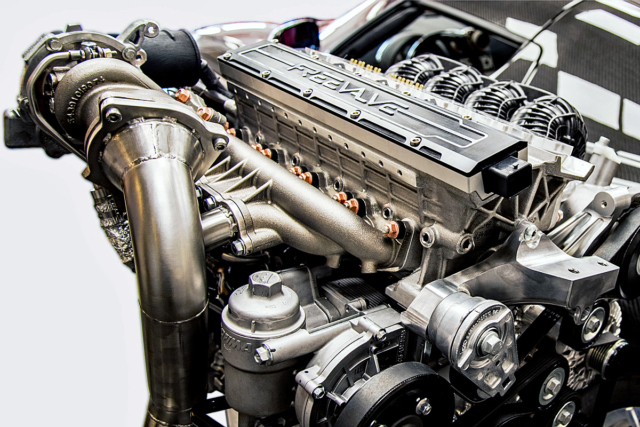

At the Beijing Motor Show in April of 2016, Koenigsegg Automotive [1]‘s sister company, FreeValve [2], announced its partnership with Shanghai based Qoros Auto [3] to develop the first mass production consumer cars featuring camless FreeValve pneumatic-hydraulic-electric-actuator (PHEA) valvetrain technology. A little over six months later at the Guangzhou Motor Show, FreeValve and Qoros revealed an operational model of this system using a modified version of the existing German/Austrian designed 1.6-liter turbocharged engine called “Qamfree” that is already preparing for fleet testing.

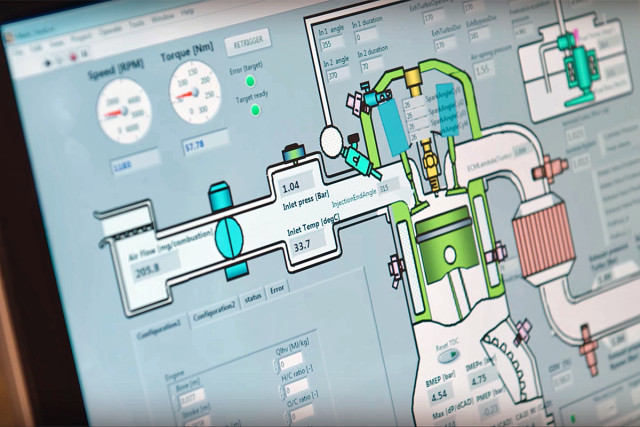

In the video above by /Drive [4], Christian von Koenigsegg, Chairman of the Board for FreeValve and founder/CEO of Koenigsegg Automotive, gives us a thorough walkthrough of the latest generation of this technology that will be sure to keep the internal combustion engine in mass production for at least the next few decades. [5]

[5]

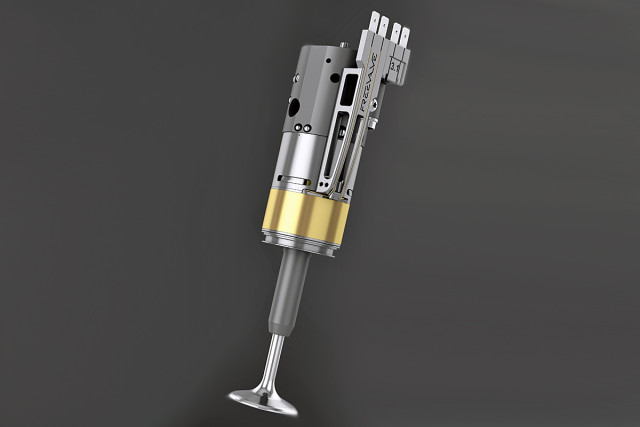

Using independent control of the lift and duration of each individual intake and exhaust valve, the main goal behind the pursuit of this technology is to reduce emissions and increase fuel efficiency; with a secondary emphasis on performance.

Each PHEA controlled intake and exhaust valve has an independent port coming out of the combustion chamber. On the exhaust side, only half of the ports are fed through the turbine housing of the turbocharger, while the other half flow straight into the exhaust system. This allowed the engineers to decrease exhaust backpressure and ditch the wastegate entirely in favor of valve timing based boost control.

From an emissions standpoint, the independent valve control allows for cold start combustion events that will push flames out of the combustion chamber and into the exhaust system to heat up the catalytic converter much faster than even a conventional naturally aspirated engine (which is when the majority of tailpipe emissions occur). [7]

[7]

By using FreeValve, the throttle body was also eliminated in exchange for throttle control integrated directly at the valve; providing improved throttle response, weight savings, and increased fuel efficiency by removing the need to draw a vacuum between the the throttle body and valves. [8]

[8]

With no other changes to engine other than the addition of the “Qamfree” head design, the 1.6-liter turbocharged engine increased power by about 45 percent, from 160 horsepower to 240 horsepower; and increased torque by about 47 percent, from 177 lb-ft to 236 lb-ft of torque. This system also reduces fuel consumption by 15 percent and emits 35 percent fewer tailpipe emissions when compared to a traditional camshaft engine of the same platform.

[9]

[9]Christian von Koenigsegg and his wife at the “Qamfree” reveal at Guangzhou Motor Show in November of 2016.

The benefits go beyond just the increase in power and fuel efficiency. Manufacturers that implement FreeValve style technology in the future are able to cut costs by eliminating expensive components like the throttle body, camshafts, cam drive system, timing gear and cover, wastegate, pre-catalytic converters and direct injection systems. Which also cuts the weight of the engine by about 40 pounds, and makes the packaging much more compact taking off almost 2-inches in height and 2,75-inches in depth, giving manufacturers more packaging options.