Our initial viewing of Ryan MacNeil’s 261 Stovebolt engine’s first-fire video piqued our curiosity, so we reached out across the vast open spaces of the interweb to find out more about the project. The Stovebolt is so named because of the inline-six engine’s OE use of 1/4-20 slotted head fasteners in multiple positions – those same bolts are commonly used in the assembly of wood stoves.

It turns out that’s there’s much more than meets the eye to this article, as there often is with engine (and vehicle) restoration projects. The engine is installed into a 1949 Chevy 3100 Deluxe Cab pickup that has become a labor of love. It’s quite a story; follow along, won’t you?

“I first fell in love with these trucks when my Dad dragged home a pristine, Forrester Green, 1951 3100 Deluxe cab barn find back in 1995 after receiving a hot tip from his father-in-law. It was a gem that even had the old 1951 Commercial California license plates still on it. That was it; I was in love,” says MacNeil.

Unfortunately, that project went the way of many others the hot-rodding world has seen, sold off before its completion – but the hook was set for Ryan.

In 2009, after a discharge from 10-plus years of serving his country in the US Coast Guard, MacNeil was in hot pursuit of a degree in Automotive Technology on the G.I. Bill, and was also searching for a project to play with while going to school.

Hours upon hours of searching on Craigslist brought the ’49 Pickup he currently owns into view; it was nine-and-a-half hours away in Oregon, but only a short drive away from where his father was living at the time.

He made the trip, handed over $1,800 to the proverbial “little old lady”, and became the new new owner of a project that, for lack of a better term, was a real project.

“I realized quickly that I wasn’t going to just “get it running” and drive it home like the old lady said would be the case. Every aspect of the truck was beat-down and broken. Literally everything was bad. Body, engine, transmission, radiator, electrical, interior, tires, brakes—everything. The truck’s condition forced me into a complete restoration. In retrospect I don’t know what I expected for $1800 bucks!” says MacNeil.

Humble Beginnings

His vision for the completed project was simple. “I wanted it to appear stock but be heavily lowered and capable of freeway speeds. Low tech, and old school,” he explains.

That vision, in the interest of keeping costs down, originally included re-using the 1954 235-cube engine that has previously been transplanted into the truck, but further inspection ruled out that plan pretty quickly, as he determined that the engine has previously been rebuilt a number of times, and even had a crack in the water jacket to go with the thick black cheese coating everything under the valve cover.

Hopefully we haven’t lost you yet, because here’s where the engine selection comes in. “For me, these Stovebolt engines are a signature characteristic of these trucks. They had an extremely long run in GM’s vehicles and only underwent minor improvements. The interchangeability of parts among the Stovebolt varieties is a valuable bonus as well. The 1953–62 Chevrolet 235 and 261 motors were ideal – they don’t look out of place in the engine bay and they were some of the best versions within the inline 6 motor family,” says MacNeil.

The internet search began anew, and Craigslist again proved the place to be, as he found the engine you see in these photos advertised for $200 as a “1965 235ci” engine.

He double-checked the casting numbers, and realized that he could have a 1957 261 – complete with Siamesed cylinder bores – instead. In fine Craigslist shopping form, he offered $75, made the deal for $80, and went to pick up this engine.

Remember that degree in Automotive Technology he was after? The semester following his acquisition of the engine was – you guessed it – the Automotive Engines course at school. MacNeil persuaded the Program Director/Instructor, Bob Miller, to let him rebuild the Stovebolt in between working on the 383 small-block stroker that was the required learning for the class.

“When I had extra time in between classes, during breaks, and after class, I worked on my 261. I had access to all the machine equipment, hot tank, sand blast cabinet, specialty tools… everything. This situation was an incredible learning opportunity, a financial savior, and most of all, fun,” he says.

External views of the block after cleaning.

Inevitable Issues

Upon inspection, the engine was found to have undergone a rebuild in the past with a .060-inch overbore, but during the inspection, the first issue showed up. There was water intrusion into cylinders 4 and 5 that was rusted too deep to hone away, so MacNeil made the executive decision to order up a pair of sleeves to correct the problem.

