The current rumors and dialogue surrounding new rules for NHRA Pro Stock has certainly increased the interest level from within the class, especially among engine builders; but whether these swirling winds of change would actually generate renewed enthusiasm from fans in the stands and boost participation from racers and sponsors remains an uncertainty.

The current rumors and dialogue surrounding new rules for NHRA Pro Stock has certainly increased the interest level from within the class, especially among engine builders; but whether these swirling winds of change would actually generate renewed enthusiasm from fans in the stands and boost participation from racers and sponsors remains an uncertainty.

If NHRA doesn’t announce a new rules package by Indy, then I highly doubt anything will happen for next year.–EngineLabs source

Here’s what EngineLabs knows.

A well-placed source says newly appointed NHRA president Peter Clifford set forth only two specific directives at a power meeting between sanctioning body officials and Pro Stock teams. Slightly paraphrasing, according our source, Clifford said, “I want the hood scoop gone, and I want fuel injection.”

All other ideas, suggestions and rumors apparently have been spawned from side talk among the players, wish lists from well-meaning observers and “here’s what I heard” posts on forums or social media. Of all the additional topics that have been proposed, EL believes that only instituting rev limits and adjusting the length of the wheelie bars have any real possibility of definitive action on the part of the NHRA in addition to addressing EFI and hood-scoop proposals.

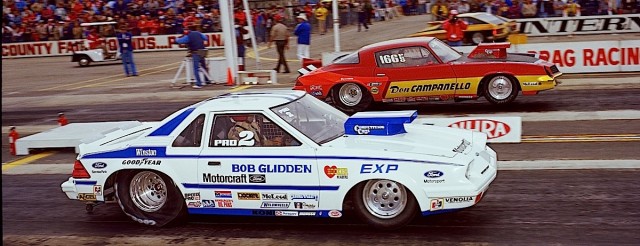

Remember the glory days of Pro Stock when the racecars looked like real cars and Ford vs. Chevy meant war in the stands? Hopefully the current rules discussion will help point Pro Stock in that direction again. NHRA photo

Get the fans closer to the teams

EL has also been told that another meeting between teams and officials will be held this weekend at the Mopar Mile High Nationals in Denver, Colorado. Most likely, teams will also meet with their sponsors and factory reps to discuss the possibilities before the rules gathering.

“If NHRA doesn’t announce a new rules package by Indy (US Nationals scheduled over Labor Day weekend) then I highly doubt anything will happen for next year,” says our source, noting that after Indy there wouldn’t be enough time for teams and suppliers to implement the changes effectively.

NHRA may mandate, or at least request, that Pro Stock teams come out from the shadows of their pits and face the fans--possibly as early as the next race in Denver. Teams have been criticized for too much secrecy and coverup, much to the disappointment of the fans.

Also a possibility for the Denver race is a request or command to all Pro Stock teams to come out of their cocoons. One of the strongest and most valid criticisms of today’s teams is the practice of hiding their cars in the deepest trenches of their pits with full body and hood wraps. The secrecy is intended to keep spying eyes from the competition at bay, but it also keeps the fans from becoming more intimate with the cars and teams. According our source, NHRA will either ask or demand (he’s not sure which) that the Pro Stock teams turn their cars around and bring them to the forefront of their pits without any protective covers. Most of the cars have carbon-fiber shields around the intake runners, so the critical elements of the manifold design should remain covert.

Even though the Pro Stock community has its marching orders and a destination (whether or not it’s a final destination will bear out in the near future), it has no idea of what path to take on this journey. The devil is always in the details, and two initiatives seemingly as simple eliminating the hood scoop and implementing EFI (we assume Clifford was speaking of electronic fuel injection and not mechanical fuel injection) will generate a long bullet list of questions and options that will have to be addressed.

A Top Fuel or Funny Car engine is an open book for fans in the pits, but you can't even watch a Pro Stock team check valve-spring pressure.

For example, slicing off the iconic hood scoop will improve driver visibility and perhaps boost top-end speed due to less drag, but it will also require revised thinking of how to get air to the engine. If the rule makers opt for cowl induction, then the Camaro has a leg up on the competition since a traditional GM-style cowl hood is already approved on the Camaro body. Cowl induction also leads to questions about inlet opening area, distance from the windshield and other factors. The other option is allowing air in through openings on the front fascia, similar to what Pro Stock Truck utilized when it ran from 1998 through the 2002 season. Again, the size and placement of those openings must be addressed.

The Camaro body already sports a cowl-induction hood, but the Mopars would have to have a new hood design if cowl-induction is the new method of getting air to the engine. NHRA photos

Rulemakers also have the option bringing in fresh air through the front fascia, similar to Pro Stock Truck designs.

