Total Seal Piston Rings [1] planted its roots in 1967, when Joe Moriarty Sr. introduced a rotary engine design that was intended for original equipment manufacturers (OEM). Soon after, Moriarty invented the gapless piston ring design to increase cylinder pressure and performance, along with improved fuel economy; and since that time Total Seal has spearheaded many of the biggest breakthroughs in piston ring design.

Today, Total Seal’s products can be found supporting the slugs of weekend track warriors, stock cars, open wheel racing, and drag racing builds, and are also used in the shops of engine builders for teams in NHRA, IHRA, IRL, and Formula 1. [2]

[2]

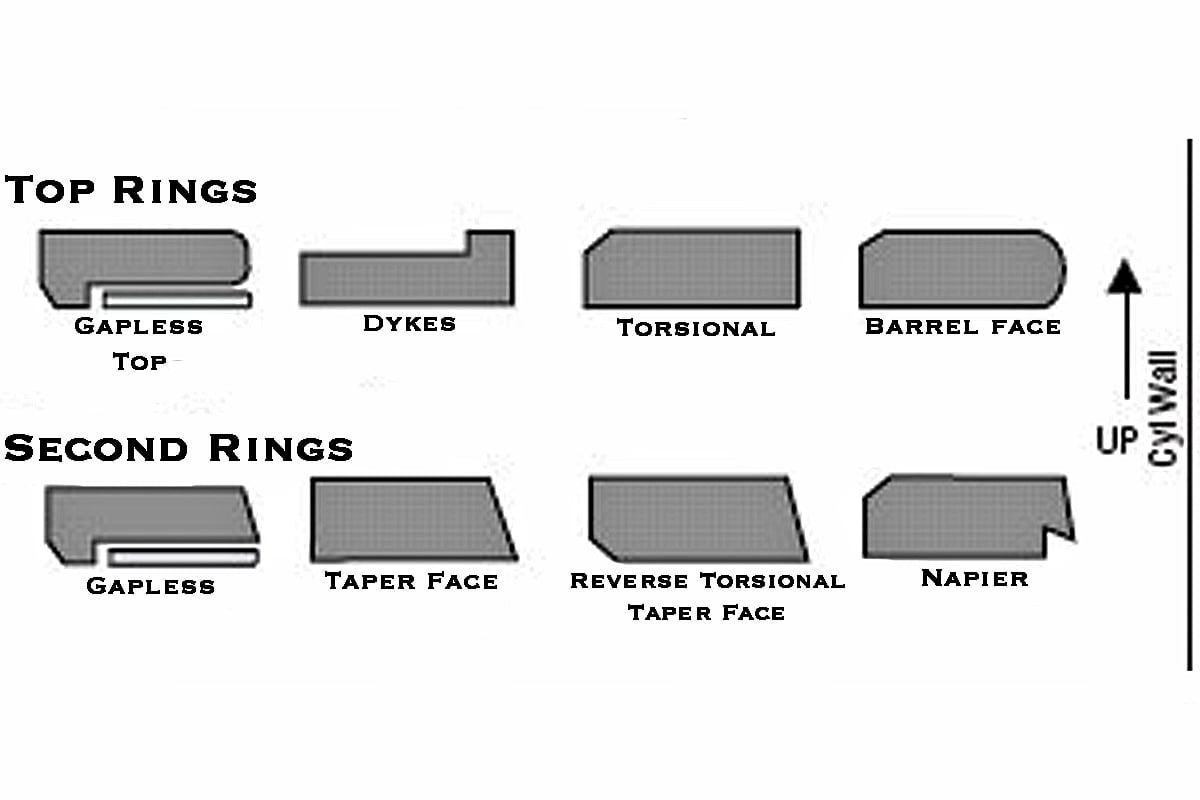

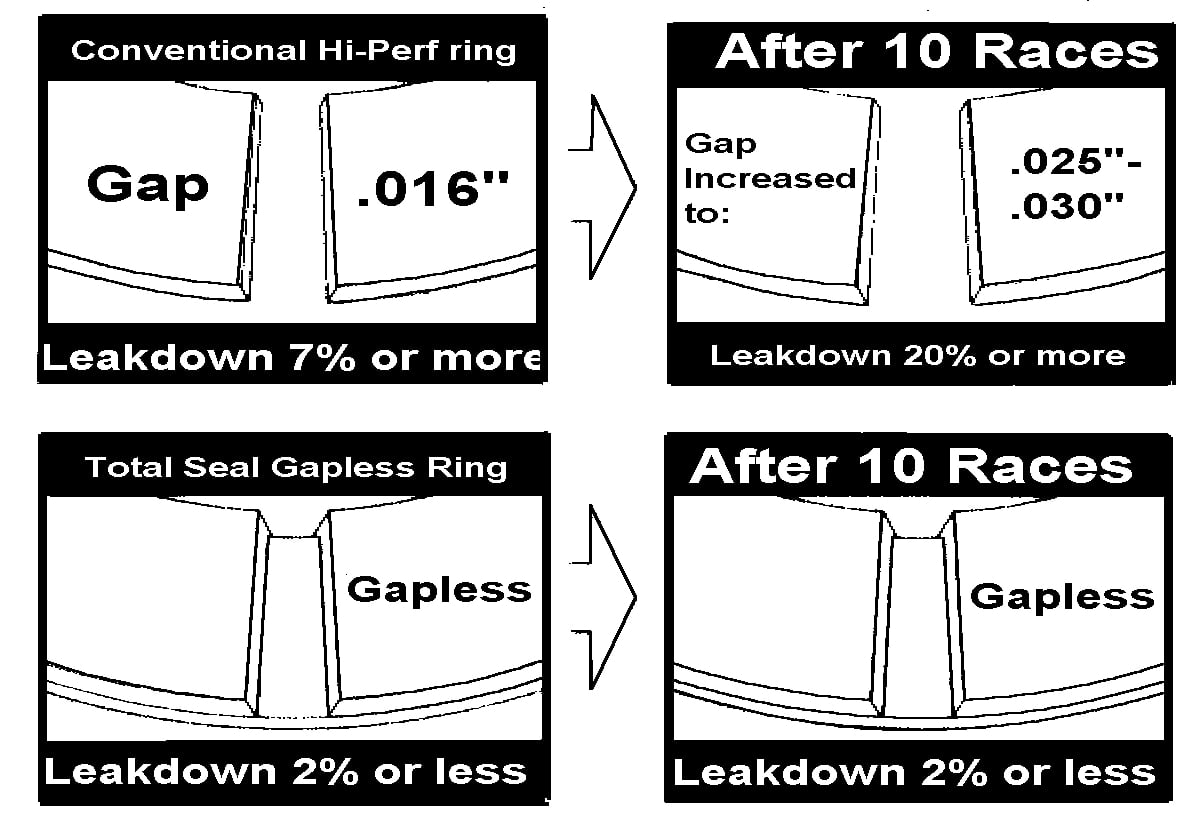

The company’s Gapless piston rings are designed to increased performance by improving the sealing of each cylinder — increasing cylinder pressure (horsepower) and more effectively preventing combustion gasses from escaping into the crankcase as blow-by. The added rail that actually makes the ring gapless is first responsible for blocking off the combustion gas leak path found in the ring end gap of standard piston rings, secondarily the rail also redirects the combustion gases into the ring groove to further assist in pressure loading the ring.

The M-series top ring set also includes a napier “hook groove” style second ring to improve oil scraping; and three-piece “flex vent” style oil ring available in 2 mm, 3 mm, 3/16-inch, and 4 mm sizes and in tensions from 6 pounds up to 27 pounds. Total Seal is also able to custom design a gapless ring kit for you application by filling out their online request form [3].