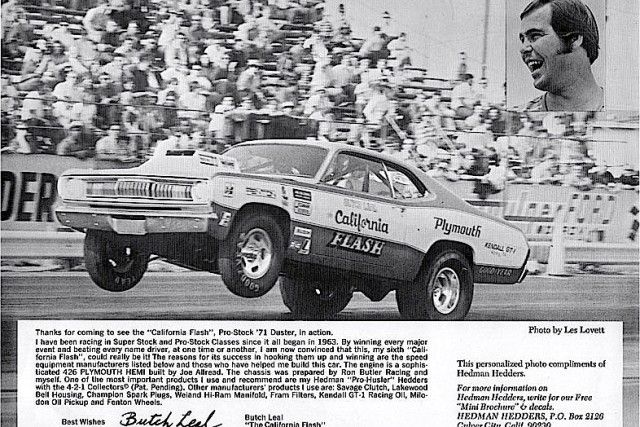

It was recently announced that Butch Leal, one of the best driver/engine builders in the early days of Super Stock and Pro Stock, will be one of eight new members inducted into the International Drag Racing Hall of Fame. Ceremonies are scheduled for March 12 at the Paramount Plaza Hotel in Gainesville, Florida.

EngineLabs cornered Leal at a Ford show last year and talked about Pro Stock motors and other engine-related topics. Here are some of the highlights of that conversation:

EngineLabs: First time in an engine shop?

Butch Leal: I started doing engines in 1963 for Mickey Thompson. He had all the machine equipment at his shop. I did my own milling and cc’ing the heads. To do the heads perfect, it took me about three days. That’s finding the right cc and matching all the chambers to be the same.

Butch Leal was a leading force in the Funny Car movement of the late ’60s. Photo from ButchLeal.com.

EngineLabs: What about camshafts?

Leal: Like everyone else, I had to learn how to degree a camshaft. I was a camshaft person. I used a lot of different camshafts.

EngineLabs: What helped in those days?

Leal: Compression really worked. Officials then started cc’ing the heads. We started sticking the piston out further. Then we had to worry about piston-to-valve clearance. Next you get a bigger cam. Now you have to pull it apart and cut the intake pocket a little deeper to get clearance. It was a never-ending battle when you change something.

EngineLabs: Talk about the Ford 427 low-riser and Thunderbolt engines.

Leal: Not having everything right, it ran 114 or 115 mph. I took it apart and put a lot of compression in it. Got the deck right, put a cam in and it ended up going 121. Only had it about six months and just got it finished when the 427 Thunderbolt came out. It would go 123 or 124. I took it apart after a couple races, bored it .060 over, which NHRA allowed. Also raised the compression and changed the cam. The it ran 128 and no one ever beat me. 10.90 was the best I ever ran with it.

EngineLabs: Enjoy working on the dyno?

Leal: I didn’t get the dyno back then. Mickey was doing Indy cars for Ford, so he had the dyno all tied up. Everything was test and tune, but fortunately Long Beach (Lions Drag Strip) was four miles away and I had the key.

EngineLabs: What’s the difference between Super Stock and Pro Stock?

Leal: In Super Stock you could barely touch it. Pro Stock is a whole different animal.

Check out Butch Leal racing Tony Christian at the 2:18 mark in the video below.

EngineLabs: Remember the first time you saw the Boss 429 heads?

Leal: Mickey helped develop hemi heads for the Ford big-block. They were basically 392 heads with a Ford bolt pattern. That’s all it was, nothing trick about it. We talked with NHRA, we designed a tunnel-ram and Mickey had it poured to fit the 429 head. It was basically a Chevrolet big-block Edelbrock. Buddy Bar poured and machined and got it to fit. I took that engine apart every week trying to go faster. I might try a different hone, a different piston combination. That 429 had two quench areas and a canted intake valve but a huge intake port. I even made venturis for the port to try and figure out how to make it run.

EngineLabs: Was moving over the Chrysler team a difficult transition?

Leal: The 426 and I got along very well. Again it goes back to compression, it liked a lot of compression. I changed the shape of the piston. Learned from Garlits that the fuel cars like a lot of timing. In ‘67 I had an injected funny car. I ran quite a bit of compression for nitro, 13.5:1, and 45 degrees timing. If I backed it up to 10.5:1, I’d have to put 65 or 70 degrees timing. But I like compression. I like a hotter plug because it would hurt the plug before it hurt a piston. Just a lot of trial and error.