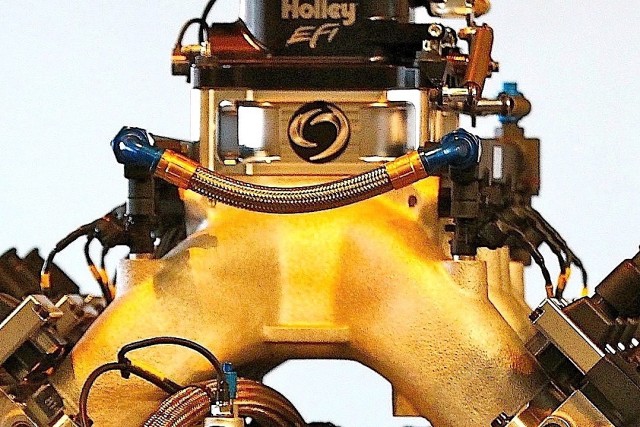

Notice how high the injectors are positioned in the intake runners? NASCAR determined that placing the injectors closer to the intake valves would give certain cylinder heads an advantage, so the higher location was required. When converting Pro Stock to EFI, officials will have to address similar issues of hardware and software.

What’s first, EFI or hood scoops?

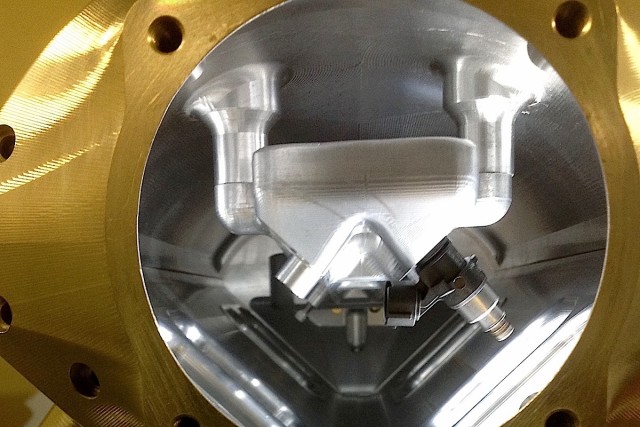

Here’s a more exotic example of injector placement. This is a custom intake for a twin-turbo small-block built by RC Performance Engines in Australia. Note the injector is positioned in the plenum just above the mouth of the intake port. Would NHRA allow this type of technology?

But we’re probably putting the chicken before the egg. Finalization of air inlet guidelines should come after deciding where the air is going.

Converting Pro Stock engines to EFI won’t be unusually difficult, given the wealth of information gained from running fuel injection in Pro Mod and other drag classes as well as outside contributions from road-racing and oval-racing disciplines.

This is a move that should have been made 20 years ago, and NHRA is finally catching up to the real world. But sometimes old habits are hard to break because rule makers are hesitant to re-establish boundaries for the engine builders. A quick list of the obvious concerns would be:

- What size and how many throttle bodies?

- Location of the throttle bodies?

- Butterfly throttle bodies? Or will slide throttle bodies be permitted?

- Will knock sensors be allowed?

- How many Lambda sensors allowed?

- One or two injectors per cylinder?

- Sealed spec injectors, or can teams modify internals and spray patterns?

- Injector location? Mounting bung required on the outside of the runners, or allow installation in the plenum above the runner mouth?

- And the big one, of course, which ECU will be required?

It would be a disaster to allow teams to install the ECU of their liking. A strong role model for changing over to EFI can be found in NASCAR. Officials there worked with McLaren and Freescale to design an ECU with powerful firewalls and encryption that would prevent teams from tampering with the available controls and data acquisition. Tuners should be allowed to adjust spark timing and fuel delivery, but not have the freedom to create channels for facilitating traction control or adjusting the fuel/spark to introduce illegal power enhancers–such as nitrous oxide or propane–to the engine’s environment. NHRA has previously addressed traction control with a required MSD ignition box that has been programmed to detect dishonest traction-control maneuvers.

NASCAR has the ability to download and evaluate all the power data from every team’s ECU to ensure that the rules as well as the spirit of the rules are followed. The sanctioning body also established strict hardware requirements with throttle body size, spec injectors and required placement. You may have noticed that the injectors are positioned quite high on the runners. Engine builders will quickly admit they’d rather see injectors closer to the intake valve. However, NASCAR testing revealed some cylinder heads had a measurable advantage over the competition with a conventional injector location. So NASCAR required injectors for all engines to be mounted high on the manifold runners.

Just what will EFI do for Pro Stock engines? Builders will have a little more flexibility in some areas, such as cam timing. With fuel injection there is no worry about generating a strong signal for the carburetors, so more aggressive lobe separation is a possibility. You might not see a noticeable increase in horsepower right away. Matt Hartford of Total Seal converted a Hemi Pro Stock engine to EFI to run Comp about four years ago. In an email to EngineLabs, he said the total cost was close to $25,000 for new intake, fuel pumps, throttle bodies, ECU and other hardware in addition to a week’s worth dyno time to dial in the new setup. Final numbers were one less horsepower and one more lb-ft of peak torque. He also acknowledges that since more Pro Mod tuners have switched to EFI, costs will come down.

