Everyone stops to appreciate an original Camaro, Chevelle, or Corvette that is painstakingly reconstructed to be as close as possible to what you would have seen on a showroom floor in years past — with onlookers appreciating the effort that goes into the external appearance of a well-restored muscle car.

The challenge to take such a rare LS6 454 and restore it to as original as possible, both externally and internally, is an interesting task.

When it comes to a restored muscle car, the big-block is usually the engine of choice. In 1970, the 454 was Chevrolet’s effort to raise the stakes in the muscle car horsepower wars. Of the three versions produced, the LS6 version was the high-performance option for Corvettes, Camaros, and Chevelles. This package supplied 450 horsepower and 500 lb-ft of torque. The ’70 version of the LS6 454 was a pinnacle year as, by 1971, Chevrolet started to detune the engine.

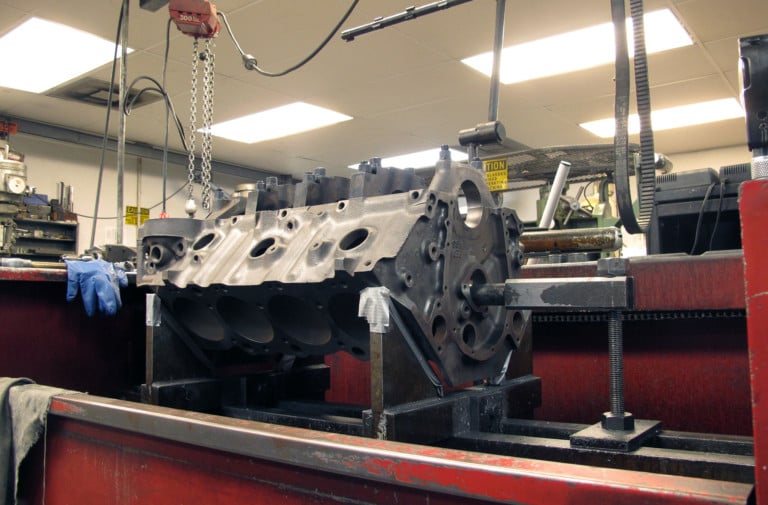

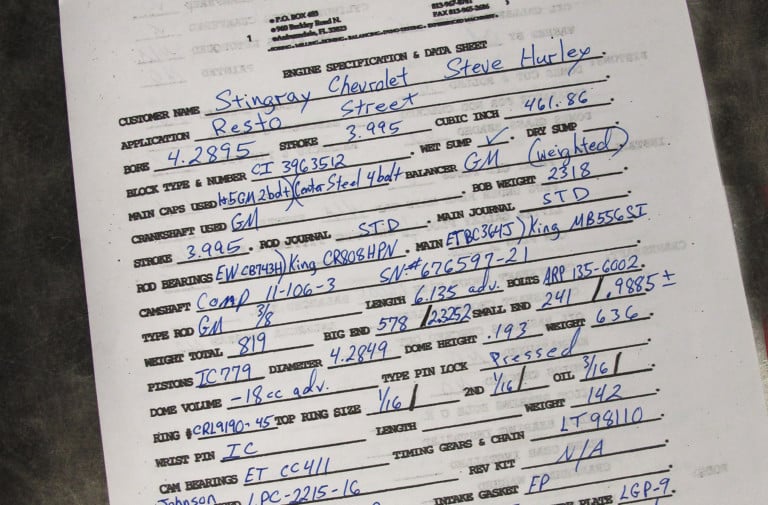

The block's dimensions and surfaces are carefully checked. Luckily, the LS6 deck did not require machining. This would have erased the very valuable serial numbers that proved the engine's rarity. A build sheet at APE logs every component installed on the project.

Plant City, Florida’s Stingray Chevrolet recently commissioned Kevin Willis at Automotive Performance Engines (APE) in Auburndale, Florida, to take a rare, serial-number-correct LS6 454 engine and return the beastly V8 to as close to original as possible. The premise of this engine build was to match the factory specs for the equally rare 1971 Corvette undergoing a full restoration. The ultimate in rarity for the pairing? The aluminum head option.

