Ryan Falconer has engineered himself into a position in the running for the title, boutique engine builder of the century. He has built powerplants for a plethora of go-fast applications — IndyCars, powerboats, desert racers, airplanes and more. Throughout his nearly 60 year career he has introduced new designs and engines to market, and supplied powerplants to machines piloted but a laundry list of A-listers from the racing world.

Ryan Falconer has engineered himself into a position in the running for the title, boutique engine builder of the century. He has built powerplants for a plethora of go-fast applications — IndyCars, powerboats, desert racers, airplanes and more. Throughout his nearly 60 year career he has introduced new designs and engines to market, and supplied powerplants to machines piloted but a laundry list of A-listers from the racing world.

Roger Penske, Keke Rosberg, Paul Newman, Jackie Stewart, Parnelli Jones, Mario Andretti, and Al Unser are among the drivers to race under Falconer power. This is a man who eats, sleeps, and breaths engines, we couldn’t pass up an opportunity to talk to someone who has left a legacy of horsepower and torque across the motoring landscape as far reaching as Ryan Falconer.

Clockwise from top left; Al Unser, Keke Rosberg, Mario Andretti, Jackie Stewart.

“My whole start in racing was building engines with my brother for drag racing when I was 14 years old. As far as my racing involvement goes — I went to work for Paxton Products in the late part of ’61, and the Granatellis had bought the Novis. I started right out at Indy in ’62 working with Gene Marciniak on the Novis, Gene quit and I ended up taking over the engine building program in ’64. I had a disagreement with the Granatellis and went to work for Shelby, while building engines on the side for Can-Am. Shelby didn’t like that, so I quit and started my own business,” Falconer reminisced with a chuckle.

Starting out engine building with the in-crowd certainly went a long way towards endorsements for future projects, the network of friends and contacts Falconer was able to accrue opened doors that he gladly walked through. Demonstrating a penchant for for his craft, Falconer’s passion shined through and he gained a following of drivers that made it contingent he build the engines for their rides.

“It was in the early ’70s that thing really took off because of a guy named Jim Chapman, who worked on the Lola car at the speedway we won the race at — he’d built Lola cars for years. Jim was hired by Parnelli to run the new Formula 5000 team — once again I got a really nice endorsement to build the engines. We did that ’73, ’74, ’75, we started out with Mario Andretti and Al Unser, we had good success,” Falconer continued.

With a proven track record and rolodex full of contacts in the racing world, Falconer’s business grew into major GM research and development. “I contacted General Motors about doing some work with them — they basically said ‘we don’t use outside vendors,’ and then I continued to do work for them for the next 25 years,” Falconer laughed. “I did a lot of development work for them on the outboard stuff — the V6 that Larry Ragland won Baja with a number of times.”

The V6 scream of the modern IndyCar is a direct descendant from Falconer’s contribution to the open-wheel race scene. In the 1980s Chevrolet called him to ask the feasibility of racing Indy with a V6, he answered why not. With a shipment of GM parts, a deadline of mere months, and a shoestring budget Falconer and his team turned out a complete engine and an additional short block to take racing.

“We went to the speedway and ran quick enough to sit on the front row. We took the very first Chevrolet V6 engine to Indianapolis. That’s what started the whole V6 craze,” Falconer exclaimed proudly.

