The Pontiac crowd stands a few steps away from the mainstream big three, and that endears their proprietary performance to enthusiasts who just don’t identify with the brand-wars. With the same goals universal to all engine builders, unique solutions become the most interesting. We all have the problem of never enough horsepower so where do we go from there? Efficiency per cubic inch is the name of the game, and with so many builders going forced induction in the name of power per cubic inch it’s refreshing to see a build that takes good ‘ole displacement and gets the very best out of it.

The Pontiac crowd stands a few steps away from the mainstream big three, and that endears their proprietary performance to enthusiasts who just don’t identify with the brand-wars. With the same goals universal to all engine builders, unique solutions become the most interesting. We all have the problem of never enough horsepower so where do we go from there? Efficiency per cubic inch is the name of the game, and with so many builders going forced induction in the name of power per cubic inch it’s refreshing to see a build that takes good ‘ole displacement and gets the very best out of it.

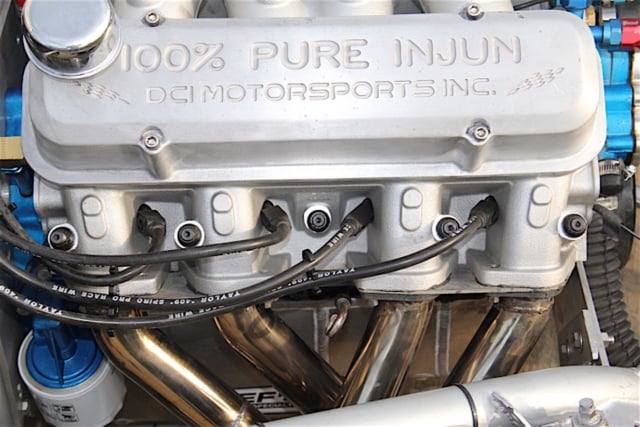

Don Johnston of DCI Automotive is a pioneering builder on the Pontiac scene, but builds engines of all flavors, shapes and sizes. His recent endeavor was to develop a powerplant for the street crowd that put down big power on pump gas. The foundation for this build would be a GM factory 455 block from 1973, topped with Johnston’s own design heads.

“It’s my cylinder head design but it’s a copy of the Pontiac Ram Air 5. Pontiac back in the day had a program that was similar to the Ford 427 Tunnel-Port, and what had happened was the engineers knew each other — the Ford engineer just happened to be at the track one day with the new tunnel-port head and the engineer from Pontiac said ‘hey I’d like to take that thing home for the weekend and give it back to you Monday.’ My head is a copy of that on steroids, as cast it flows a little over 400 CFM, and with a little porting it will go over 500 CFM,” explained Johnston. “The entry level valve sizes are 2-1/4, and 1.68, and the length is long because we raise the intake port 1-1/2-inches. It has a new combustion chamber design and we redesigned the intake and exhaust ports considerably. The pushrod goes right down through the center of the port like in a Ford tunnel-ram.”

This package had a goal of 800 horsepower slated, and Johnston thought his head design would be good for it but would need the backing of a 535-inch displacement. To his surprise a 455 provided the necessary volume, even on the mild specs to which it was built. The contents for this naturally-aspirated Pontiac are nothing glamorous — making up the bottom end are an Ohio crank forged for 3.25-inch mains, Eagle H beam 6.80-inch rods, an LSM Engineering cam, and COMP lifters.

“Right now the engine currently is all off-the-shelf parts, nothing trick here. It uses an off-the-shelf Probe piston with a standard ring, stock bore, stock stroke, 455 factory block. It has a hydraulic profile roller cam in it, we are running solid roller lifters on it but it’s a hydraulic profile. The camshaft is a street profile, I designed it for the Engine Masters challenge and they wouldn’t allow me to run this head in the Challenge, it’s only got 37-degrees of overlap in it and the one we’re going to put in it has 63. It’s actually a 10.23:1 compression and it will run on 91 octane. The max-rpm we’ve seen out of the engine is 7,000 and the torque curve is super flat, it’s making 600 lb-ft from the time we start the pull to the end,” illustrated Johnston.

