Noted tuner Shane Tecklenburg has his hands in all sorts of interesting projects. Tecklenburg is one of the world’s foremost MoTec engine management system calibrators and is often selected to tune some of the most unique engine combinations out there.

Noted tuner Shane Tecklenburg has his hands in all sorts of interesting projects. Tecklenburg is one of the world’s foremost MoTec engine management system calibrators and is often selected to tune some of the most unique engine combinations out there.

In fact, his work has been featured here on EngineLabs a number of times recently (check those articles out here, here, here, and here).

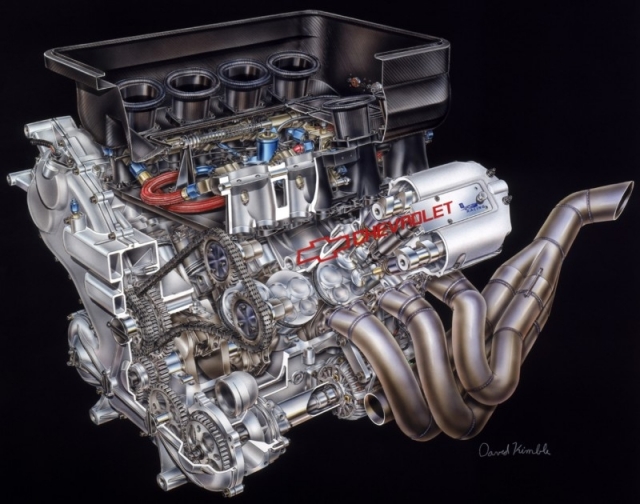

This time around, he’s working with an engine many will never see or hear in person – it’s a naturally-aspirated 3.5L GM Racing Chevrolet V8 Indy engine owned by Mark Nixon and destined for use in Nixon’s 1999 Reynard chassis and destined for vintage-style racing.

This setup carries a unique heritage – the engine was formerly owned by Al Unser Jr. and competed on the Indy circuit in 2002, while the chassis was piloted by Paul Tracy.

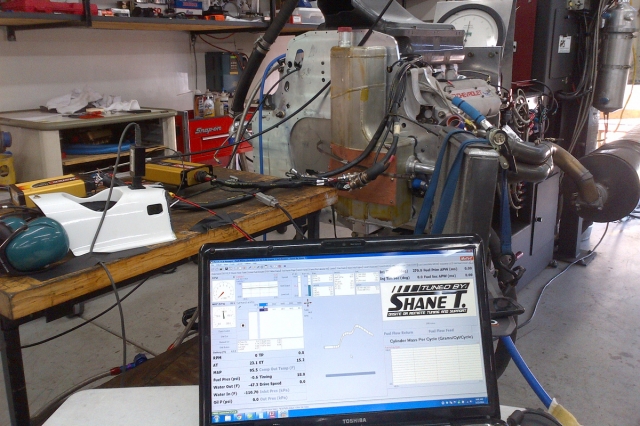

Since Nixon has purchased it, he’s had engine builder George Smidt of Precision Power Racing Engines in Austin, Texas go through the engine and modernize it for his purposes. With Tecklenburg in the house, a MoTec M800 engine management system was selected along with MoTec’s CDI-8 Capacitor Discharge Ignition system to keep the fire lit and provide an immense amount of control over the engine’s operating cycles while inhaling the methanol fuel.

Going for horsepower

Smidt’s successful career as an IndyCar engine builder came about after a number of years building motorcycle race engines from his own shop, and today, he’s back in business for himself – with a pile of Gen I and Gen II Chevy Indy engines that he purchased from Ilmor Engineering at his disposal.

As the engine is tuned to make use of the upper rpm range and has such a small displacement, horsepower is the order of the day, and during their dyno sessions on the DTS Dyno at SRE Engine Techniques in Tucson, AZ, Tecklenburg coaxed 670 horsepower at 9,700 RPM and 350-plus lb./ft. of torque at 9,400 rpm from the bullet.

Chevy's Current IndyCar Engine

To learn more about Chevy’s latest IndyCar engine, check out EngineLabs in-depth review of the 2.2-liter turbocharged V6 by following this link.

“IRL cars only ran on ovals then, so they had a very narrow powerband, from 8,000 to 10,250 rpm. Because of the small displacement, they did not produce a lot of torque. The cylinder heads came from GM already CNC ported and did not require any enhancements. Many of the engine builders deviated from GM and had their own camshafts ground, but the largest horsepower improvement of the Ilmor engine came from their proprietary intake manifold and camshaft package,” says Smidt. “Even with all of these changes, there was probably no more than 20 horsepower difference between the best and worst of the different engine shops. Part of the challenge was to build an engine that made adequate power and was able to run for 500 miles nearly wide open throttle, which is not as easy as it may seem.”

Tecklenburg adds, “Back in 2002 the max rpm limit on an Indy engine was 10,900, and at 10,900 the engines would make around 700 horsepower. But for this application, Mark wanted something reliable that he could play with and not be working on. You’re trying to optimize everything on the engine to get the best average power over the range it will operate in, because that’s where you’re going to get the best acceleration on the racetrack.”

It’s interesting to note how the powerband works on this particular engine – it’s relatively flat around 400 horsepower until the engine comes up on the camshaft, and then it explodes to the tune of over 170 horsepower in a 1,500-rpm stretch from 8,600 to 9,600 rpm.

It’s interesting to note how the powerband works on this particular engine – it’s relatively flat around 400 horsepower until the engine comes up on the camshaft, and then it explodes to the tune of over 170 horsepower in a 1,500-rpm stretch from 8,600 to 9,600 rpm.

Tecklenburg tells EngineLabs that the tuning process is still the same – although the engine is very peaky, it makes a lot of power in its intended operating range and it’s more work to tune the engine because of that tendency to want to be in the band.

“You’re still just trying to match the fuel map with the airflow map. You can’t use manifold pressure mapping to tune with because the engine has individual runners – you have to use a throttle-baed map. Because the engine responds to manifold pressure tuning is much more challenging. The engine doesn’t know anything about throttle angle – that’s just what happens to be what controls the pressure on the back side of the intake valve. So when you can’t measure manifold pressure, you have to infer and guess and use the feeback from the air/fuel ratio compared to your goal to adjust the air/fuel ratio – which is different from a system where you can use a manifold pressure sensor that’s telling you the exact airflow entering the engine,” he explains.

It’s a unique look inside a fine piece of hardware – even though it’s outdated by racing standards, the technology inside is leaps and bounds ahead of most racing engines.