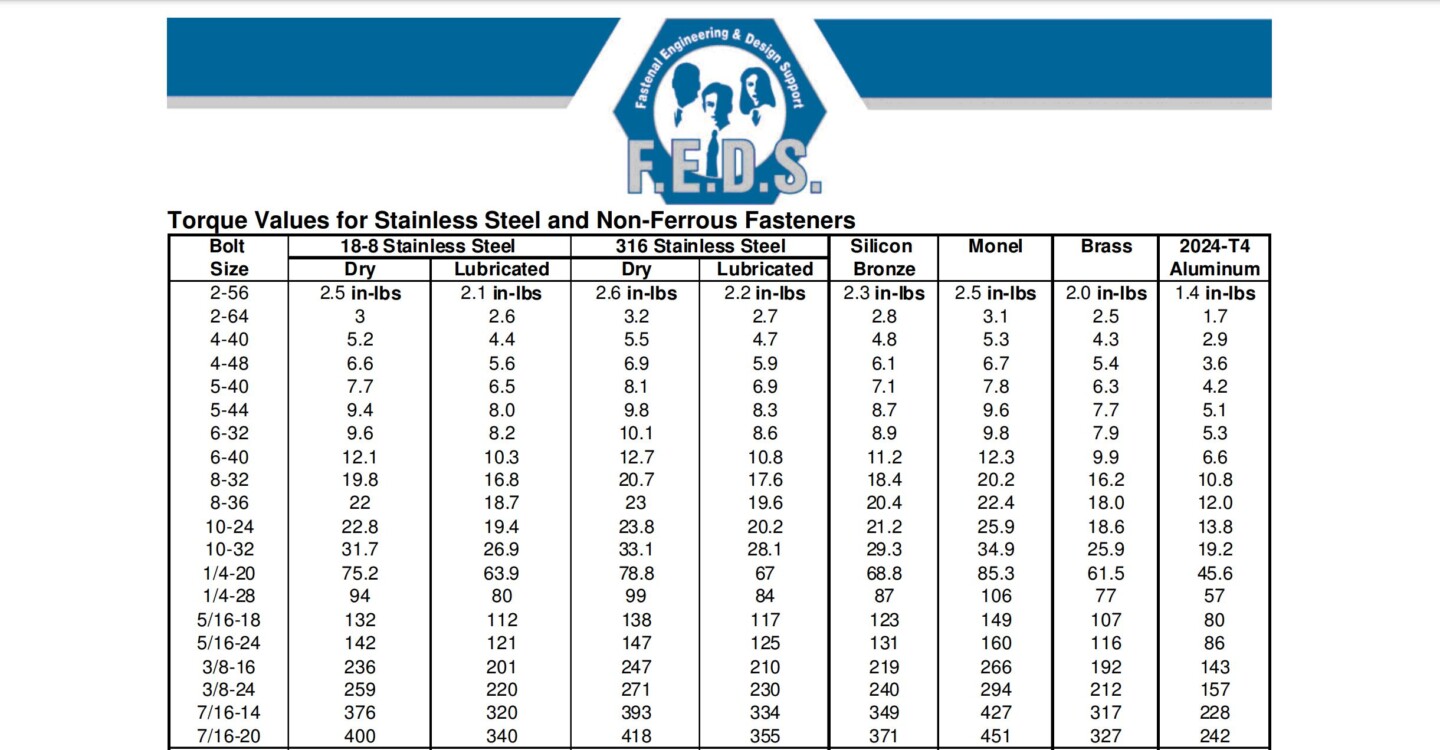

Various sizes of bolts and their ideal torque values for various materials. Note, all of these figures are in INCH-POUNDS of torque. Courtesy of Fastenal.com.

If you assume a four-percent acceptable variance in fastener torque, at 70 lb-ft that’s 2.8 lb-ft. On something that is 70 lb-in, that same variance is only 2.8 lb-in — or 0.23 lb-ft. Is your wrist calibrated to 0.23 lb-ft? Trying to find some fastener failure data, the minimum breaking strength seems to generally be 40- to 50- percent of the maximum torque value. On a 1/4-20 Grade 5 fastener, that can be as little as 140 in-lb. That means the difference between properly torqued and a bolt failure in a standard hardware-store 1/4-20 bolt is 3.5 lb-ft. Can you tell 3.5 lb-ft with even a small 1/4-inch-drive ratchet? That could be all that’s separating you from “torqued” and “broken” — and it only gets worse on smaller fasteners.

While this turned into a little more “Why to use a lb-in torque wrench” instead of “Look at this lb-in torque wrench,” it also highlights why you should not only use a torque wrench, but also use a quality torque wrench. I’m somewhat ashamed to admit I have absolutely wrecked some smaller bolts with a poor-quality lb-in torque wrench before. However, this time, it was a night-and-day difference.