One of the biggest engine swap issues that enthusiasts have faced for decades is working the exhaust system around accessories, steering shafts, and the frame. Ultimate Headers hit SEMA with the intention of solving that issue once and for all. The company was launched earlier this year by well-known exhaust specialist, Jim Browning, known throughout the aftermarket industry as the founder and past president of Corsa Performance.

One of the biggest engine swap issues that enthusiasts have faced for decades is working the exhaust system around accessories, steering shafts, and the frame. Ultimate Headers hit SEMA with the intention of solving that issue once and for all. The company was launched earlier this year by well-known exhaust specialist, Jim Browning, known throughout the aftermarket industry as the founder and past president of Corsa Performance.

“For years, enthusiasts and racers have been faced with this problem of wanting something different for a powerplant in these cars and trucks, but have been struggling to find a workable solution to the header problem,” says Browning. Oftentimes cutting and rerouting the headers or placing dimples in areas of contact to get the header to fit is the resort but these options compromise the durability of the exhaust system.

Browning sought to address three main issues with the development of his exhaust system – optimizing materials using current accepted engineering and design standards and practices, creating an exhaust system that could fit inside tight physical envelopes in the engine compartment, and providing an eye-catching system without hindering the clearance or strength.

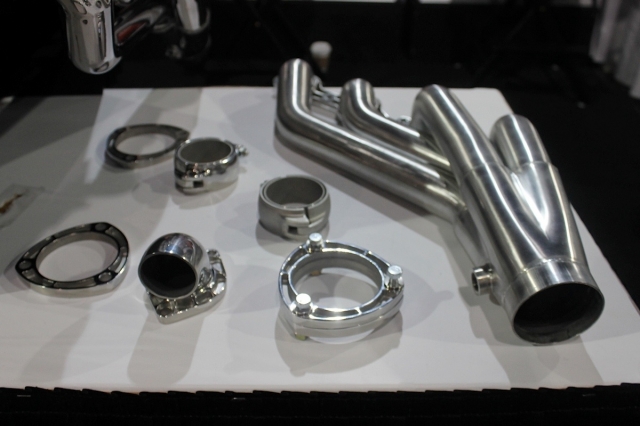

The design team utilized a process known as Finite Element Analysis (FEA), which uses a computer to evaluate the CAD (computer aided design) drawings and metallurgical attributes of various metal alloys being used. This is a process used in both the aerospace and OEM automotive markets. From the results an all-stainless steel header, one which uses cast stainless steel head flanges and investment cast elbows was chosen.

The design team utilized a process known as Finite Element Analysis (FEA), which uses a computer to evaluate the CAD (computer aided design) drawings and metallurgical attributes of various metal alloys being used. This is a process used in both the aerospace and OEM automotive markets. From the results an all-stainless steel header, one which uses cast stainless steel head flanges and investment cast elbows was chosen.

Because the traditional method of mandrel bending tubing is limited by the diameter of the tubing, meaning a two-inch diameter tube can only be bent to a two-inch radius before folding occurs, Browning opted for cast elbows which allows the turn to be tighter. Consequently, the header envelope is pulled tight against the head and block allowing for larger tubes to be placed in tight places.

The combination of cast flanges and elbows allows for a more customizable approach to building the headers. Elbows can be positioned within the flange as desired before being welded allowing for a modular system. According to Browning, “We offer the modular flange-elbow system to meet those needs for the GM LS-series engine and with our new headers for the GM Big Block engine family. This will be a feature for every engine family which we will supply headers.”

The collector flange was another area of improvement for Browning, “We saw the flange to mate the header and the downpipe to be lacking aesthetically. We designed a couple of collector flanges which carry the same ribbing design of the head flange delivering a collector flange with eye appeal, strength, and light weight.” Ultimate Headers offers the collector flange in two forms: a 3-bolt straight connector flange and a 3-bolt ball-style flange.

Using 316L stainless steel casting, the same grade used in the head flange, cast elbow, and collector flange, Ultimate Headers fabricated a detachable two-piece collector connection clamp with a claw style hinge that uses a 5/16-inch stainless bolt to connect and clamp.The clamp’s design allows a 10-degree range of flexibility to be able to connect the pipes in a difficult installation while maintaining a no-leak seal.

The Ultimate Header Total Pakcage

The Ultimate Header Total Pakcage

Along with all these eye-catching components Ultimate Headers includes everything that the enthusiast needs for installation. “We realize this is a premium level header product,” says Browning. “We have included premium level fasteners, the exhaust gaskets, and choice of collector flanges in the box.”

Buyers can choose from three different finishes for the headers – vibratory polished, mirror polished, and satin finishes. On top of that, Ultimate Headers also offers a high temperature ceramic coating finish that withstands up to 1800 degrees fahrenheit.

Browning and his team came to SEMA with a product that was aimed at addressing some key issues during engine swaps – a header that makes use of the most durable and well engineered materials, showcases a design conducive for limited space within the engine bay, and looks like fine crafted jewelry. Ultimate Headers stands as a problem solver in the industry making the enthusiast and the racer’s life easier by providing a quality product that looks just as good.

For more information on Ultimate Headers and their product, visit their website here.