Independent Projects

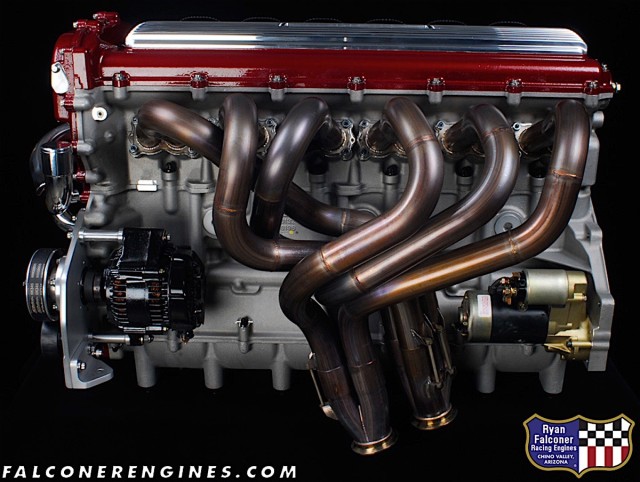

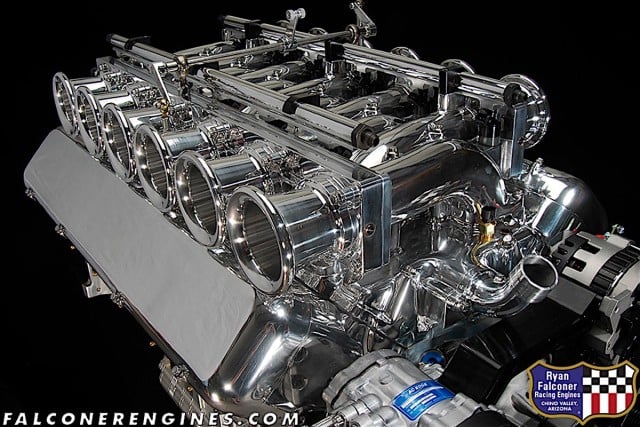

The engine which is perhaps most associated with Ryan Falconer is his V12, not a mishmash, or welded-block special, but a true all aluminum common-crank engine. The idea stemmed from his long involvement with the Indy V6s. “In 1979 a friend of mine, Dave Zucchio, called me and said why don’t we take two of your turbo V6s and mount them together in an airplane,” recalled Falconer.

The engine which is perhaps most associated with Ryan Falconer is his V12, not a mishmash, or welded-block special, but a true all aluminum common-crank engine. The idea stemmed from his long involvement with the Indy V6s. “In 1979 a friend of mine, Dave Zucchio, called me and said why don’t we take two of your turbo V6s and mount them together in an airplane,” recalled Falconer.

With the popularity of Rolls Royce Merlin engines in war-bird aviation and boat racing, a modern V12 was an enticing project for an ambitious engine builder. “I had always loved v12s because my dad had old Packards and Cadillac V12s because there were so many kids in our family they were the only cars you could fit us all in. I thought well, I’ll just built a V12 — but I don’t want to put two engines together, I’ll build a common-crank V12,” explained Falconer.

Drawing on all his GM sources and contacts, Falconer set out to design this unique platform. He didn’t want to build a big lazy engine like some kind of glorified tractor, Falconer was after power-to-weight, and efficiency in packaging. For this he turned to the classic design of the Chevy small block.

“My whole idea when I first started was to build a large-cubic inch engine in a small package. I didn’t want to build a big-block, because it was just too God-damn big! I went with the small-block architecture. I left it at 90 degrees because I didn’t want a tall engine — it made more sense using what was available at the time,” Falconer announced.

“My whole idea when I first started was to build a large-cubic inch engine in a small package. I didn’t want to build a big-block, because it was just too God-damn big! I went with the small-block architecture. I left it at 90 degrees because I didn’t want a tall engine — it made more sense using what was available at the time,” Falconer announced.

The manufacturing of a low-production boutique engine is not trivial, allocating the resources and manufacturing infrastructure is made to sound trivial by Falconer, but his decades of experience and industry contacts helped him to make the design a reality. Falconer builds his V12s in the displacement range from 6.5 to 9.8-liters — they weigh in at 500-pounds, and feature dry-sump lubrication.

“I made patterns for everything, all my castings were done at Eck Industries in Manitowoc Wisconsin — they’ve been doing Chevrolet stuff for years, they pour tons of aluminum. The machine shop was Schwartz Machine in Michigan — everything was through GM connections, so my blocks and heads were made in Michigan, and the smaller stuff manifolds, valve covers were done out here on the coast,” Falconer relayed.

Of course there’s no sense in re-inventing the wheel when it’s not needed, for this many of the internals are produced by mainstream vendors for Falconer. Crankshafts are produced by Sonny Bryant, camshafts by LSM, connecting rods by Carillo, CP pistons, and even the timing chain and gear set from a SBC is repurposed. In addition to the obvious custom castings like block and heads, Falconer built his own rocker-arm assemblies — investment casting them out of 17-4 stainless steel.

Of course there’s no sense in re-inventing the wheel when it’s not needed, for this many of the internals are produced by mainstream vendors for Falconer. Crankshafts are produced by Sonny Bryant, camshafts by LSM, connecting rods by Carillo, CP pistons, and even the timing chain and gear set from a SBC is repurposed. In addition to the obvious custom castings like block and heads, Falconer built his own rocker-arm assemblies — investment casting them out of 17-4 stainless steel.

“I ran the first prototype engine in September of 1980, then one year later I had the production engine done. We originally wanted to go into off-shore powerboat, we got homologated and everything but they wanted us to give them engines. I was contacted by Dan Denny at Thunder Mustang, our engine fit perfectly in their 3/4 scale P-51, so I ended up building 26-28 engines for those,” Falconer explained.

