Electric vehicles may be old hat on America’s roads, but America’s skies are a different story. Manned electric aircraft have been around since the early ’70s, but electric flight’s nagging power-to-weight problem–in short, underpowered batteries attempting to drive heavy electric motors–have kept electric aircraft light and mostly experimental. Advances have been made–an electric version of the Cessna 172 (with a takeoff weight of roughly 2,450 pounds) has flown–but anything that could be considered even remotely commercially viable has remained elusive. But engineers at the German industrial giant Siemens may have finally taken a big step in the right direction with what appears to be a viable electric aircraft engine.

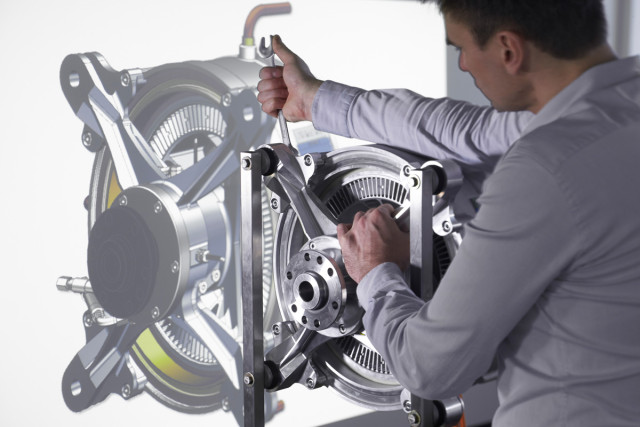

Using filigreed aluminum and, later, carbon-fiber to slash the weight of the engine’s end shield–the component on which the bearing and propeller ride–by up to 75 percent, Siemens was able to produce a 50-kilogram (approximately 110-pound) motor that can deliver a continuous output of 260 kilowatts (roughly 350 hp) an impressive weight-to-performance ratio of about five kilowatts per kilogram. Many industrial applications, on the other hand, operate with a less than 1-to-1 weight-to-performance ratio, while the drive systems in electric vehicles are commonly in the 2-to-1 range. Additionally, because the motor spins at only 2,500 rpm, it can deliver power to the propeller directly, eliminating the need for the added weight of a transmission.

Using filigreed aluminum and, later, carbon-fiber to slash the weight of the engine’s end shield–the component on which the bearing and propeller ride–by up to 75 percent, Siemens was able to produce a 50-kilogram (approximately 110-pound) motor that can deliver a continuous output of 260 kilowatts (roughly 350 hp) an impressive weight-to-performance ratio of about five kilowatts per kilogram. Many industrial applications, on the other hand, operate with a less than 1-to-1 weight-to-performance ratio, while the drive systems in electric vehicles are commonly in the 2-to-1 range. Additionally, because the motor spins at only 2,500 rpm, it can deliver power to the propeller directly, eliminating the need for the added weight of a transmission.

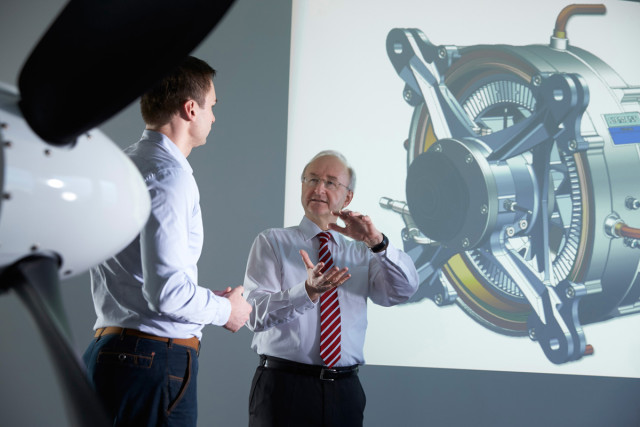

Siemens says that the new engine should be able to power aircraft with takeoff weights up to two tons. That’s still not close to the payloads seen in commercial aviation (a Beechcraft Bonanza G36, for example, comes in at slightly under two tons), but Frank Anton, head of the company’s eAircraft research unit, says that commercial applications are just a matter of time. “This [motor] will make it possible to build hybrid-electric aircraft with four or more seats,” he explains, “and we’re convinced that the use of hybrid-electric drives in regional airliners with 50 to 100 passengers is a real medium-term possibility.”

Once the power hurdles are overcome, electric and hybrid-electric aircraft will provide the airline industry and the general public with a wide variety of benefits. Fuel consumption could be cut by roughly 25 percent, while people living near airports would enjoy a healthy drop in both noise pollution and CO2 emissions into the atmosphere.