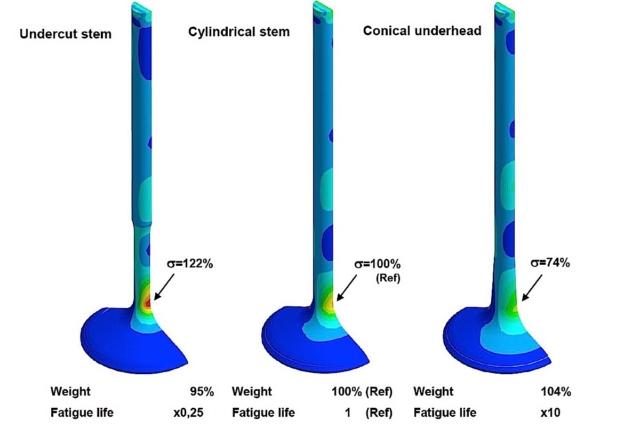

Different detail geometry, such as a waisted stem or conical head form, has a major influence on the stress distribution.

An often overlooked aspect of valvetrain operation is that one side of the valve usually contacts the valve seat ahead of the remaining sides during the closing event. This action introduces heavy loading on the valve stem. If there’s a high degree of forced induction through superchargers or turbochargers, the load values can increase.

To better understand these actions, Federal-Mogul Powertrain developed a simplified transient simulation model of valve-closing action to help predict the dynamic loading on engine valves.

A test rig developed by Federal-Mogul Powertrain enables actuation of a single valve as well as the evaluation of individual closing events.

“The dynamic loading during valve closing is a decisive factor in designing intake and exhaust valves,” says Gian Maria Olivetti, chief technology officer for the group. “With the new simulation method, we can quickly calculate the maximum expected valve loads, thus saving time and ensuring targeted development.”

The computer tool will be most helpful when designing valves for production engines under fast track development. A simplified simulation model limits valve loading evaluation to the main parameters such as valve closing speed, valve spring return force and the clearance between the valve stem and guide. The dynamic simulation model of the closing event, as developed and tested by Federal-Mogul Powertrain, enables precise calculation of the loads; that, in turn, allows components to be configured optimally from the concept stage and life span to be determined more accurately.

“Different detail geometry, such as a stem undercut or conical underhead, has a major influence on the stress distribution,” explains Dr. Guido Bayard, director of technology for valves in the powertrain division. “With our simplified FE simulation, we can quickly draw conclusions on maximum valve loading and likely fatigue failure, and make sound decisions on design and material at an early stage of development.”

Results from the simulation model have been confirmed by practical testing. Federal-Mogul is the parent company to many popular brands, including Fel-Pro gaskets, Champion spark plugs and Sealed Power engine components.