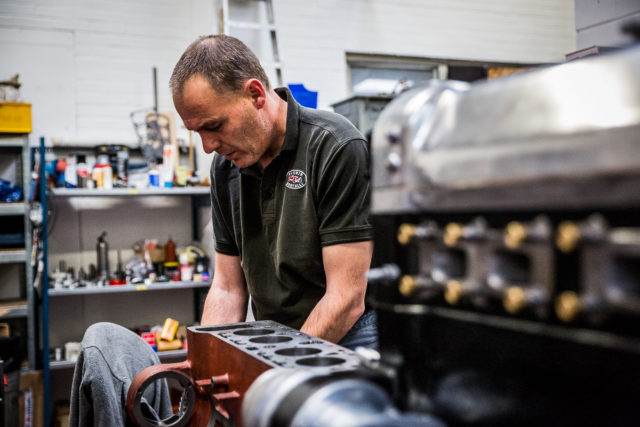

Building vintage engines is not a task for the meek; oftentimes parts are not readily available, and those that are available can be severely out of specification or completely unusable due to corrosion and other factors. So when a video popped up in the ol’ YouTube feed of a 1933 Aston-Martin Le Mans engine on the dyno at Ecurie Bertelli Ltd. [1], we had to investigate further. The challenges to putting together an engine like this can be considered immense, and without the talents of people like Ecurie Bertelli’s Robert Blakemore and his team, would likely be impossible.

This particular engine is a 1933 Aston-Martin Le Mans build which features 1,495 cc of displacement. This is achieved through the use of a 69 mm bore and exceptionally-long 99 mm stroke, which Blakemore tells us was used for tax efficiency, of all things. The single-overhead-cam, two-valve-per-cylinder engine uses a dry sump oiling system and a pair of horizontal SU carburetors for fuel introduction into the engine.

Not only does Bertelli rebuild the engines, they are the world’s leading restoration facility for these amazing pieces of automotive history. The complications which occur during the process of restoring vehicles like this are especially arduous when it comes to Aston-Martin vehicles as the company was not one of the prominent automobile manufacturers of the time.

“There were only 681 Aston-Martins made before World War II, there are no old parts worth re-using left. We do try and source old parts for things that are visible or make new parts look old,” says Blakemore.

Engine components prove especially difficult to source, so to combat this issue, the Bertelli facility is able to rely on information they’ve acquired and produce replacement parts for use in the vehicles.

“The challenges are blending improvements with keeping the cars original. We don’t keep replicating the poor design of the past, but only upgrade the small details. We make all the spare parts here from approximately 1,200 original works drawings and the engine in the clip is made from 100-percent new parts that we manufactured,” says Blakemore.

Although one might think there would be large improvements to be gained through the use of modern machining equipment, that’s not necessarily the case. The Aston-Martin manufacturing methods of the day were stringent, although not necessarily efficient.

“The machining in period was very good indeed. Aston-Martin made extremely high quality products and even before the war would dyno each engine, dismantle it to check it before re-assembling, testing and fitting to the cars–no wonder they made no money!” says Blakemore.

The gains they’ve realized have come through the use of more robust, modern materials, along with revised designs that have been developed to take advantage of current manufacturing methods. These new parts allow them to spin the engines higher and harder than they were during their heyday.

“We have improved the power through making the bottom end strong enough so we can rev these engines to 7,000 rpm for a race engine compared to 5,250 in period. We also manage the gas flow better with improved exhaust and inlet manifolds as well as better gas flowed cylinder heads,” Blakemore explains.

The long exhaust primaries used in this configuration are not chosen for their power-making capabilities; rather, they were selected to help fit the exhaust into the chassis, but Blakemore says they do work quite well due to the long crankshaft stroke used in the engine.

There aren’t any specific break-in processes that are followed once the engine is fitted into the chassis; these are all done on the engine dyno. Step testing, high-RPM testing, and the like are all completed during the session as seen here. This way the rings are fully seated and the carburetion is optimized to provide flawless performance.

With such limited displacement, the engine does not produce massive power–just 82 bhp and 87 lb-ft of torque–although Blakemore says that an engine in full race trim will crank out 110 bhp. With this powerplant the Le Mans was capable of approximately 85 mph top speeds and 0-50 times of 16 seconds. In that era, the Le Mans was one of the quicker vehicles. Enjoy the clip!