If you’ve been into engine building long enough you’re probably heard of Plastigage — though rarely seen these days, this mechanics’ helper is geared toward the garage builder rather than the professional shop. The investment required to own your own set of precision measuring equipment for engine building can be costly, and may be a barrier to entry for the grassroots level enthusiast.

[1]The cheap and consumable option is Plastigage. If you have an engine with some mileage on it you may be contemplating a rebuild, of course this entails things like pistons, rings, cylinder honing, cylinder head work etc. but more important than all of those are the bearing and journal surfaces that keep your engine spinning true and well-lubricated.

[1]The cheap and consumable option is Plastigage. If you have an engine with some mileage on it you may be contemplating a rebuild, of course this entails things like pistons, rings, cylinder honing, cylinder head work etc. but more important than all of those are the bearing and journal surfaces that keep your engine spinning true and well-lubricated.

If you are dropping off your basket case motor at a machine shop or builder they will likely do all the diagnostic and measuring leg work for you — but there are those of us in the hobby who do for ourselves and like to have a hand in each step of the process. In which case the best compromise is to send out parts like heads, connecting rods, and crankshaft for a journal polish or valve job.

In the mean time you are no doubt plotting your plan of attack upon the successful reconditioning of your engine parts. Buying new bearings is one of the fundamental first decisions you have to make. As your journals wear and are polished material is lost — resulting in looser tolerances and potentially low oil pressure. To accommodate this wear smaller inside diameter bearings must take the place of the originals. But how do you know how much wear has taken place? What are your current clearances.

This is where Plastigage comes into play. Rather than using a dial indicator, micrometer, or calipers to measure the the crank journal diameters, and then comparing them with the bearing inside diameters, all you need is you third arm appendage during an engine build — a torque wrench.

In the video Eric The Car Guy illustrates the simplicity of this consumable measuring tool. As he points out, even if you own all your own measuring equipment Plastigage is a great way to double check your clearances are correct before final assembly. Demonstrating the process, Eric accesses the bottom end of the engine via the removed oil pan and removes a rod cap.

After cleaning the oil from the bearing surfaces to make for an accurate measurement Eric breaks off a journal-width piece of the green plastic filament and places it across the journal. Reinstalling the bearing and cap he proceeds to torque the rod bolts to the specified amount. This action smashes the Plastigage filament, spreading it out.

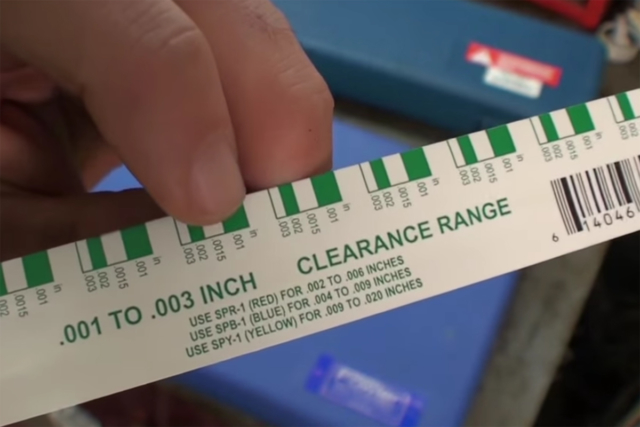

[4]Removing the freshly torqued cap exposes the Plastigage and clearance measurements can be deduced. Using the paper ruler supplied with the Plastigage, the width of the smashed filament is compared to the best-fit white or green block on the ruler. With the referenced bearing clearance you can then decide how much has worn away, and if your new bearings are within tolerance.

[4]Removing the freshly torqued cap exposes the Plastigage and clearance measurements can be deduced. Using the paper ruler supplied with the Plastigage, the width of the smashed filament is compared to the best-fit white or green block on the ruler. With the referenced bearing clearance you can then decide how much has worn away, and if your new bearings are within tolerance.

Plastigage may seem a crude solution to a fine problem but it is a tried and true method of double checking your work, while it’s advisable to employ other measuring tools as well, it can sure save you a few dollars.