TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Thor Schroeder, national sales manager at Moroso.

TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Thor Schroeder, national sales manager at Moroso.

EngineLabs: How has in-pan oil-control strategies changed in the past 20 years, including working with new crankshaft designs?

Schroeder: If we are designing an oil pan for a specific application and don’t anticipate that we would coming out with different versions of the oil pan, from the start we would design the oil pan with road-race baffling. Road racing puts acceleration, cornering and de-acceleration demands on the oiling system. For drag racing, then, the aspects of acceleration and de-acceleration are covered. We recently released a first-of-their-kind line of small-block Chevy oil pans based on a Moroso-exclusive stamped-steel core. They’re stock appearing but will take up to a 4.125-inch stroke and fit Dart, GM and Merlin 4-bolt blocks. Material wise, Moroso is moving away from folded-over or double-thick sheet-metal rails towards thick laser-cut steel rails and seals on the steel oil pans. On our aluminum oil pans, we’re staying with billet aluminum rails but having billet aluminum seals where needed.

EngineLabs: Attention has been focused on drawbacks of the oil system of the LS engine. What is Moroso’s evaluation of that platform and its strategies for improving engine lubrication?

EngineLabs: Attention has been focused on drawbacks of the oil system of the LS engine. What is Moroso’s evaluation of that platform and its strategies for improving engine lubrication?

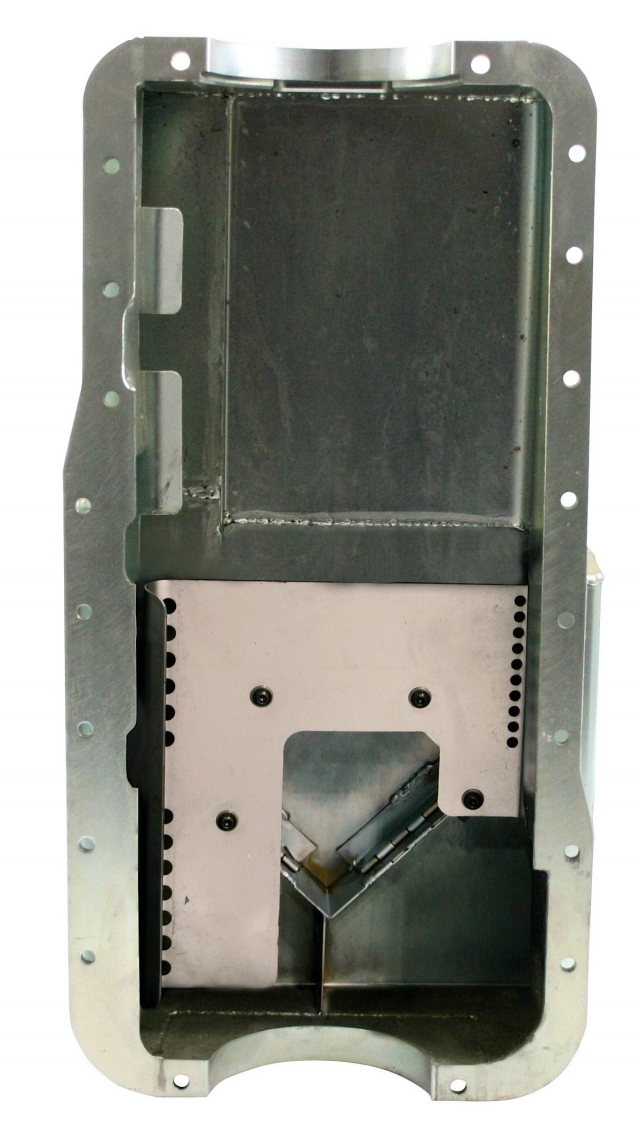

Schroeder: First, our company supports the LS platform. Two examples are the LS oil pans we introduced at the 2012 PRI Show. Both are fully fabricated steel pans featuring a thick laser-cut steel rail, clear zinc finish and a diamond-shape, 4-trap door assembly with anti-slosh baffle to keep oil contained in the pick-up area during road and drag racing. Also, they have a billet aluminum adapter that allows a 13/16-inch-thread Moroso or OEM oil filter to be mounted in the stock location — no need to run a remote oil filter. The difference between the two oil pans is the depth of the front of the oil pan: one has a deeper front for clearance for use of our main-cap-mounted windage tray. Moroso is also developing prototype parts and supplying production parts to Dart Machinery for its LS Next engine program.

EngineLabs: How does an air-oil separator work, and is it more beneficial to racing engines or street engines?

Schroeder: Yes and Yes, beneficial to both types of engines for the same and different reasons. In race engines they are used for the separation of air and oil in dry sump and vacuum pump systems. In non-dry sump or non-vacuum pump equipped engines a properly designed air-oil separator is a component in stopping oil smoke and oil mist from an engine compartment. In street engines they are beneficial because they help make the factory systems more efficient and work better while maintaining emission compliance by keeping the system contained. Due to emission regulations, vehicles from the factory vent these excess crankcase vapors, residual oil mist and moisture right back into the intake manifold — which could cause detonation, oil deposits to form in the intake tract including the valves themselves and from lowering the efficiency of the intercooler, if so equipped.

EngineLabs: What is an oil accumulator?

EngineLabs: What is an oil accumulator?

Schroeder: An accumulator is a high-pressure oil storage tank that supports a movable billet-aluminum, double O-ringed piston inside. There is pressurized air on one side of the piston and engine oil on the other side. The oil side of the accumulator is connected into the engine’s oiling system. When engine experiences a fluctuation in oil pressure, the accumulator provides an instantaneous supply of oil to the engine. When the danger is over and the oil pump is once again primed with oil, the engine’s oil pressure forces this reserve of oil back into the accumulator. Moroso accumulators require just one oil line to the engine, and it can be T’d into the return line of an oil cooler or remote filter, or it can be routed into an oil galley on the pressure side of the engine’s oil system. There are different types of valve systems to initiate the oil supply, including a manual valve and two type of optional electric valves.

EngineLabs: For which applications is it most beneficial?

Schroeder: All competition engines where there’s a chance of oil flowing away from the pickup, such as hard acceleration or cornering, or in severe off-roading where the vehicle is off camber much of the time. But also for street engines. Independent tests have shown that 85 percent of engine wear in street cars is caused by “dry starts” of an engine. The accumulator can prevent cold-start scuffing by pre-oiling the engine before startup. Moroso offers standard and heavy-duty accumulators, depending on the intended use.