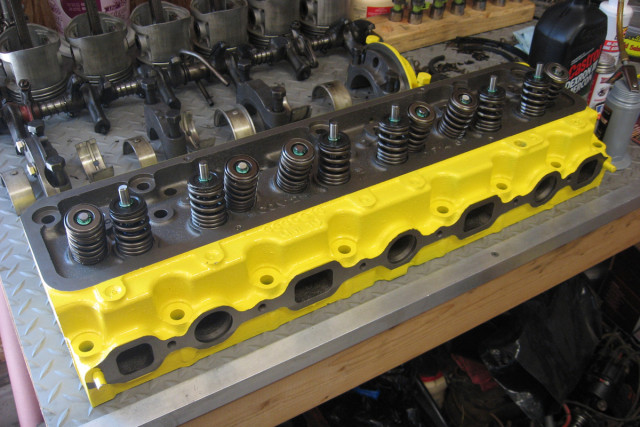

“Throughout my build the cool surprises just kept coming. During the cleaning process I learned another signature attribute of my Jobmaster— when I hoisted the engine out of the hot tank the hot caustic uncovered the original paint beneath its newer Chevy Orange paint job. For one year only, 1957, Chevrolet 261s were yellow. Upon learning that I couldn’t help but return it to its original color. Hence, the yellow paint job,” he says.

And here comes problem #2 – a cylinder head that had cracks in three of the combustion chambers. He had the head that was on the original engine, and yet another 235 that he had picked up for free, so one of those two had to be good, right? You know the answer – of course not!

Instructor Bob located two more donors, which also had exhaust seat cracks, taking the number of boat anchor cylinder heads tested for this engine up to five.

“A couple days later my buddy, Gary Tomlinson, called me. ‘Hey bro, I found not one but two 235 heads for you. I know this old Stovebolt guy who owes me a favor. One of them has to be good.’ The next day I dragged them to school, mentally prepared to pronounce them both dead but what I found was pure hot rod luck – both heads were good! Not one crack,” recounts MacNeil.

The sleeve installation process was part of the fun – four guys including Instructor Bob assisted, one removing the sleeves from the freezer, one holding them steady on the bore, one buttering them up with red loc-tite, and one hammering them home into the block.

“Because sleeves require an interference fit of 0.0005-inch for every inch of sleeve length, I needed a 0.0035-inch interference fit for my 7-inch sleeves, and bored my block accordingly,” he says. “Next I milled the tops of the sleeves flush with the block and decked the block’s head surface, removing 0.010-inch. I then bored and honed cylinders 4 and 5 out to 0.060-inch oversized to match the other cylinders.”

Different views of where the steam holes needed to be punched through the cylinder head deck surface.

Cylinder bore finished out at 3.810-inch with a 3.9375-inch stroke, for a final displacement of 270 cubic inches.

The 235 cylinder head was milled .013-inch to deck it true, but it required some extra precision machining prior to the decking to match up with the Siamesed bores in the 261’s block. Using the head gasket as a guide, MacNeil drilled six new holes into the deck surface to match up with the steam holes in the block and gasket surface to ensure proper cooling.

First Fire

It’s now four years later; the engine was complete and had been sitting in a cart while MacNeil finished his schooling, earned his degree and all of his ASE Certifications.

“I made the decision to finally fire my Jobmaster 261 when my Dad came for a visit over the holidays. So on December 20th, 2014, I finally lit the fuse. The engine had been sitting so long, and I had rebuilt and modified so many things, I was scared ****less something was going to go wrong. With my dad sitting impatiently on a stool behind me he barked, “what the hell are ya waiting for… fire it up!” So I did. We watched the fuel travel from the glass bowl on the fuel pump into the carb, and then she came to life,” he says.

“Using all the information and techniques learned in school, I disassembled, inspected, cleaned, measured, magnafluxed, machined, and rebuilt my 261 powerplant. Almost all the machine work I did on my own with the exception of the installation of the hardened exhaust valve seats and cutting the valve seats. I am forever appreciative for my outstanding instructor, Bob Miller, for allowing me to build my 261 in addition to the class requirements even though he knew it meant more work for him,” sums up MacNeil.

“Using all the information and techniques learned in school, I disassembled, inspected, cleaned, measured, magnafluxed, machined, and rebuilt my 261 powerplant. Almost all the machine work I did on my own with the exception of the installation of the hardened exhaust valve seats and cutting the valve seats. I am forever appreciative for my outstanding instructor, Bob Miller, for allowing me to build my 261 in addition to the class requirements even though he knew it meant more work for him,” sums up MacNeil.

A fun project, a learning experience, and another hot-rodder welcomed into the fold with an engine that’s not your standard small-block. It’s interesting to note that we don’t see a single Stovebolt fastener anywhere on Ryan’s engine.

Click on the video, listen to the 58-year-old engine purr, and enjoy!

If you’re interested in submitting your garage-built engine to Homegrown Horsepower, send a few quality photos and the details to [email protected].