When it comes to the engine in your car, one thing is certain; parts are going to wear, and eventually wear out. One of the most important items in your engine that you really want to keep from prematurely wearing out, or failing altogether, are the bearings. We all know what the bearing’s job is, but what makes a bearing strong enough to survive the beating that it receives when the engine is running?

Bearings must be constructed of materials that will not only withstand the abuse of the running engine, but they must also be able to support and protect rotating parts without scoring, burning, or falling apart. What it comes down to, is construction. Engine bearings are made of materials that when combined, result in an “alloy” that is able to survive these conditions.

Engine bearings are typically made in either bi-metal, or tri-metal configurations. Bi-metal bearings are built with a steel backer that supports the bearing structure, and provides rigidity for the bearing. The second layer is the actual bearing material which is roughly .012-.015-inch thick. The thickness is a very important feature of bi-metal bearings, as it is designed to accommodate slight bearing face misalignments and other irregularities. It also provides good embedability for unwanted dirt and debris that gets carried through the engine via the oil. This lining is commonly made of an aluminum alloy that contains anywhere from 6 to 20-percent tin content. Another additive within this lining is silicon. There is anywhere from 2 to 4-percent of silicon that is dispersed in the aluminum. Having silicon is important, especially for engines that are using cast crankshafts.

Engine bearings are typically made in either bi-metal, or tri-metal configurations. Bi-metal bearings are built with a steel backer that supports the bearing structure, and provides rigidity for the bearing. The second layer is the actual bearing material which is roughly .012-.015-inch thick. The thickness is a very important feature of bi-metal bearings, as it is designed to accommodate slight bearing face misalignments and other irregularities. It also provides good embedability for unwanted dirt and debris that gets carried through the engine via the oil. This lining is commonly made of an aluminum alloy that contains anywhere from 6 to 20-percent tin content. Another additive within this lining is silicon. There is anywhere from 2 to 4-percent of silicon that is dispersed in the aluminum. Having silicon is important, especially for engines that are using cast crankshafts.

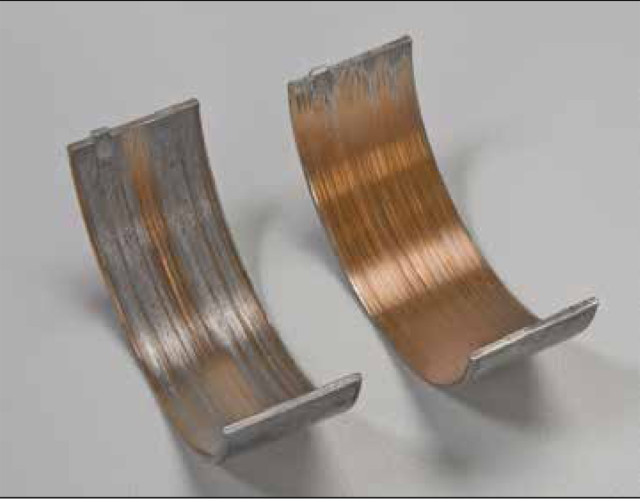

When was the last time you changed the oil in your engine? This bearing shows what happens when you don’t. Letting the old, dirty oil remain in your engine, will wear on the Babbitt material, eventually exposing the copper intermediate layer. By not changing the oil in your engine, you are inviting premature bearing failure.

Tri-metal bearings have an added intermediate layer that is usually made of a copper alloy coating. This coating is developed with anywhere from 20 to 25-percent lead. This lead acts as a solid lubricant, and then 2 to 5-percent tin is infused, which is used to add strength. Finally, there is a third layer. This is a lead-based overlay (Babbitt material) that is applied over the intermediate layer. This lead-based alloy contains a small percentage of tin and copper that adds strength and lubricity.

That was enough talk about how bearings are made. What we want to educate you guys about, is bearing failures. We found this video that the guys at Mahle put together, and thought you guys might enjoy it. It gives some insight into why bearings fail. The video is just slightly longer than three minutes, and is really worth watching. Also, you can click here for downloadable pdf file explaining bearing failures with images.

If the surface of your bearings look like this, it is an indication of overloading, which could be caused by either detonation or the use of a standard-service bearing in a high performance application.