Over the last eight years, since the debut of the modern-day Cobra Jet race program, Ford Performance has continued the innovation of this trend-setting product lineup — and just moments ago, they released the details on the 2016 variant of the factory-built race car at the SEMA Show in Las Vegas.

With the debut of the all-new 2015 Mustang, the Ford Performance Team went back to the drawing board to create the powerplant that will power the limited run of 50 units; the first-anywhere details are right here in this post.

“We are committed to supporting Sportsman drag racing and in NHRA Stock, and that means delivering a Cobra Jet the teams can be competitive with from the factory. Beyond that, it needs to provide the platform for them to take its performance to the next level,” says Jesse Kershaw, Ford Performance’s Drag Racing Parts and Competition Manager.

The Coyote engine has proven itself in many race classes and events, and the Cobra Jet’s engine program was developed to showcase factory-built parts.

“It was important to use production hardware wherever possible in the engine to ensure parts are readily available and reasonably priced for racers,” says Kershaw. “The production parts are also incredibly durable in passing our rigorous dyno and drag strip testing.”

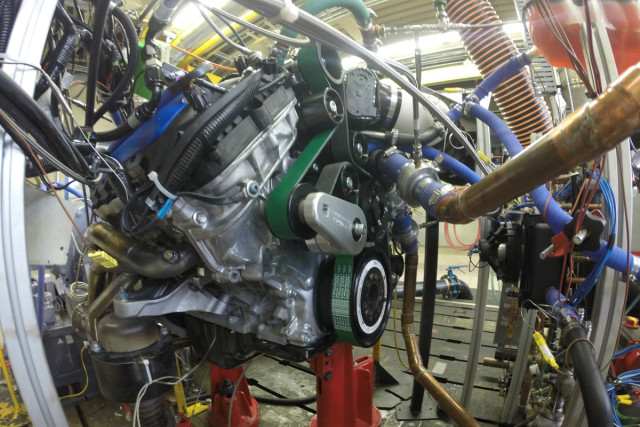

Wondering what type of testing the Ford Performance team has done with the engine platform? Thanks to the availability of incredibly sophisticated simulators — and world-renowned Milan Dragway in close proximity to Dearborn, Michigan — engineers tested the platform in-house at the Ford Essex plant’s development dyne to exercise precise control over testing, then proved out their simulations on the drag strip.

Wondering what type of testing the Ford Performance team has done with the engine platform? Thanks to the availability of incredibly sophisticated simulators — and world-renowned Milan Dragway in close proximity to Dearborn, Michigan — engineers tested the platform in-house at the Ford Essex plant’s development dyne to exercise precise control over testing, then proved out their simulations on the drag strip.

“We program the cell to replicate a quarter-mile run exactly including the burnout and staging and make over 100 passes, then tear the engine down for inspection before the engine ever goes into the car for on-track testing. We then make another 100 passes in the car with the same engine and tear it down again to verify,” Kershaw explains.

The thought process behind this engineering effort is to provide racers with a platform that’s been sorted out, is expected to give a solid showing on the racetrack, and provide some measure of durability.

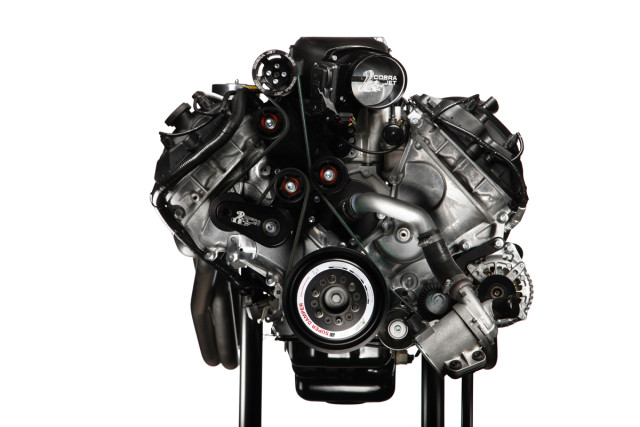

Owing to the consistency realized through the development stages, Ford Performance engineers source more than 75-percent of the Cobra Jet’s engine components right off the shelf — the same parts that appear in street-going Mustangs and in the Ford Performance catalog.