When the engine hit the floor at APE, Kevin learned it had been built to be a serious compression monster. It possessed pistons with a dome large enough to create nearly a 13.0:1 compression ratio and someone utilized MLS head gaskets that were nearly 3/16-inch thick to try and curb some of that squeeze.

Original Internals

One of the first hurdles with this rebuild was the location of original parts. Or at least, parts as close to the original components as possible. “Steve Hurley brought me the engine with the proper block, heads, and intake for the LS6 engine,” Willis tells us. “When we got inside, the pistons were performance hypereutectic pieces with performance H-beam connecting rods, a hydraulic roller cam, and other non-factory components like roller rockers.”

The block and all engine components were hot-tanked and carefully restored, except for the valve covers. That is the original LS6 paint on those. This Chevrolet low-rise aluminum intake is another one of the ultra-rare components. Since the aluminum-headed LS6 was available in the 1971 Corvette, this low-rise intake was necessary for hood clearance.

Without the original components in hand, Kevin basically became a detective, trying to locate original parts. When those pieces were not obtainable, Kevin carefully worked to find proper engine internals that conform to the factory design and specifications.

Major Building Blocks

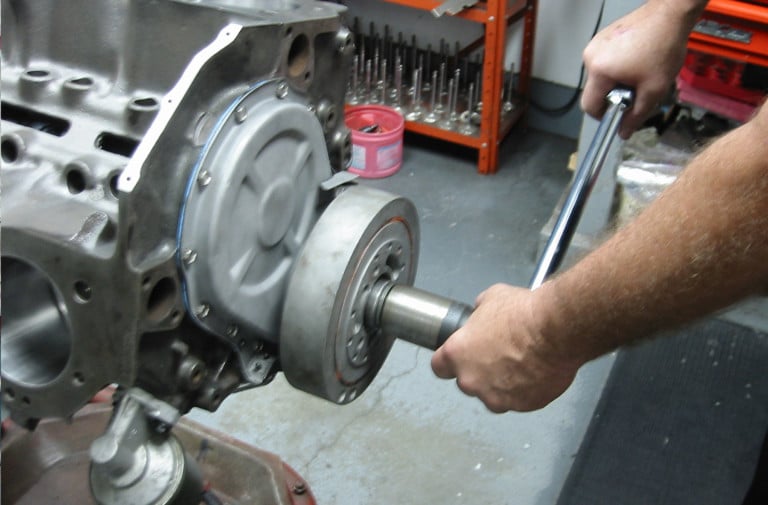

“The crankshaft was in very good shape, and we were able to retain the original connecting rod and engine-block journal diameters,” describes Willis. “We polished the crankshaft journals for good measure and we were fortunate to find some original General Motors rods that we felt very comfortable using. Since these original rods have 3/8-inch rod bolts, we did not rely on the old bolts and installed ARP bolts for the best strength.”

One of the biggest concerns with any serial number-based rarity is the need to avoid machining the deck surface, which will result in erasing those valuable stamped block numbers. – Kevin Willis

The block, with all the proper serial numbers, was carefully inspected. Luckily, all surfaces were in order, and only slight surface finishing was performed before the assembly process began.

“The original pistons were one of our biggest hurdles,” Kevin continues. “These engines [originally] used a TRW 11.25:1 piston, which isn’t even around anymore. We decided that ICON forged pistons were a very close dimensional match with a .190-inch dome height, 1.645-inch compression height, and single valve relief.”

While all components are laid out and checked for sizing and intended fit, Willis shows us the cam card for the unique COMP Cams "Factory Muscle" grind. The cam is installed with ample assembly lube on its journals before its final placement in the cam bearings.

Kevin notes that the compression ratio is very close to the original so-called blueprint, as he described. The “blueprints” Willis followed combined various manufacturer documents, plus the National Hot Rod Associations’ detailed stock eliminator specifications for that engine. The final calculated compression ratio is 10.36:1 with a 107.5cc head volume.

“We dynoed it with 93-octane pump gas,” explains Willis. “It will perform well with that on the highway without the need for any sort of racing gas.

Some Components Just Can’t Be Found

The cam is another piece that is not available in its original production form anymore. Willis looked to COMP Cams for the best solution. COMP offers their “Factory Muscle” line of cams for small- and big-block Chevrolet, as well as Olds, Ford, and Pontiac muscle car engines. The cam Willis utilized is a solid, flat-tappet cam with an advertised duration of 316/302 degrees and a lift of .520/.520-inch. Although not exact, these cam measurements are very close to the factory original.

