If you hadn’t heard, snowmobiles can run low-7-second quarter mile times at over 180 mph. Yes, they run on asphalt and they also scream on the dyno.

Jeff Simon [1] is a well-known builder and tuner of uber-performance snowmobiles. This particular setup is based on a 2006 Yamaha Apex GT, which sports a motorcycle-inspired 998cc 4-cylinder, 4-stroke engine with EFI and liquid cooling from the factory.

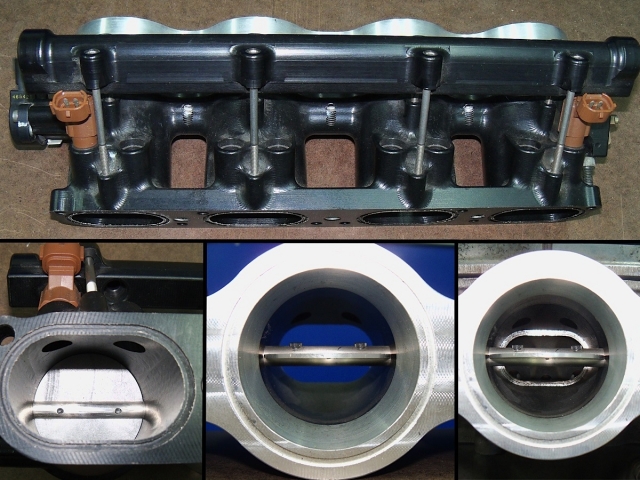

Different views of a 550-horsepower race engine prepared at Simons' shop. This engine powered Shannon Disch to 171mph on ice.

On the left is a comparison of a stock open-deck block and one that has been closed for high-boost applications. Right photos shows a stock head compared with a fully CNC-ported, big-valve version.

“I took off the EFI and throttle bodies and put on the heads and carbs from an earlier RX-1 engine and also a MSD MC4 ignition,” explains Simon, whose shop is based in Wisconsin.

Simon then hooks up a Garrett 2860 turbo up front and close to the engine, as opposed to other kits that bolt to the factory exhaust at the end of the body tunnel.

“It gets cold back there, and a turbo thrives on heat and pressure,” explains Simon, noting that he does have to replace the fuel tank and install a heat shield with his design. “When the turbo sits on the back it get hits with snow, and the inlet filter for the turbo can get clogged with snow dust.”

Typical trail setup will provide 12 pounds of boost, but if there’s some weekend racing on the schedule, the turbo can be turned up to around 29 pounds with race gas and get 400+ horsepower at 10,000 rpm.

“It’s the best of both worlds,” adds Simon.

Left photos are different turbo header designs, and on the right is a comparison of stock inlet ports and those with CNC machining.

[12]

[12]For high-performance EFI, Simon goes with a modified manifold that includes billet throttle bodies.

For a full-race engine, Simon will weld the stock crank and regrind it for a 4mm increase in the stroke. He then goes with custom Carillo rods and Wiseco 10:1 pistons. He offers two options with the unique 5-valve cylinder heads: full CNC port program or modifying the chamber around the valves and cutting new valve-seat angles.

“There’s no porting but just by manipulating the valve seats you can pick up quite a bit of airflow with the stock Yamaha head,” says Simon, adding he uses a stock RX-1 cam. “The factory Yamaha cams are pretty good.”