Barry Rabotnick and the team at Survival Motorsports have been competitors at the Engine Masters Challenge for years; the company specializes in the Ford FE platform and is in fact one of the industry’s go-to sources for hot rod parts for the engine design.

The FE platform is not always looked upon highly by enthusiasts, as a typical big-block Ford can be built for less money with more power. But for those FE purists, who must have an FE between the fenders of their Thunderbolt or other ’60s Ford hotrod, the FE is the be-all, end-all.

This year’s EMC was divided into five classes; the fifth day saw the big-block class where Survival Motorsports’ third-place 482-cube engine was up against a big-block Chevrolet from Roycroft and the winning Pontiac from Semco, among others. The scoring process consisted of average power plus average torque from 3,000-7,000 rpm, divided by cubic inches over an average of three runs.

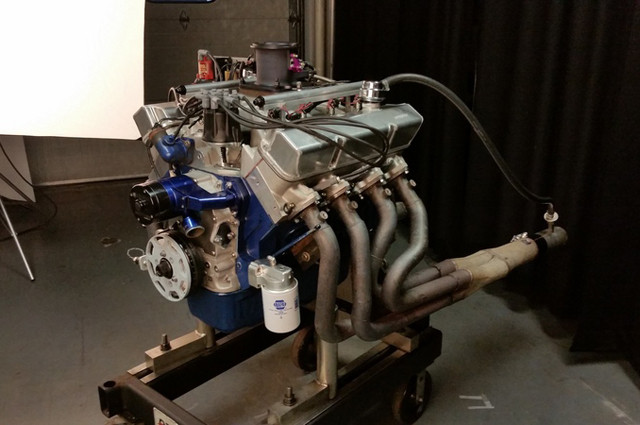

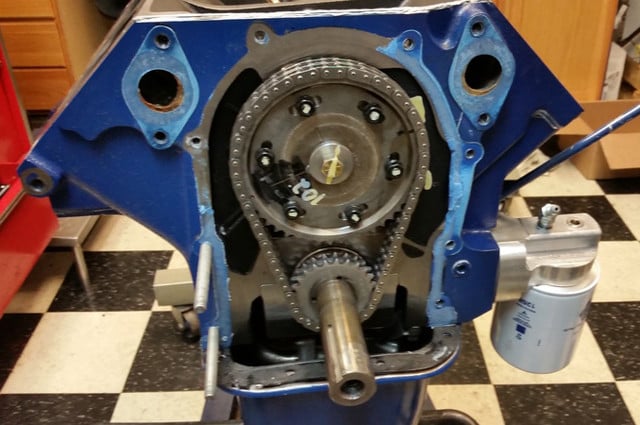

The engine awaiting its torture test at the University of Northwest Ohio for the 2015 edition of the Engine Masters Challenge.

“We used a lot of stuff we had ‘around the shop’. The majority of the build and assembly was handled by William Blair, my machinist at the shop. This is really his engine with my parts selection help. It’s a 427 Ford-based 482ci engine, with a 4.25-inch bore and 4.25-inch stroke,” says Rabotnick.

The engine itself is simple in its beauty. Based around an aftermarket Sideoiler Garage iron casting, it’s filled with a Scat Crankshafts out-of-the-box forging that couples with Scat’s H-beam connecting rods fastened by ARP 2000 bolts.

Survival Motorsports gas-ported the pistons and performed other modifications to the rotating assembly to help boost performance.

Mahle pistons have had the valve pockets reworked, gas ports added, and piston rings that have been severely back-cut to reduce spring tension. The competition had a compression ratio limit of 11.50:1; with these pistons onboard the engine spec’d out at 11.37:1, just under the ultimate limit for the contest.

Lest one think that the cylinder heads are something exotic, Rabotnick says they’re actually the same Survival Motorsports FElony castings the team used in their 2014 EMC effort. They were removed from his personal car and tweaked with a better set of valvesprings to handle the new camshaft profile.

A solid roller camshaft from Comp Cams was installed, with specs of .794-inch/.785-inch lift, 248/252-degrees duration, on a 104-degree lobe separation angle. It was installed at 102 degrees to help boost the torque numbers without hurting performance in the specified RPM range. T&D 1.9:1-ratio shaft-mount rocker arms are on top to actuate the valves.

An Edelbrock Victor 4500 EFI intake manifold ported by Joe Craine and later tweaked by John Marcella of Marcella Manifolds to accommodate the single throttle body sits on top.

“Dyno testing at home went well, with a total of about 54 pulls being made. We tried 49 pulls on EFI getting to the best repeatable timing and fuel curves. I thought I had it pretty well sorted and stuck my old 4500 QFT carb (from the 2005 EMC) on it just to check. In the past I’ve always done this and the EFI always ‘won’, but this time the carb did very well although extremely rich. A quick – and large – jet change brought it even closer, and another jet move brought it right up to the EFI scores, but with a better looking torque curve down low,” explains Rabotnick.

Interesting comparisons between the EFI throttle body and the Quick Fuel 4500-series carburetor, Check out some of the graphs below for more information.

He planned on starting with the carburetor on the dyno, then switch to EFI if they had enough time. As the second engine ‘on the clock’, they had 35 minutes from the first fire up to make as many dyno pulls and changes as they could squeeze into their time window. The best three runs are taken to average the score.

Four pulls were made with the carburetor, and after thrashing to convert everything over, four pulls were made with the EFI system. The results were similar to the data they had recorded at home, with higher peak horsepower numbers and lower torque.