The first models of the 454 are rare, and the LS6 454 is even rarer. Still, the unicorn of these engines is the Winters “Snowflake” aluminum heads and corresponding serial numbers. Only sold on 188 Corvettes in 1971, these heads reigned supreme in making horsepower with their rectangular intake ports, round exhaust ports, and open-chamber design.

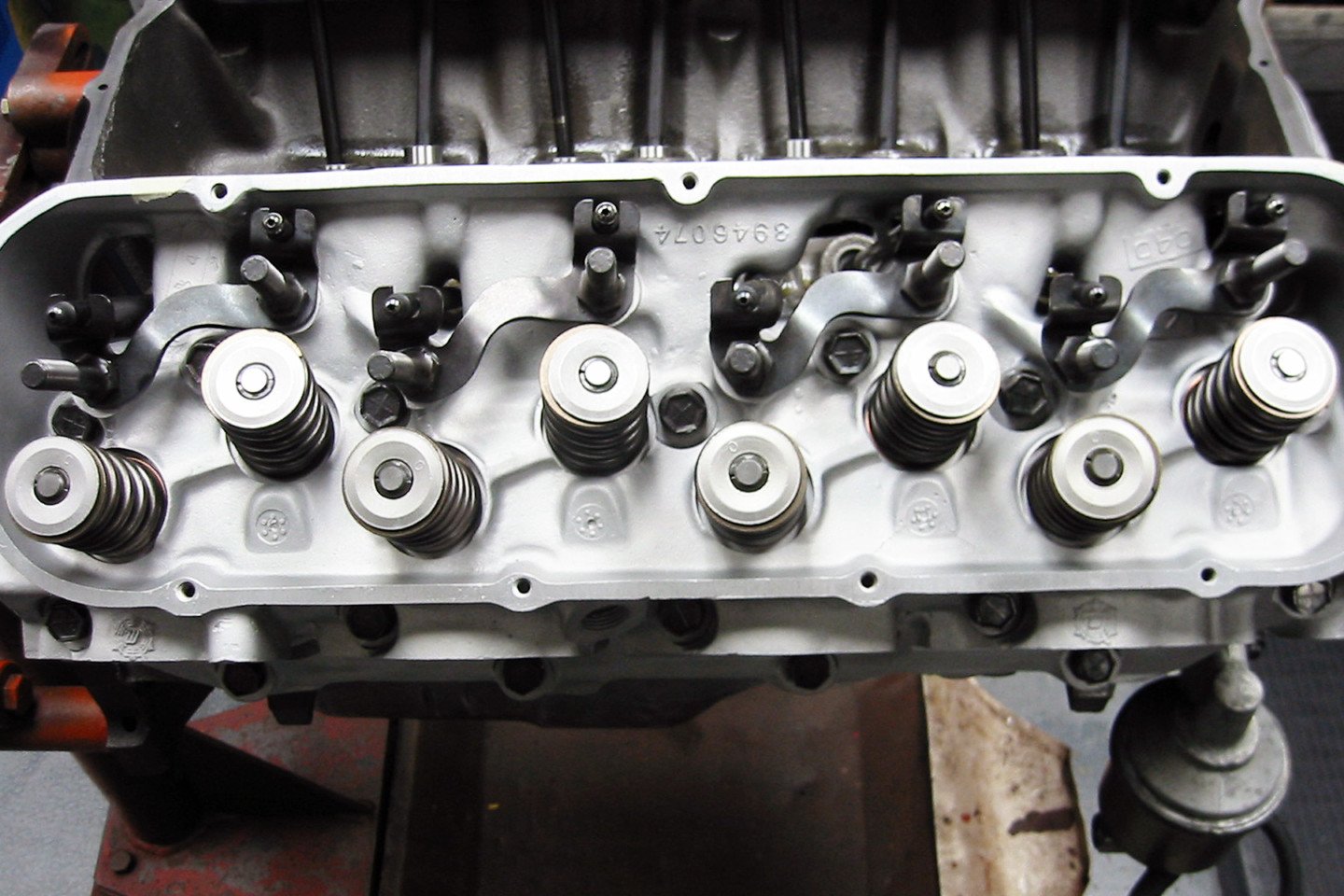

Some of the other valvetrain components that clone the original hardware include Johnson solid lifters, GM original pushrods, and GM 1.7-ratio, stamped-steel rocker arms. But where the valvetrain resides are some of the rarest pieces of all.

