TECH5 is a regular feature where EngineLabs asks industry leaders five technical questions. This week’s guest is Steve Rhodey, Manager with TREND Performance. Steve was exceptionally forthcoming during our discussion, so we doubled up with ten questions to provide you, dear reader, with as much information as possible.

EngineLabs: Can you give us an example of your most popular pushrod choices? Are there different materials to chose from in addition to diameters?

Steve Rhodey: “As far as quantities are concerned, the .080-inch wall line in 5/16-inch and 3/8-inch diameters are the largest volume TREND manufactures. The numbers come in at approximately 15,000-18,000 pushrods per day, but when we discuss the popular parts for the more serious setups our stocking lines of the double taper 7/16-inch .165-inch wall and 1/2-inch .200-inch wall have been booming. When it comes to professional racing of all forms we produce a large number of 1/2-inch, 9/16-inch, 5/8-inch and we have even been working on several wall thicknesses in a 3/4-inch diameter. All of our pushrods are offered in a few different wall thicknesses, but it seems everyone is catching on to the bigger is better theory which we have found to be pretty accurate.”

EL: Are there guidelines for matching pushrod diameters to spring pressures?

Rhodey: “Yes, there are guidelines for what pushrods will take in regards to spring pressures. The rule of thumb is to run the biggest pushrod you can fit in the motor. Typically the diameter of the pushrod tube relates to the spring pressure, RPM and expected cylinder pressures under various applications. 5/16-inch and 3/8-inch .080-inch wall pushrods are generally street use applications. Larger diameters are used for various racing applications, with a 7/16-inch heavy wall being needed as a minimum for spring pressures greater than 1,000 psi. Now while these rough gauges do help, they do not take into effect boosted applications where spring pressure isn’t the only load the pushrod will see. In a high horsepower application with power adders cylinder pressure on the exhaust side can be greater than the spring load. That is to say that the pushrod has to push the valve open into the combustion chamber against severe pressures many times greater than the spring pressures. This can mean that a 9/16-inch pushrod is needed in a motor with 1,200 psi spring pressures.”

EL: In what engine applications is the V-cup/ball adjuster system advisable over a standard arrangement?

EL: In what engine applications is the V-cup/ball adjuster system advisable over a standard arrangement?

Rhodey: “Engine builders typically go to a ball style adjuster when the valve train geometry becomes so extreme that oiling between the ball on the pushrod and cup adjuster becomes impractical. No oil is able to ride on the ball and thus galling occurs. The cup style pushrod and ball adjuster allow oil to pool and flow through the area allowing the oil to cool both surfaces in these applications where gravity is pulling the oil down and away from a traditional ball push rod.”

EL: What kind of pushrod life will a high end racing application get? When does Trend recommend changing pushrods, or at the very least, what do you look for in terms of maintenance/wear?

Rhodey: “If you have to remove the valve covers, take a look at the pushrod tips and check the lash. Things to look for are ball tip deformation, excessive wear on the lifter end of the pushrod, signs of galling in the adjuster and excessive heat in the pushrod. True high end racing teams can inspect their pushrods after every race. Normally, the life expectancy for a Trend pushrod is the lifetime of the engine barring other mechanical failures.”

Various pushrods all lined up awaiting heat-treating.

EL: Does Trend have any other recommendations, guidelines, or other upgrades recommended in an application that uses 9/16 pushrods-inch like this. i.e., roller cam bearings, larger cores, etc.?

Rhodey: “We offer many different sizes and styles of pushrods for all applications. We do so many different types of pushrods from 9/16-inch diameter to larger 5/8-inch and 3/4-inch pushrods in order to work with each engine builder’s specifications. However, we do recommend good quality oil from the likes of Driven, LAT or Champion be used in all applications. What we have seen over the years is that poor oil contributes to the vast majority of pushrod failures.”

EL: What about pushrod angularity? How critical is it to keep the pushrod vertical? What about offset lifters vs having some angle in the pushrods?

