Gasoline and diesel powered engines have been around for over a century. Those years were used to find their niche in the industry — gasoline engines being commonly found in production cars, motorsports and small farm equipment and diesel engines being found in the heavy equipment industry, heavy duty trucks, some commuter cars and even endurance racing as of the early 2000’s.

Many people understand what applications commonly use gasoline and diesel engines, but unless you are well versed in physics and mechanics you may not understand the differences between the two. Jason Fenske of Engineering Explained is a mechanical engineer and a professional at conveying complicated topics in practical terms. This is one of those complicated topics and can easily lead into a long winded rant. So, what better way to cover this topic than with one of Jason’s Engineering Explained YouTube videos?

Many people understand what applications commonly use gasoline and diesel engines, but unless you are well versed in physics and mechanics you may not understand the differences between the two. Jason Fenske of Engineering Explained is a mechanical engineer and a professional at conveying complicated topics in practical terms. This is one of those complicated topics and can easily lead into a long winded rant. So, what better way to cover this topic than with one of Jason’s Engineering Explained YouTube videos?

Jason starts by covering the difference between a spark ignition engine that uses gasoline and a compression ignition engine that uses diesel and the self ignition (autoignition) properties of each fuel. Spark ignition engines attempt to avoid the self ignition process by using a lower compression ratio, high octane fuel and a spark plug to ignite the air/fuel mixture. Diesel engines do not use a spark plug and do not mix the air and fuel on the intake stroke. Instead, diesel engines rely on a higher compression ratio to heat up the compressed air from the intake stroke past the self ignition temperature of diesel and then inject the fuel at the beginning of the power stroke.

The second major difference that is covered is engine speed. A throttle body is used on the intake manifold of a gasoline engine to control engine speed by governing the amount of air being pulled into the manifold in relation to throttle position. Diesel engines do not use a throttle body and instead rely on increasing fuel volume in the combustion chamber in relation to throttle position to control engine speed. Newer diesel engines are starting to use a valve on the intake manifold to control EGR and help with smoother shut downs, but not control engine speed.

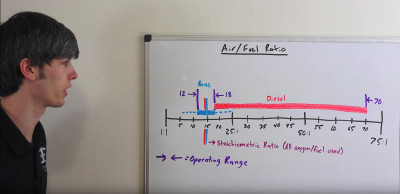

Another major difference is AFR targets. Gasoline and diesel have a very close stoichiometric AFR of about 14.7:1 and 14.5:1 respectively. Gasoline engines use a stoich AFR or slightly leaner at idle and low loads and at higher loads richens up to around 12.5:1 for naturally aspirated engines and 11.5:1 for boosted applications. Diesel engines run much leaner due to its efficiency and engine speed being directly related to fuel volume. A modern diesel engine will idle as lean as 140:1 with no load and as rich as 17:1 at peak torque.

Another major difference is AFR targets. Gasoline and diesel have a very close stoichiometric AFR of about 14.7:1 and 14.5:1 respectively. Gasoline engines use a stoich AFR or slightly leaner at idle and low loads and at higher loads richens up to around 12.5:1 for naturally aspirated engines and 11.5:1 for boosted applications. Diesel engines run much leaner due to its efficiency and engine speed being directly related to fuel volume. A modern diesel engine will idle as lean as 140:1 with no load and as rich as 17:1 at peak torque.

The final difference covered is engine braking. A gasoline engine achieves engine braking by closing the throttle body when off throttle and creating a vacuum in each cylinder, slowing down the engine speed. A diesel engine can achieve engine braking using two different methods depending on the application. Smaller diesel engines use a valve in the exhaust to slow down the engine using back pressure and heavy duty diesel engines use a Jake brake which mechanically opens the exhaust valve at the top of the compression stroke to relieve the compressed air prior to the power stroke.

Gasoline and Diesel engines operate on two completely different engine ignition types and operate at very different efficiency levels. Gasoline engines are much more common due to their lower production cost and cleaner emissions, but burn the fuel less efficiently. Diesel engines make power more easily and burn the fuel more efficiently, but are more difficult to pass emissions with.