The “Snowflake” Heads

An aluminum-headed big-block was king of the hill in a ’70s muscle car, and this engine is equipped with the original Winters aluminum “snowflake” heads. If you think this engine itself is a rarity, our research found that only 188 of the LS6 454 engines were offered in 1971 for the Corvette with these aluminum heads. These rectangular port, open-chamber heads were, however, produced in higher numbers as Chevrolet Performance aftermarket heads. Still, combining these heads’ serial numbers with a 1971 production date stamp could make them a “holy grail” of factory cylinder heads.

The original crankshaft was carefully inspected and retains standard dimensions. It only required a mild polishing of the journals. These ICON pistons are as close to "stock" as possible and married to a set of restored era-correct rods.

“Since we are primarily a racing engine shop, we did pay attention to blueprinting details, but nothing over-the-top,” Willis states. “For example, we did not need to painstakingly dial-in the cam, but we did check the cam with a degree wheel to make sure it was where it needed to be.”

“We construct engines like these paying attention to fine details,” Willis says proudly. “It is not just put together as some shops would do with mom’s station wagon engine, but it also does not require intricate details such as those required with an extreme racing engine.”

Value-Driven Details

Another detail APE performed is a balancing of the rotating assembly. “We did balance the assembly since it is obviously a weighted 454 crankshaft,” Willis says. “Everything was pretty close, so we did a proper balance job, nothing crazy — just to be sure it ran smooth, and these rare parts will live well.”

The engine uses Fel-Pro gaskets throughout. Willis told us the deck surface was satisfactory, so they used a composite gasket simply because they are a little more forgiving.

Accustomed to building all-out competition engines, the shop pays extra attention to key points along the assembly process.

One assembly point that Willis is diligent about concerns the oil pump. “Our policy is that every oil pump is inspected for every engine that we build. The oil pump comes apart to be sure it’s clean and has no issues,” asserts Willis. “With a Chevrolet pump such as this, you just drop the little pin out, pull the spring out, pull the plunger out, and make sure it moves freely inside the bowl. They are small details to check. You don’t want it to hang up, and this ensures the spring has tension and it will have sufficient oil pressure. We always do that.”

