The ultimate goal of any racer who competes at an NHRA event is to win a Wally trophy, and that takes a flawless performance from both car and driver. Louisiana native Brandon Bakies has been able to achieve tha and that earned him a top-five finish in the NHRA Super Stock ranks in 2018. By forging a relationship with the team at SAM Tech, Brandon is ready to challenge for more victories in both Stock and Super Stock in 2019.

Brandon’s racing career first began in 1993 and lasted until 1999 when he decided to take a break for about 10 years. When he returned, he wanted to jump right back into NHRA Stock Eliminator class racing and he eventually found his way into Super Stock, too.

“My dad raced Stock Eliminator so I grew up around it. He had a 1970 Oldsmobile Cutlass so when I got old enough to drive that was the car I raced. Over the years I had some good success with that car at the local and regional level. The Olds I race now is a car that my dad built for a friend that decided they didn’t want to race anymore. My dad bought it back and I started driving it,” Brandon says.

The challenge of Stock Eliminator is more than enough for some racers, but Brandon isn’t like most racers. When the COPO Camaro was released Brandon was at No Problem Raceway and Allen Patterson came to the track with his new COPO. The car really caught Brandon’s eye and right then he knew he needed one of his own.

Working with SAM Tech with the engine program has been great. They give me a lot of support and help to keep me racing at such a high level. – Brandon Bakies

“As soon as I saw Allen’s car I wanted one so I put my name into the COPO drawing to be able to purchase one for myself. I never heard anything about winning a spot to buy one after I entered. I ended up getting a call from Chevrolet Performance but not because I won a spot. They had a guy that was selected to buy one out in California but he doesn’t want it and he wanted to sell the car. Within a few days I sent him a deposit after we made a deal and eventually I went to Michigan to pick the car up when it was done,” Brandon explains.

After Brandon made the deal to get the COPO he ran into SAM Tech’s Brian Massingill in the staging lanes at a divisional race and struck up a conversation about the car. Brandon stayed in touch with Brian as the car was built so he could get some assistance after he took delivery. With the car in his possession, Brandon leaned on Brian for tuning help to work the bugs out of the car, and also with engine assistance to make the COPO and his Oldsmobile even faster.

“Working with SAM Tech with the engine program has been great. They give me a lot of support and help to keep me racing at such a high level. They build the engines, fix them if there’s a problem, and they provide tuning help. Their tuning assistance this year has given me a consistent and fast car with the COPO that allowed me to get a runner-up finish at Atlanta,” Brandon says.

Building The Bullets

Aaron Kuhn is a SAM Tech graduate that has taken every course the school has to offer — he then became an instructor at the school. Aaron’s role is to help Brandon with his engine program while integrating the students into the build. Out of the two engines SAM Tech builds for Brandon, the 455 cubic-inch Oldsmobile mill that powers the 1972 Cutlass provided the best learning platform for the students. It’s a unique engine that challenged everyone involved to optimize it for Stock class racing.

“With the Oldsmobile engine you have to start with the block, and in particular the oiling system. The next big thing is that there’s a lot done to the ring sealing hone jobs on the engine. We did a lot of experimenting with those hones and a lot of work with Total Seal with the ring package to get it finalized. There was a lot of power to be had in that area so we paid a good bit of attention to it. From there, we got into the process of precision machining everything, making sure we had the correct deck heights and the hone jobs are good. That’s very important with these Stock Eliminator engines because they are very strict on rules and we have to squeeze every ounce of power possible out of the engine,” Aaron explains.

The Oldsmobile engine also gave the students great experience in how to work with a limited set of parts to create power. Stock class racing has some of the most restrictive rules in all of drag racing, so engine builders have to maximize what they’re allowed to use.

“We’re allowed to go with some aftermarket parts inside the engine. The pistons aren’t an original part, they’re actually a CP Carrillo part. We work with them to get the piston to our specs, but it also meets the NHRA requirements. The crank, heads, and block are stock, but we can do our own valve job on the heads. That’s what makes Stock Eliminator so competitive and makes winning those class trophies so important to the engine builders — it shows you squeezed the maximum potential out of the engine, based on the rules,” Aaron says.

After we do the instructing, the students get to do as much of the work as possible while I oversee everything to make sure it’s correct. – Aaron Kuhn.

Shawn Hoop worked with the students on the cylinder heads of Brandon’s engines. The Oldsmobile engine was originally designed to be used in trucks, so Shawn and his students had their work cut out for them when they had to try and make some power.

“Like any other engine, our cylinder head department spent a lot of time playing with valve angles and minimum chamber cc’s with the heads to meet the rules and optimize the power. We tried numerous camshafts with the engine and COMP Cams helps us out with that. We put the engine on the dyno, made some pulls, change the cam, and try it again. There was a lot of time on the dyno making changes to the camshaft,” Aaron explains.

The COPO that Brandon piloted to a fifth-place finish in the national Super Stock standings actually came to him in Stock class trim. Just because the COPO was delivered as a factory-built racecar doesn’t mean it couldn’t be improved upon. Like the Oldsmobile engine, Aaron and the SAM Tech students created a plan and went to work to help the COPO become more competitive.