“In developing the engine we partnered with several of the drag racing industry leaders such as ATI, Aeromotive, and Whipple Superchargers. But the heart of the engine is production based with over 75 percent of the content common with the Mustang GT engine. Beyond that, the rods, pistons, and oil pump are identical to what’s used in all of our boost-friendly Aluminator crate engines. Production hardware is readily available at any Ford dealer, is very cost effective, and has proven to deliver performance,” says Kershaw.

The 2016 version of the Cobra Jet’s engine is based around the 5.0-liter V8 engine platform that displaces the same 302 cubic inches in the Cobra Jet.

The Cobra Jet is not just built, it’s engineered, which means validation and testing that ensures reliable, repeatable performance. – Jesse Kershaw, Ford Performance

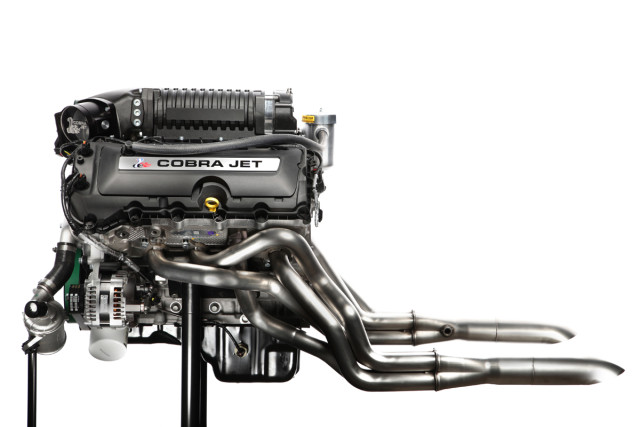

The Cobra Jet engine, drawing from the proven Aluminator crate engines, uses forged pistons from Mahle, which also incorporate the company’s Grafal coated skirts for friction reduction. Forged H-beam connecting rods from Manley are standard equipment, secured by ARP 2000 capscrews.

American Racing Headers stainless steel pipes remove the exhaust from the engine, and Aeromotive’s fuel rails along with ATI’s SFI-approved Super Damper are also on board.

The 2016 version of the Cobra Jet uses the now-familiar Whipple 2.9-liter supercharger on top. It’s interesting to note that this year the boost-maker is configured in front entry form, which we suspect is due to the hoodline limitations of the new body. There is a jackscrew that takes the motion transmitted by the drive pulley, located next to the throttle body, and transfers it to the supercharger’s drive gears in the rear of the supercharger near the firewall.

With the power of the factory’s software developers at their fingertips, the Ford Performance Team also puts together proprietary engine control software and calibrations for the Cobra Jet program.

One other eye-catching change made for the 2016 version of the factory race car is the use of an electric water pump. Previous versions used a mechanical version. The part — an off-the shelf unit — comes from the C-Max hybrid vehicle, of all places.

“The electric water pump is something we’ve held off on in the past because we were concerned with durability. Not only is it able to cool the car back down to ambient temperature within 15 minutes between runs, it has been durability tested on a production street car,” says Kershaw.

Putting together a package like the Cobra Jet that continues to excel year in and year out, despite vehicle platform changes and other requirements, is no small feat for the Ford Performance Team.

“The modern Cobra Jet has performed for our customers and put Ford in the winner’s circle consistently since 2008,” says Dave Pericak, director of Ford Performance. “This is the only factory 2016 Mustang with a solid axle rear suspension, and the first Cobra Jet built off the all-new Mustang introduced in 2015. We are excited to see it compete.”

There will be 50 units built, with 25 covered in Oxford White and 25 in Deep Impact Blue. The only available options are the Cobra Jet graphics down the side of the car, and a single-wheel wheelie bar configuration. Pricing starts at $99,990. Production is underway with delivery expected in the first quarter of 2016, just in time for the upcoming racing season.

“The Cobra Jet is not just built, it’s engineered, which means validation and testing that ensures reliable, repeatable performance,” sums up Kershaw.