Master engine builder Ken Duttweiler (r) and ARP’s Chris Raschke (l) are shown tending to the Speed Demon’s 2,600 hp powerplant.

Story by Bill Holland

Photos by Rick Head and Chris Raschke

In all of motorsports, there’s nothing quite as viscerally awe-inspiring as the sound of a solitary racecar breaking the silence at Bonneville and streaking across the fabled Utah salt flats at speed. It’s an outpouring of raw horsepower in its purest form, propelling a vehicle to terminal velocity.

Over the years, purpose built streamliners with names like, Bluebird, Challenger, and Goldenrod have established speed marks for piston-powered vehicles that have left indelible impressions on motorsports enthusiasts. However, more recently there is only one name that symbolizes the fastest of the fast; Speed Demon.

The sleek single-engined ‘liner has propelled driver George Poteet to numerous SCTA/BNI records and captured the prestigious Hot Rod Magazine trophy for Fastest Speed of the Meet at the Bonneville Nationals no less than six times and bettered marks set by cars with up to a quartet of engines.

Driver George Poteet is all smiles after putting his name in the SCTA/Bonneville Nationals record book. He’s set records in D, C and B classes.

Recently, Poteet captured the Hot Rod trophy with a 429.099 mph blast and set the B/BFS class record at 416.511 mph (2-way average) and had a best recorded exit speed of 442+ mph. At Bonneville, cars are categorized strictly by engine displacement, with “B” covering 373 through 439 ci, Poteet has previously set records in the “C” and “D” categories.

Engine builder Ken Duttweiler (l) and ARP’s Chris Raschke (r) look on as a Bonneville Nationals official confirm’s the engine’s displacement to certify Speed Demon’s record.

Speed Demon’s performances can largely be attributed to the engine building skills of Ken Duttweiler, who has built a variety of record-setting powerplants of various displacements over the years. Noted fastener manufacturer ARP has also been an important part of the Speed Demon’s efforts, giving Duttweiler the ability to push the twin-turbocharged small blocks to outrageous levels of performance. Most are standard catalog items, with some specially made for this unique application. ARP engineers and manufactures special fasteners for builders around the globe, including many Formula 1 teams.

As you might recall, the original Speed Demon crashed in 2014, but its engine lived on to power a more svelte edition of the fabled liner; one that has the potential to eclipse the 500 mph barrier for piston-powered vehicles if Mother Nature and course conditions cooperate.

Before taking a closer look at the engine that captured the HRM trophy for 2016, consider that Speed Demon hurtles across the salt at full throttle for over a minute, and about 20 seconds of which are at over 40 psi boost. Compare that to a drag car, which is at WOT for mere seconds. It takes real stamina to go fast on the salt!

The basis for Speed Demon’s “B” engine is a Dart small block, which measures out to 388 cubic inches thanks to a 4.170-inch bore and 3.550-inch stroke. Previously, the Speed Demon has set records with 368 (4.130 x 3.400) and 300 (4.135 x 2.800) cubic inch displacement engines.

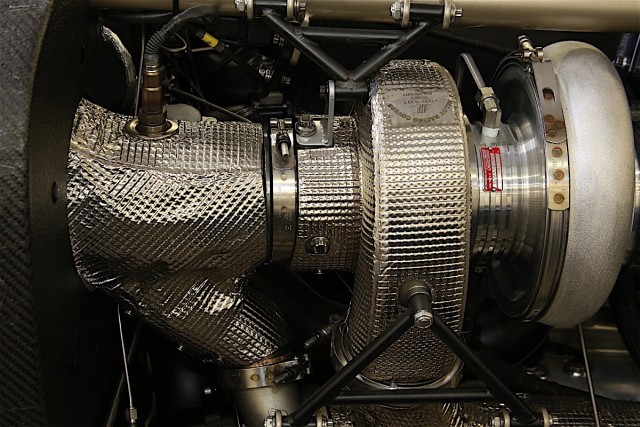

A Crower crankshaft and connecting rods (equipped with ARP Custom Age 625 Plus bolts), Diamond pistons and Total Seal rings comprise the rotating assembly, with an ATI Super Damper maintaining the critical high-speed balance. The static compression is 9.2:1, while a pair of Pro Mod 88 style turbochargers from Precision Turbo up the combustion pressure with a boost range from 11 to 42 psi.