Rhodey: “Pushrod geometry has always been something to be taken into consideration, let’s be honest. Sharp angles are NO GOOD. Especially with today’s camshaft build abilities where everyone is running a 1-inch cam (so it seems). You can imagine what that does for angularity. In a perfect world for pushrod functionality, one would love to keep that pushrod as vertical as possible, but again that would be perfect world and the one we live in is far from perfect. As far as the offset lifters are concerned, we have a lot of customers running all different styles and do not see a cause for concern either way. It’s still all about the ‘right combination’.”

Different styles of pushrods offered by TREND.

EL: What’s the story with the Spintron?

Rhodey: “Trend Performance is the creator of the Spintron machine. Similar to a dynamometer, it spins an engine to find deflection and weak parts in the valvetrain and digitizes the data onto a computer screen. TREND pushrods were engineered to fix valvetrain deflection. Our diameters and wall thickness along with shape/style are all purpose driven to offer the strongest pushrod available. We have countless victories in professional racing of all forms for many years.”

EL: Does Trend offer other products, and what else might be a good fit to keep someone in the Trend line beyond pistons? Like lifters, other valvetrain components, etc.

Rhodey: “We offer a full line of stocking and custom pushrods with options for “quickship” along with four lines of wrist pins, in 4130 chromoly, H13. M2 and the all new heavy hitter TP1 materials. We also manufacture M2 tool steel Flat tappet lifters, DLC coated rocker shafts for the modern HEMI, Valve Locks, Lash caps, HEMI tube seals, Cummins diesel flat tappets with or without DLC coating. We have an in house racing oil warehouse where we offer Driven, Champion and LAT racing oils and on top of all that we are a fully capable, state of the art machine and engineering shop. We are constantly trying new things to manufacture and improve.”

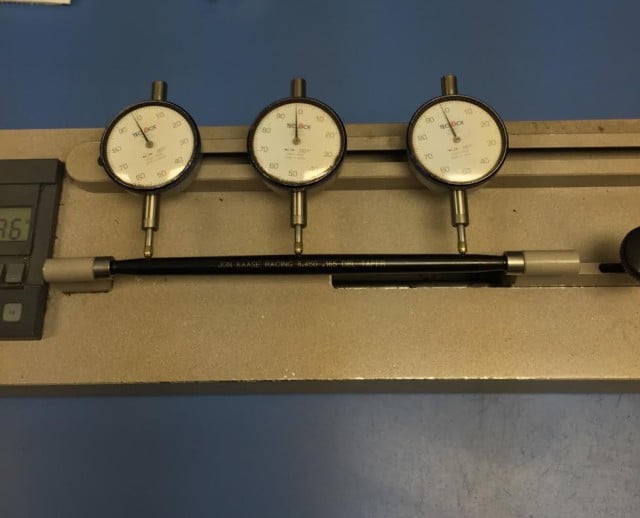

EL: How do you properly check to see if a pushrod is straight?

Rhodey: “Pushrod runout has always been checked while holding the pushrod on centers with a triple dial indicator setup measuring to .005-inch. We hold the pushrod, zero the gauges, and manually spin the pushrod to check for straightness.”

EL: When you have a pushrod failure, how do you diagnose the cause for it? Valve bouncing, valve springs, spring loads, etc? Where do you start?

Rhodey: “I’d say the popular causes for pushrod failure is excessive heat or basic overloading. There are so many potentials here it really is a case by case basis. We would start by researching the build, spring pressure, RPM, pushrod length, materials used for the adjuster and pushrod tip, engine oil, type of racing , etc., and go to work from there. The damage caused by valve bounce, poor valve spring and spring loading will pretty much look the same as a pushrod that was run without oil. At the end of the day all we can do is offer the best pushrod for the builders setup based off of the knowledge learned over the past years to ensure they are running the best combination for the specific application.”