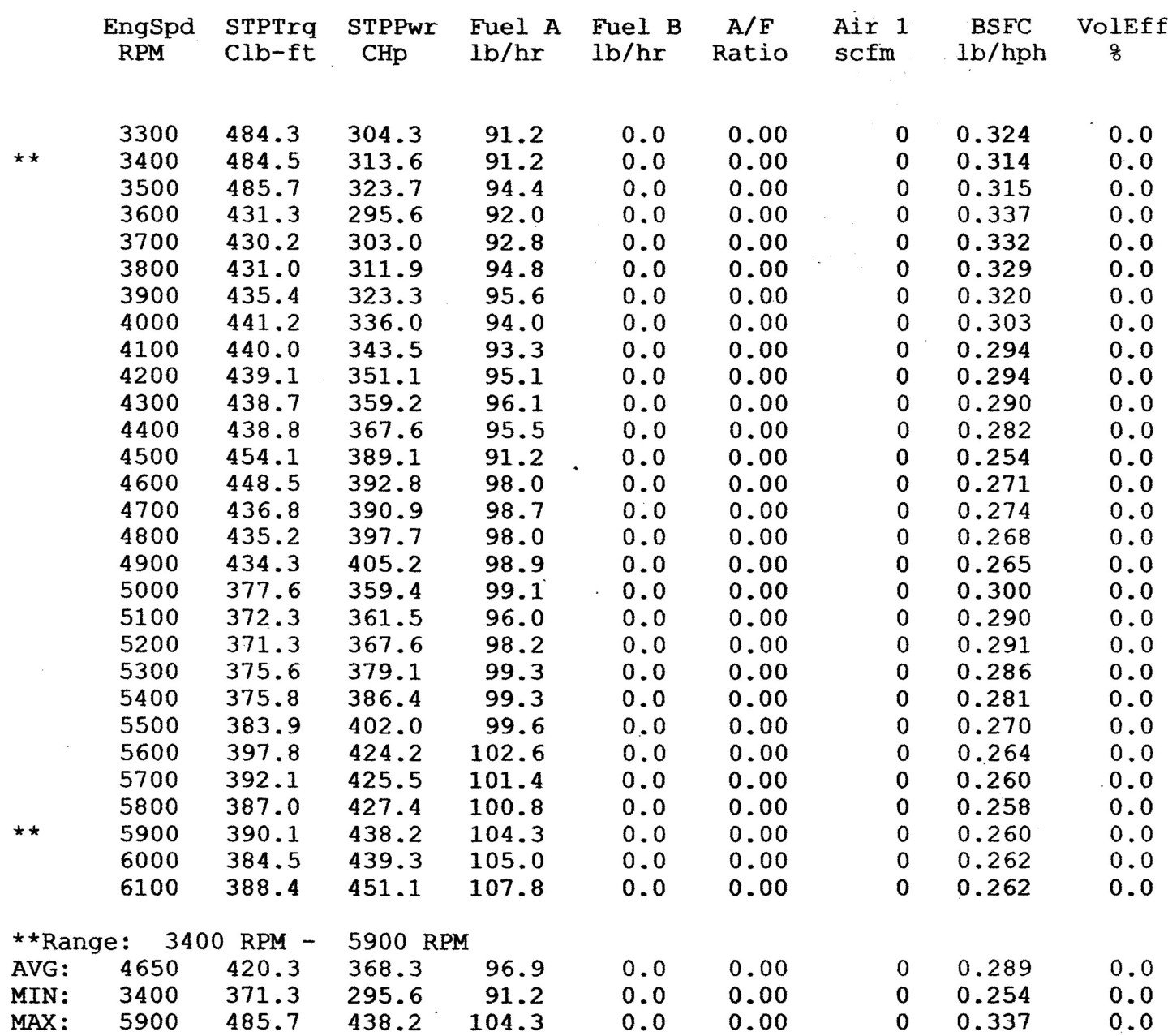

With the LS6 together, the final stop was APE’s dyno room. Willis is quick to point out that there was no reason to learn the all-out performance measurements. The dyno session was more about the engine break-in steps and ensuring there were no surprises with the completed rarity. “It basically wasn’t on the dyno to be dynoed,” chuckles Willis.

One of Willis' detail points is within the oil pump. Even though it is new, he comments, "I go through every single oil pump on any engine to make sure it is 100-percent perfect; it's just something I insist upon."

The dyno session did pull the engine to a conservative 6,100 rpm, where it provided some strong data. A peak 451.1 crankshaft horsepower was achieved at 6,100 rpm with a peak torque of 485.7 lb-ft at 3,500 rpm. Torque did diminish following that 3,500 rpm mark but remained well into the 400 lb-ft zone up to 5,000 rpm.

“It was more for breaking-in than anything else,” clarifies Willis. “That’s one reason we weren’t overly concerned about pushing the engine for big horsepower numbers. The dyno time was more to make sure that the carburetor wasn’t going to flood, and that the camshaft was properly broken in, stuff like that.”

Tucker Groce and APE owner Kevin Willis, prepare the finished engine for some conservative dyno pulls intended to check the engine and break it in. The original Holley double pumper is massive for the era, flowing 800 cfm.

Finding a rarity such as this aluminum-headed LS6 454 is notable, and taking as many steps as possible to bring it back to its original state of manufacture should be a Chevrolet and Corvette crowd pleaser.

When you consider the era of this engine, it was the final hurrah of the battles between the big-block Chevy, Mopar Hemi, and 440, and Ford’s Cobra Jet engine. Following 1971, factory performance was stifled by the EPA, resulting in lower compression ratios for the sake of a campaign against automotive emissions.

These torque-monster muscle cars from 50-plus years ago are only preserved by meticulous restorations such as this one but are revered as the golden era of engines on the dealership floors.