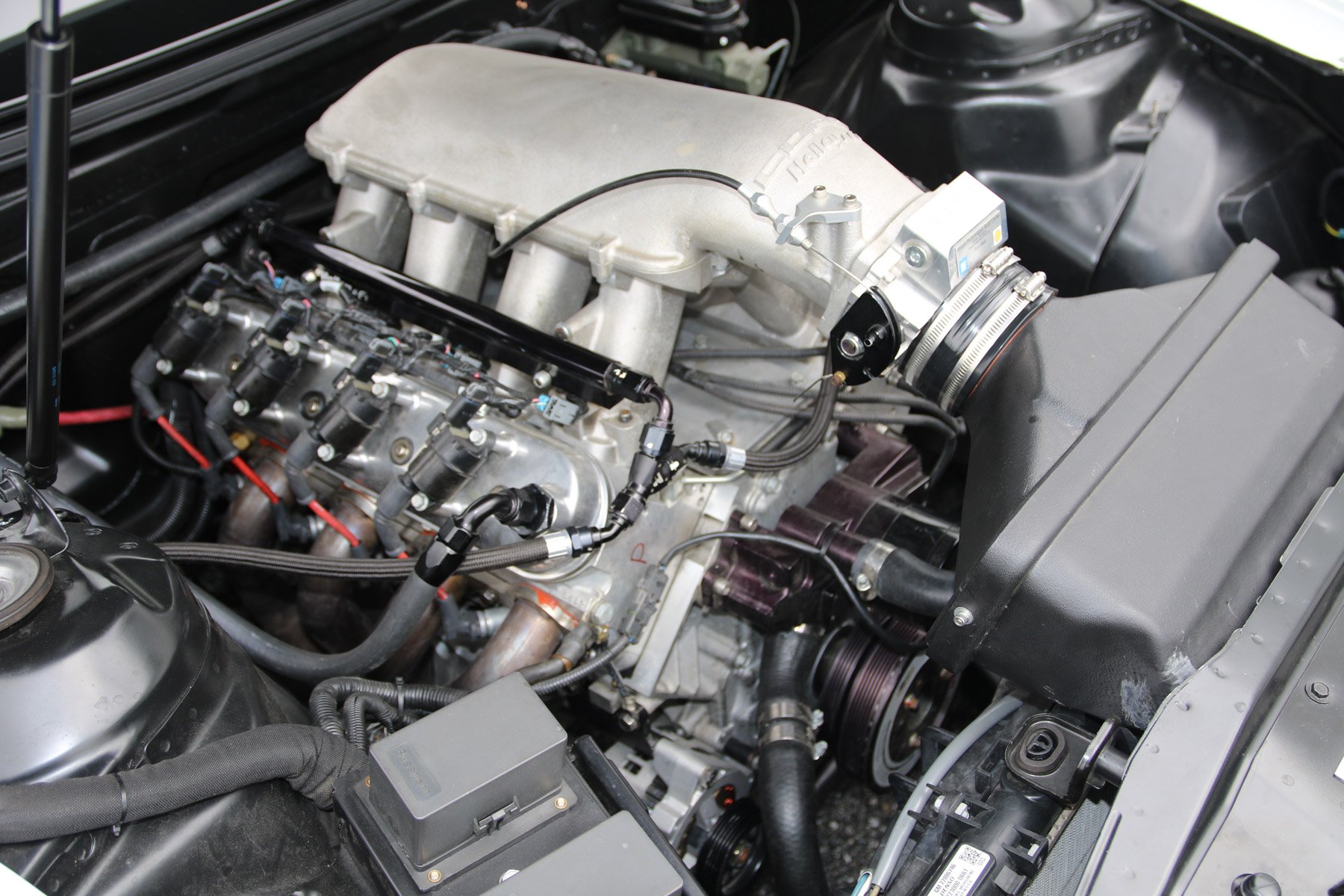

“The COPO engine is pretty much the same when it comes to development except the parts that come with the engine are already pretty good from the factory. We still have stock-style Mahle pistons and factory headers since they’re optimized well. Overall, we just had to make some small tweaks to help coax all the power possible out of the engine itself. The Holley fuel injection system makes it easier on the tuning side so those students get to play with it more on the calibration end of things. It’s still a great platform for the students to learn how to make horsepower by seeing what can be improved,” Aaron says.

Working With SAM Tech

At SAM Tech the students are a huge part of building the engines used on race day; they are really getting an education on how to build an engine so they are ready to go work for a shop or start their own after graduation. Each student is learning something in the classroom and then immediately getting to put it into practice in the SAM Tech shop with their instructors. Many of the students are even building their own project engines in the shop to learn more on their own.

“After we do the instructing, the students get to do as much of the work as possible while I oversee everything to make sure it’s correct. They get to go to events to see the fruits of their labor and some of them get to work with the drivers at the track. Everything is very hands-on and interactive while they learn. We don’t hide anything from the students as they build the engines — we don’t publish the specs, but the students can ask any question and we’ll answer it,” Aaron says.

So far Brandon has been impressed with what the SAM Tech students have brought to the table and to his engine program. He can now run at a high level nationally in both Stock and Super Stock to chase world championships.

“Working with the students is great, I mainly work with Aaron on my program. When I started working with SAM Tech he was a student and now he’s an instructor. The students they bring to the track a very sharp and very energetic. They are more than willing to help. It’s amazing how much knowledge the students have when we work with them. I’ve been around racing all my life and it seems like the students have already surpassed my knowledge base just after a little bit of time at the school.”

What Brandon has gained from working with SAM Tech and its students goes beyond the drags strip for him. The Massingills’ treat everyone like family and Brandon has seen this first hand as he’s worked with the team. This sense of family and team has enhanced his experience with SAM Tech and made racing more enjoyable.

“Jud and Linda are amazing people that spend a lot of time with you. It’s not a business to them, it’s on a personal level and they enjoy it. Judd was at the Divisional race in Houston and stayed until the end helping out. He told me what he thought I could to do help the car and it was great. Working with Brian has been fun, we work well together when it comes to racing and get along on a personal level too,” Brandon says.

Working with SAM Tech has been beneficial for both Brandon Bakies and the students who build his engines. Brandon now has the world-class horsepower for his Stock and Super Stock rides, while the students get to be exposed to new platforms to generate horsepower.