While the supercharger vs. turbocharger debate will never be resolved, engine builders can agree that switching from one boost option to the other is certainly not without serious challenges. There are packaging issues, endless tuning refinements and even weight adjustments that must be addressed.

Witness the transformation of a Pro Mod car campaigned last year by Don Carter with a screw blower atop a 526ci Bob Miner all-billet longblock. Scott and Terry Rakestraw of Turbos Direct purchased the car over the winter—minus the blower and fuel system—and, of course, wanted a pair of the company’s finest Garrett turbos on the car. They recruited Bothwell Motorsports to handle the conversion and campaign the car with Rick Snavely in the driver’s seat.

“Bob said no one he knew had put turbos on one of his combinations,” remembers Steve Bothwell, who handles the tuning chores on the car. “So, it’s the first of its kind.”

The first time out at a sanctioned race, the team struggled so much that they chalked up the experience as a test session. Next time out at the NMCA West at Fontana in late June, Snavely posted the quickest qualifying time and dominated his opponents in the next two rounds to win the Garrett Pro Mod class.

“And this car is not even close to being happy,” Mike Merrell, shop manager at Turbos Direct, tells EngineLabs.

“We’re making the power,” adds Bothwell. “It’s just harnessing the power.”

The basic longblock features a Miner billet block and heads combination, which is an evolution of the old Arias-Fontana legacy. Nick Arias Jr. originally designed the cylinder head as hemi option for Chevy big-blocks, and then developed an aluminum cylinder block with improved features like a raised cam location. That setup became popular in drag boats and truck pulling as well as on the drag strip. When Miner acquired the rights from Fontana, he developed billet versions that, again, are well-known in truck-pulling circles and on the Pro Mod circuit.

With Rick Snavely at the wheel, the Turbos Direct Camaro won the recent NMCA West Pro Mod division. Here Snavely defeats the ’57 Chevy of John Scialpi with a time of 5.342 seconds in the 1,000-foot race.

Looking for a baseline

The Camaro-bodied car was built by Jerry Bickel and raced for only a few months, running as quick as 5.72 in the quarter mile.

“We were just trying to understand the package when we got the car,” remembers Bothwell. “We didn’t have a base to go off.”

Bothwell left the compression ratio at 12.5:1 but changed cam timing in anticipation of adding the two turbos.

“We pushed it up, advanced the cam to help the turbos spool up on the bottom end,” adds Bothwell, noting all development work has been done at the track.”

The turbos are mounted at 37 degrees, which prompted some concern over lubrication issues but has proven successful, so far.

“You sometimes wish you could do it different and put the engine on the dyno first,” says Bothwell.

The rotating assembly of a Bryant crank, GRP connecting rod and Arias pistons were left untouched, but Bothwell did convert to dry sump oiling.

TurboSmart supplied the wastegates and blow-off valves.

“We believe in dry sump, so we moved to a Barnes 5-stage pump and Peterson tank,” says Bothwell, noting that two stages are used to scavenge from the oil pan and two stages scavenge from the turbos. “We also put spring oilers in the valve covers. We rev these engines. This motor’s seen 10,200, and when you’re on the rev limiter it’s hard on the valvetrain. We’ve had the pan off twice, looking up with the bearings down. Haven’t seen anything.”

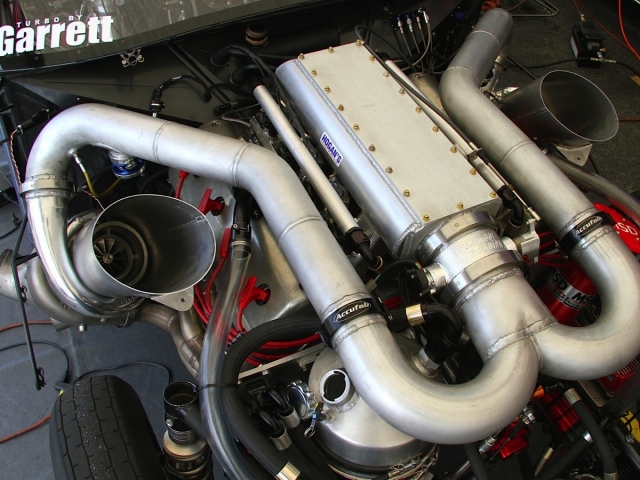

The twin Garrett GTX5518 turbos were modified at Turbos Direct with billet backplates and a lightened center bearing housing. These turbos feature an 88mm inducer with Garrett’s new GTX 11-blade compressor wheel and a standard 55mm turbine wheel in a 1.15 A/R housing on the exhaust side. The units are fully SFI-certified for NHRA competition.

“Depending on the unit, we can pull nine to 11 pounds per turbo,” says Merrell. “Ten pounds to a drag car is a ton. Other than that, they’re off-the-shelf Garrett. There’s no other reason to mess with them.“

Locating the turbos was the biggest challenge for the team, and Bothwell took a big chance.

“Because of the turbine housing and the cross-bolt section on the back, we had to mount at a pretty wicked angle,” says Merrell. “They’re at 37 degrees, but for packaging choices we didn’t have a choice.”

Fuel delivery is with a Waterman pump and Big Stuff 3 EFI system. Note the dry-sump conversion using a Barnes pump and Peterson tank. Noate the spring oilers. Spark is via a MSD magneto.

“People would say you can’t do that,” echoes Bothwell, “because we’re not distributing the oil evenly. You’re putting it all on the back of the bearing.”

The position helps reduce bends in the airflow ducting to the manifold while keeping the weight low for a better center of gravity. It also allows direct air inlet from huge 7-inch fresh-air ducts on the hood instead of below the car where track debris could enter the system.

“We don’t want to kill a turbo because we’re getting rocks in it,” says Bothwell.

“Fast Eddie” fabricated the 2.5-to-2.25 headers, and TurboSmart provided the 60mm wastegates and 50mm blowoff valves that are instructed by a Hyperaktive boost controller, which is spec for NHRA competition.

Getting the boost up

A Hogan intake manifold supports a Wilson 105mm throttle body and a pair of Big Stuff 3 injectors—which are fed methanol by a Waterman 21 gpm pump— for each port. A MSD magneto provides spark.

“The most boost we’ve thrown at it is 38 pounds right now,” says Bothwell.

After a single run in the first round at Fontana, Snavely clicked off 5.342 and 5.320 runs (1,000-foot distance) to win the trophy. The team’s goal is to run NHRA next year, so intercoolers were not installed, although they are legal for the NMCA competition.

“We believe in intercoolers but we also want to run NHRA. For me, as a tuner and trying to get the car figured out, I didn’t want to go from an intercooler to no intercooler,” says Bothwell. “We need to race it one way. Hopefully, this is a turning point this weekend.”