“Right now the engine currently is all off-the-shelf parts, nothing trick here. It uses an off-the-shelf Probe piston with a standard ring, stock bore, stock stroke, 455 factory block. It has a hydraulic profile roller cam in it, we are running solid roller lifters on it but it’s a hydraulic profile. The camshaft is a street profile, I designed it for the Engine Masters challenge and they wouldn’t allow me to run this head in the Challenge, it’s only got 37-degrees of overlap in it and the one we’re going to put in it has 63. It’s actually a 10.23:1 compression and it will run on 91 octane. The max-rpm we’ve seen out of the engine is 7,000 and the torque curve is super flat, it’s making 600 lb-ft from the time we start the pull to the end,” illustrated Johnston.

Along with Johnston’s own designed heads comprising the top-end, is his cast aluminum intake manifold. This plenum design was inspired by a desire to keep under-hood packaging neat and provide the ability to run an assortment of different induction options.

Along with Johnston’s own designed heads comprising the top-end, is his cast aluminum intake manifold. This plenum design was inspired by a desire to keep under-hood packaging neat and provide the ability to run an assortment of different induction options.

“Right now it has my factory cast intake manifold on it, which is very unique. When I made these heads I was targeting a street audience, and everybody wanted an intake that would fit under the hood. I wrestled with that because I didn’t want to design an intake that would limit my head — so what I did was make this thing like a big bathtub. We can use either three two-barrels, two fours, a single four, a blower, or whatever you want. I was trying to accommodate a wide range of adaptability and thats what I came up with,” Johnston continued.

The versatility of Johnston’s cast manifold has allowed him to test the 455 with a number of carburetor options. The final and current iteration has been the result of a string of testing. “Currently we’ve dynod with and 850 cfm 4150 carb, and it made 739 horsepower, then we put a Dominator on it and it made 750 hp, then we put a two-inch plenum riser on the intake to make the plenum area bigger and it’s at 770 hp now, I think it’s going to make 800.”

Future plans for the induction system are already underway, Johnston has CAD-designed a new sheetmetal fabricated intake manifold and is awaiting the final machining of the parts. Combined with a new cam grind with a more aggressive amount of overlap and some ignition timing improvement he expects to further improve this potent package. “The volumetric efficiency right now is about 108 percent and that’s going to go up I’m sure. I’m thinking we have an LS-eater here but definitely different!” he boasted. “We’re not done — right now the engine has made 780 hp but we can’t get it to repeat because the timing is bouncing around too much. The next step is to put a crank-trigger on it, right now we can repeat at 770.”

Future plans for the induction system are already underway, Johnston has CAD-designed a new sheetmetal fabricated intake manifold and is awaiting the final machining of the parts. Combined with a new cam grind with a more aggressive amount of overlap and some ignition timing improvement he expects to further improve this potent package. “The volumetric efficiency right now is about 108 percent and that’s going to go up I’m sure. I’m thinking we have an LS-eater here but definitely different!” he boasted. “We’re not done — right now the engine has made 780 hp but we can’t get it to repeat because the timing is bouncing around too much. The next step is to put a crank-trigger on it, right now we can repeat at 770.”

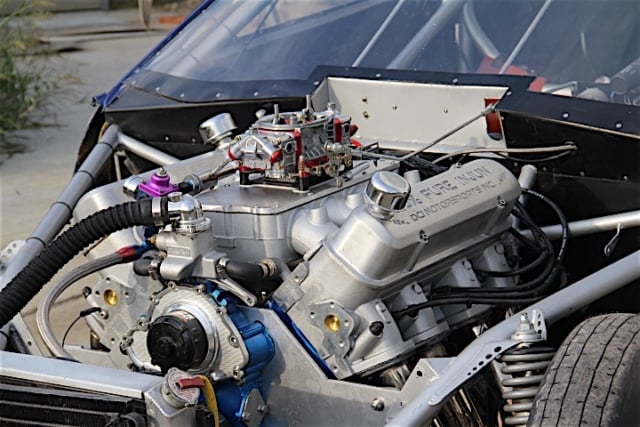

While this engine has been mainly used as a test bed to develop this package, don’t think for a minute that Johnston isn’t going to put it to work. “It is going to go in a car, I do have a tube-chassis drag car, we going to get it out a couple of times before the Pontiac Nationals at Norwalk this year, and then of course race it there. My car weighs 2550 with a driver in it, so we’re thinking we going to run low-8s around 165 mph, we’re going to try to qualify for Quick-16 that weekend,” Johnston concluded.

We look forward to the tuning developments with this volumetrically efficient and interesting package. Look for the mean Pontiac out at the track!