EngineLabs: Best engine builder you worked with?

Leal: Joe Allread was probably the best engine builder who helped me. He had built engines for Bill Bagshaw. We built an engine in his garage at the house and the next weekend I set both ends of the Pro Stock record. Again, it goes back to compression. I just raised it a little. I think we were at 14.5:1, and I made it 15.4:1. When you’re pushing the compression, you can’t hear the pinging with the headers, but you can feel it. Today the Pro Stock engines are moving to smaller combustion chambers with bigger valves, and the timing has gone from 36 degrees down to 26 or 27 now.

EngineLabs: Any tricks involving oil or fuels back then?

Leal: We’d drain the transmission if we got into the final and use just the oil that had soaked into the discs in the Lenco. Eventually we got down to 5W and then Mobil 1 synthetic came along. Today I know they have a lot of trick oils that I know nothing about. We used aviation gas in the mid-‘70s. Once in while we put more lead into it. We got around 120 octane.

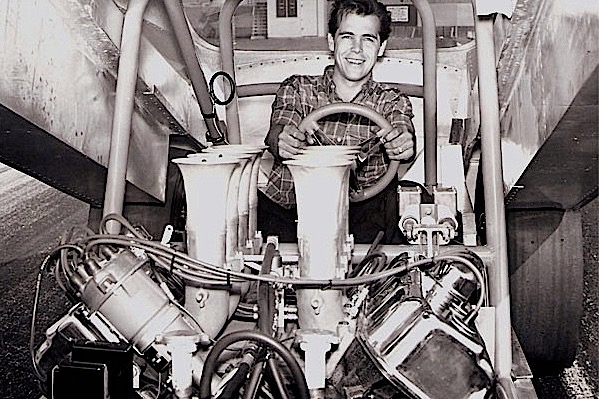

Leal worked on both nitro injected and Pro Stock Hemi engines. Photos from Butch Leal collection and Mecum Auctions.

EngineLabs: Talk about the changes in Pro Stock today.

Leal: We didn’t have the blocks they have today. They’ve raised the cam location as they’ve designed new motors. Heck, the cam bores are bigger than the main bearings. They’re all using Honda bearings. We were kind of going in that direction. At Pontiac we came up with a roller cam bearing. Today, running those short, fat pushrods because of all the spring pressure. They’re turning 10,700 rpm with a pushrod! I was turning mine 9,200 to 9,300, and that was 400 more than anyone else.

EngineLabs: Think back to the best engine development in those days.

Leal: We did head work to move the ports to get straighter pushrods. With a lighter rocker we picked the engine speed up. But as all this was happening, we started shortening the deck height. If you look at a Pro Stock engine today, you’d swear it was a small block because the deck height is so far down compared to what we ran.

EngineLabs: Where did you shift?

Leal: Around 9,200 rpm.

EngineLabs: And what was the most horsepower you made on the dyno?

Leal: Hit 1,170 at Reher-Morrison one time. But I had to lower it down because it wasn’t making much torque.

Remember dry hops? Check out Leal at OCIR in the early ’80s!

EngineLabs: Pro Stockers are closing in on 1.2 inches of valve lift. Where were you?

Leal: Probably .860 was the most I ran.

EngineLabs: Any other thoughts on Pro Stock valvetrains?

Leal: Every run we changed valve springs. Back then I was getting free springs, so we’d change them every run. One time we had an engine that was 70 to 80, maybe 100 horsepower down from our good one. Got to the final at Gainseville against Glidden and the good engine didn’t feel right, so we put the other one in. We won and ran quicker than the engine with a 100 horsepower more. We finally figured out after all these years why. It was the engine with with the straight rockers and straight pushrods. The other one had offset rockers but the intake was straighter for power, which the engine liked. But then the valvetrain went to crap. It might have been down a 100 peak horsepower, but it would accelerate quicker to 9,000 rpm.

The Hall of Fame is located in the Don Garlits Museum of Drag Racing in Ocala, Florida, and the induction ceremony precedes the NHRA Gatornationals. Other inductees include Lee Edwards, Shirl Greer, Jerry Gwynn, Bob Muravez, Bill Schultz, Jess Van Deventer and Dave Densmore, who will receive the Founder’s Award. Of note to EngineLabs readers, in 1971 Schultz tuned the last front-engine dragster to win a NHRA Top Fuel title.

You can learn more about Leal’s career and see more photos on his website.