As for wheelie-bar length and rev limiters, those topics came up after EngineLabs talked at length with its sources and so there’s little analysis of those subjects. However, from a selfish perspective, we’d like to see NHRA shelve any talk of limiting RPM in Pro Stock engines. How fast a 500ci big-block is turning over is one of those mystical talking points that keeps hardcore enthusiasts on task and generates spirited debate. Where are the drivers shifting? What’s the tach reading in the traps? It’s very reminiscent of Formula 1 in its heyday when Cosworth first spun past 20,000 rpm. There was even talk that teams recorded the sound of competitors’ engines in the straightaways, then washed the digital feedback through sophisticated software to determine an engine’s operating RPM. Keeping rev limiters out of the equation provides a moving horizon for engine builders to pursue as well as a riveting discussion topic among fans. There’s absolutely no need to slow down these cars or their engines.

How much power from blown small-blocks?

On a final note, it’s very likely that the proposal to phase out 500ci engines in favor of supercharged factory small-blocks will generate favorable response and will be heavily debated over the upcoming months. This idea has support from a number of perspectives, including the EngineLabs editor. Starting the class over with a heavily modified Super Stock engine wrapped under factory sheetmetal is a promising idea because of immediate fan identity and a close relationship to today’s automotive marketplace.

The current egg-shaped Pro Stock bodies are an insult to the heritage of the fabulous factory hot rods of the late ‘60s and early ‘70s that started this class, as well as slandering the current Mustang, Camaro and Challenger designs. Morphing Pro Stock bodies back to their factory roots is essential to any revitalization effort. Granted, that’s not an easy plan of action. There are definite differences between wheelbase, overhang, frontal area and other physical factors that separate the competition. But it has to be done.

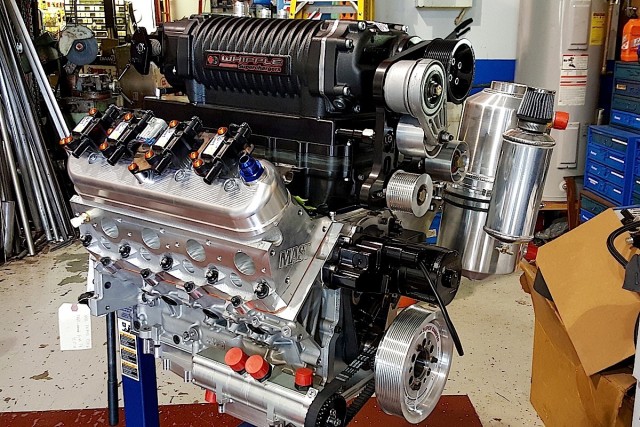

A 388ci supercharged LS engine, like this bullet built for JC Beattie Jr’s COPO Camaro, could come close to current Pro Stock power levels with the right boost.

On the flip side, making power comparable with today’s Pro Stock engine won’t be impossible for the boosted small-blocks. JC Beattie Jr. of ATI Performance Products worked with Shawn Miller at Precision Racing Technologies to build a 388ci LS engine that will go into his COPO Camaro, with a goal of running in Ultra Street or Outlaw Factory Showdown type competition. The bullet is based around a raised-cam RHS block with a Bryant billet crank, GRP rods, JE pistons, Bullet cam and full Jesel timing set and valvetrain. The Mast heads are completed hogged out and fitted with Manley titanium/Inconel valves along with Manley and PAC springs. Underneath is a Dailey 5-stage dry-sump oil system, and on top is a Whipple Twin-screw blower with custom intake and intercooler. Fuel system is a combination of Injector Dynamics injectors and AEM Infinity ECU. Plenty of custom parts had to be fabricated, such as the 12-rib blower drive and 4-trigger cam reluctor.

Here's a view of the custom intake and intercooler built for Beattie's 388 LS engine, and the dry-sump-equipped engine tested in a new K-member before installation into the car.

There has been a poorly thought-out suggestion of simply swapping the modified COPO/Cobra Jet/Drag Pack engines for the 500ci engines in the existing chassis. That’s nothing more than giving the current body style a different exhaust note. It won’t work. Fans of the Factory Showdown movement—those who would be the foundation of renewed interest in a revamped Pro Stock division—have a strong bond with both the factory engines and body styles.

No doubt the new leadership at NHRA can take positive as well as aggressive steps to renew interest and enthusiasm in Pro Stock. Watch for more announcements and spirited debate in the upcoming weeks. EngineLabs may not always be the first with breaking news, but we promise to deliver the deepest analysis of the changes. For a closer look at our comprehensive profile of Pro Stock engine technology, check out this story.

Whatever happens, don’t let Pro Stock morph into Pro Mod. They’re two completely different disciplines and performance strategies.