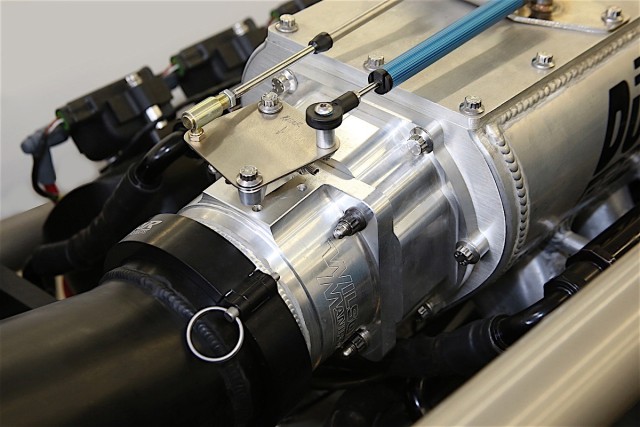

A Wilson throttle body is mated to a custom Hogan intake manifold to feed the appropriate air/methanol mixture to the 388 ci engine.

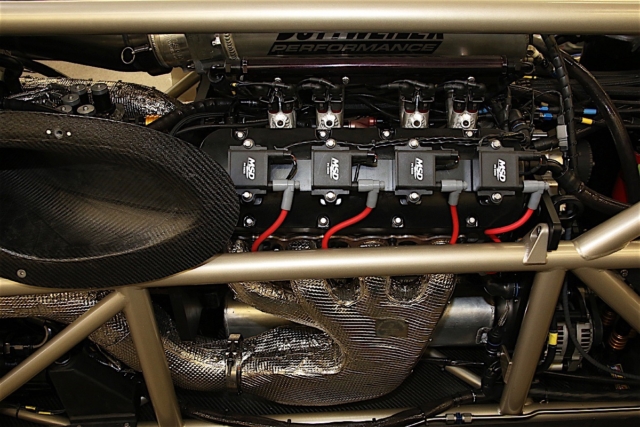

Dart “Little Chief” cylinder heads, which have been fully CNC ported, and embellished with Jesel shaft rocker arms, Ferrea valves and PAC valve springs & retainers sit atop the block, with a Hogan fabricated aluminum intake manifold and 105 mm Wilson throttle body atop that. A load of VP methanol is fed to a battery (16) of Siemens fuel injectors that are rated a 225 pounds, with a set of Enderle injectors activated mechanically when power levels in excess of 2,400 hp are desired. A Waterman mechanical fuel pump provides up to 130 psi pressure.

The CNC-ported Dart “Little Chief” aluminum heads are guided into place and secured via ARP head studs.

ARP head studs made of Custom Age 625 Plus material keep the heads clamped tightly to the block, which has been grooved for O-rings (with matching receiver groove in the head) and employs SCE solid copper gaskets.

Maxwell Industries is responsible for fabricating the intercooler and plumbing it, while they also built the Speed Demon’s headers.

Lubrication for the 2,660 HP engine is handled by an Aviaid dry sump system, which pushes Lucas oil to all the necessary places and evacuates the Billet Fabrication pan. Engine speeds range from 3,500 to 9,500 RPM. Brown and Miller hoses and fittings take care of the plumbing. The power is fed to the transmission via a Crower clutch, with a Browell bellhousing providing the connection (and safety).

The Speed Demon’s exhaust system was created by Maxwell Industries. Also shown are MSD ignition components and the Siemens fuel injectors.

Needless to say, coordinating the valve train and intake system events is critically important. Inside the engine, a Comp roller cam with Jesel keyed lifters and Trend pushrods control the valve train, while Motec/M&W CDI boxes, plus MSD coils and wires handle igniting the Champion spark plugs.

And given the salt’s propensity to “eat” most anything metal, the Speed Demon team has put ARP polished stainless steel fasteners, which are nealry impervious to rust and corrosion, to work everywhere possible. They are also significantly stronger than Grade 8 hardware.

While the current “B” powerplant pushes out 2,660 horses and 1,600 lb-ft of torque, it should be noted that the small “D” engine (300 ci) cranked out 2,200 ponies and 1,200 lb-ft of torque. That calculates to 6.85 and 7.33 horsepower per cubic inch respectively — quite an impressive number!

With enthusiast-based organizations like Save The Salt and SEMA, bolstered by public opinion, fighting to bring the salt flats back to its former glory (the available racing surface is greatly diminished thanks to unchecked, aggressive potassium mining in Tooele County) it’s hoped that racers can continue to test their mechanical mettle in the years to come. Bonneville is an “engine lab” of the highest order, and the Speed Demon team hopes to make the most of it.