“Between home and contest, we ended up with a best horsepower number of 738 with EFI at home, and a best torque number of 669 with a carb at the show. That 669 calculates to 1.387 pound-feet of torque per cube – inline with my best efforts and in line with expectations on a well-developed engine. The peak horsepower observed at the contest was 728, the peak torque at home was 664. My dyno is within single digits of the one at UNOH,” he says.

Rabotnick was kind enough to prepare a few graphs detailing the engine’s performance. In the interest of simplicity, we’ll let his commentary take over here.

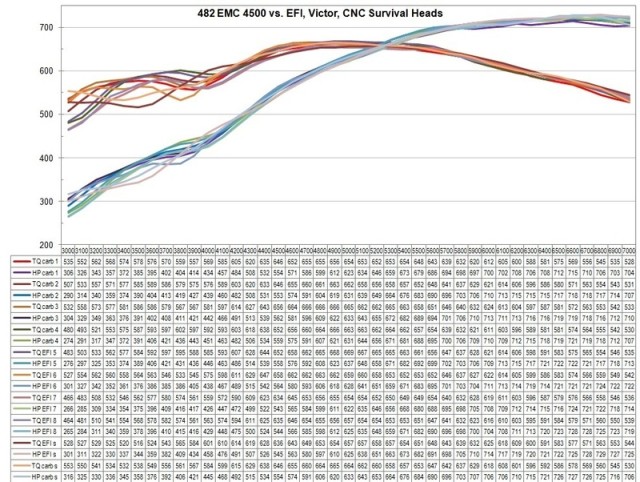

“The first graph is an eye chart showing the eight contest pulls along with a couple of representative home pulls. At EMC we concentrate a lot on the bottom end because that’s where all the variables are. As RPM climbs the graphs show a strong tendency to converge, meaning that power peaks are not as significant a score opportunity as the first 1,000 RPM are. At the contest the dyno operator had a hard time driving the EFI combo and lugged it down to 2,400 rpm a couple times; it’s a challenge to get a good pull started with a huge single blade throttle body and I did not spend enough time refining the fuel curve down that low, but those pulls really killed the bottom end scores as the engine struggled to recover,” he says.

Those with a number are contest pulls, those marked with a “s” are shop pulls at the Survival shop.

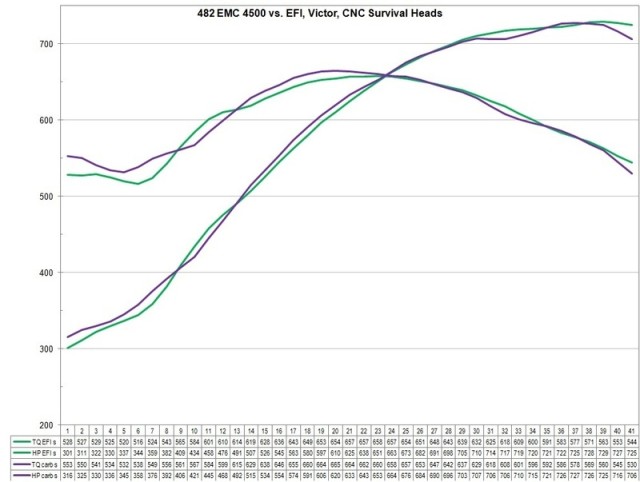

This next graph details some of the pulls they made at the Survival shop, which does a decent job of showing the curve differences between the EFI system and the carburetor.

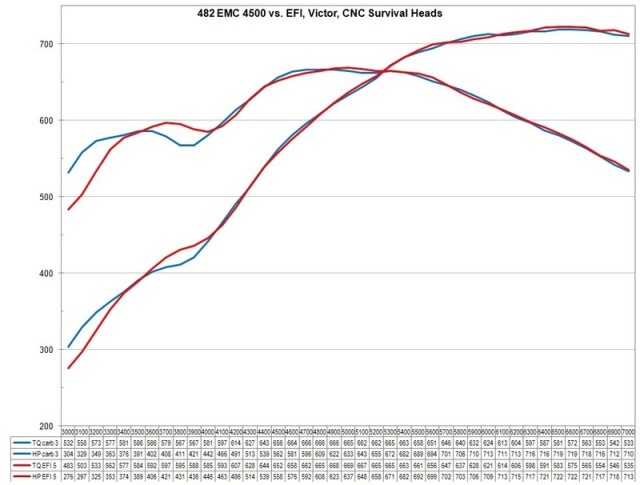

The last chart, shown below, shows the differences between a carburetor pull and an EFI pull at the competition. This shows that the trends are similar between the two, even though the curves are slightly different.

“This engine seemed really reactive to exhaust changes and if you look at the charts it had a significantly different ‘dip’ at the challenge versus the home numbers,” he explains.

The Survival Motorsports shop has an exhaust system that’s very different from the one that was used in the actual competition. Survival’s dyno exhaust has five-inch flex tubing that makes a 90-degree bend just behind the dyno, crosses the room, and exits the building into another 90-degree bend and a set of 5-inch truck mufflers. Conversely, the contest’s exhaust system used 15-foot-long runs of straight pipe venting out of the building and going into the atmosphere.

A two-piece custom timing cover set was tried as proof of concept, and also to allow camshaft adjustment if necessary to change the engine’s powerband.

“The wide powerband really teaches you about the ‘give and take’ of parts selection and tuning. Before EMC, I would never have imagined that you could make over 700hp from an FE with pump gas compression and a cam with under 250 degrees of duration at .050-inch lift. You always come out with more knowledge, and more questions,” sums up Rabotnick.

It’s an interesting look into the limitations and demanding atmosphere of the Engine Masters Challenge from a longtime competitor. Thanks to the Survival Motorsports team for sharing this information with us!