Longtime bracket racer Paul Winkelbauer races a street-legal 1988 Ford Ranger in the local bracket events at his home track of Heartland Park in Topeka, Kansas, and a winter engine build from Siebert Performance had him chomping at the bit to get back on the track. He managed to get the project finished up in time to earn a divisional grade point at Great Bend, then took the track for the Kansas Nationals in Super Street.

His motivation?

“I just wanted to race a national event at Heartland Park,” he says. “I’ve been bracket racing for about eight years, but I didn’t think I would do very well throttle-stop racing.”

Stout .00x reaction times in every elimination round changed his mind, as he ran through the field, including Timothy Fletcher, Larry Zieber, Bob Hallgren, and Robbie Mayse. He met Greg Parson in the final round, where Winkelbauer left the starting line with an outstanding .006 reaction time to help him take the holeshot win, 10.916 to Parson’s 10.909.

The engine combination in the Ranger was built by School of Automotive Machinists‘ graduate Luke Siebert and his team at Siebert Performance. The company specializes in engines for all racing disciplines, carburetor tuning for performance applications, along with parts sales and consultation.

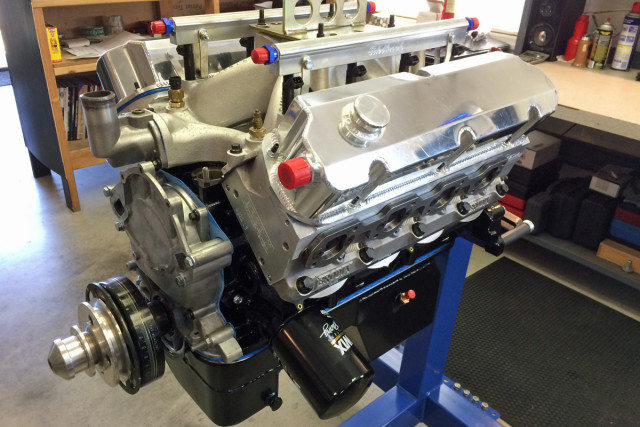

The small-block Ford engine–designed for ultimate predictability with regards to its performance–is based around a Dart 8.200-inch deck-height Iron Eagle block with 4.125-inch bores, a 3.400-inch-stroke Eagle forged-steel crankshaft and 5.400-inch H-beam connecting rods that are topped with forged CP pistons. The track-friendly, torque-heavy engine displaces 363 cubic inches.

“When building an engine for bracket racing, there are three main goals in mind–longevity, predictability, and power. Although we are after maximum power, we must do so knowing that customers want to run their engine two and three seasons between freshen-ups. Depending on the success of the racer and part of the country they live in, that can range between 150 and 400 runs between normal rebuilds. So 1.000-inch lift camshafts, super fine cylinder wall finishes, and 9000+ rpms are not suggested,” says Siebert.

Providing that balance between performance and longevity is a battle he faces on every engine build, especially with regards to bracket racing engines.

“Cubic inches, compression, cylinder heads, camshaft, all of the familiar faces are still important, with longevity in mind. Also, running the engine in its most efficient rpm range. A tight converter will make an engine hate poor weather conditions. Naturally aspirated or supercharged is the way to go because of consistency in performance. Although, nitrous is used from time to time to enhance finish line driving,” he says.

This particular engine has been topped off with a set of M2 Systems’ finest CNC-ported Brodix Track 1 cylinder heads and Jesel valvetrain components, and has been as quick as 10.03 in the quarter mile with Winkelbauer behind the wheel of the Ranger. Relatively unusual among bracket racers is Winkelbauer’s choice of F.A.S.T.‘s XFI fuel injection; however, this also fits in with the predictability theme.

Alternate views of the engine.

“Coolant and engine temperature play into how we setup ring gaps. If it were a Comp Eliminator engine that we could run the engine chiller on and tow to the lanes, we could get away with tighter gaps. Our customers race in anything from 35 degree weather to 105 degree weather, and expect to be able to splash fuel in the tank and go up to run the next class. Super tight ring gaps will simply not work in these conditions. Good piston design, ring design, and cylinder honing can still yield awesome ring seal and good crankcase vacuum with evac, vacuum pump, or dry sump systems,” Siebert explains.

One thing that Siebert believes strongly in, especially for drag-race engines, is testing, testing, and more testing to determine the engine’s capabilities.

“Dyno testing and data acquisition are key in making any car run to its full potential and be predictable. If you take the time to dyno test your engine and get the fuel side right with oxygen sensors, and you find where it likes the timing, your engine will dial better,” Siebert says.

“Consistency is good, predictability is better,” he sums up.