Photo source: Thunder Mustang

The homebuilt Thunder Mustang is the most widely known application for the Falconer V12. A scaled down version of the prolific World War Two fighter — the Thunder Mustang features modern composite construction, and the all-aluminum Falconer powerplant with bespoke MoTec electronic controls.

Aside from the glorious V12 Falconer’s GM connections kept him in the loop to special projects that would have otherwise gone to the scrap heap. Eyeing the potential in these opportunities Falconer took the reigns and picked up where GM left off.

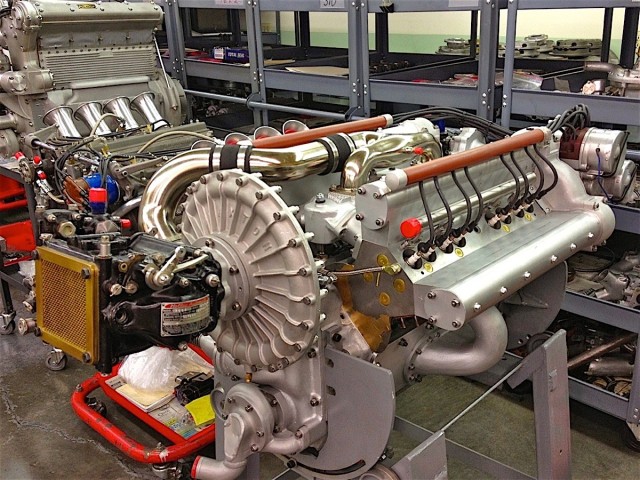

“My future plan was to build a double over-head cam V12. General Motors had built an inline-six for Pike’s Peak — it ended up in the car that Larry Ragland drove, it was a really bitchin’ engine. Through my connections I found out they were going to crush it so I put in a bid, I bought all the inventory they had. My original plan was to build a V12 using two of those heads, I never got to do it but I still plan to. I built that engine into various forms for cars and boats — the L6,” Falconer remembered.

“My future plan was to build a double over-head cam V12. General Motors had built an inline-six for Pike’s Peak — it ended up in the car that Larry Ragland drove, it was a really bitchin’ engine. Through my connections I found out they were going to crush it so I put in a bid, I bought all the inventory they had. My original plan was to build a V12 using two of those heads, I never got to do it but I still plan to. I built that engine into various forms for cars and boats — the L6,” Falconer remembered.

The L6 Falconer engine has been adapted into many forms for all sorts of vehicles. Accompanied by forced induction, or otherwise artfully designed induction systems, these engines can make up to 700 horsepower on pump gas.

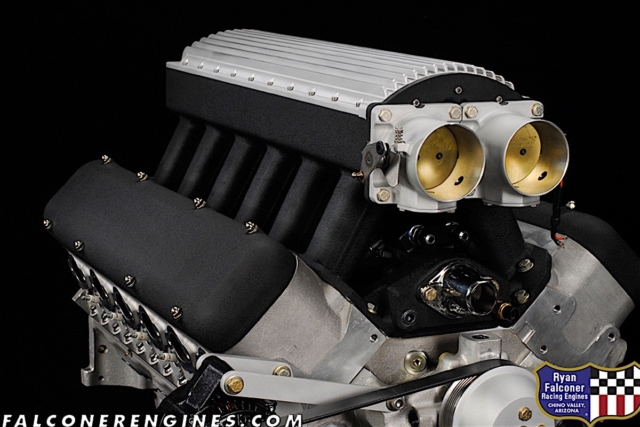

If you just have to have a piece of IndyCar history and technology in your ride, Falconer can help you there too. Having purchased a score of 2002 IRL Indy engines, he is now re-configuring them for street use in specialty applications like hot-rods and performance track cars.

“I made a new manifold, put a supercharger upside down in the middle of the valley, drove it off the back of the engine and made a nice little street engine that would run 700 horsepower on pump gas and rev between 2,000 and 8,000. I’ve got one in a Cobra, Chip Foose now has one in a ’55 Corvette, and another one I’m building for an Australian customer right now,” explained Falconer. “The beauty is it’s only 3.5-liters, I change the camshafts to my own profile, change the pistons to drop the compression, I only run a maximum boost of 12-pounds and with a really nice intercooler in it they run sweet.”

“I made a new manifold, put a supercharger upside down in the middle of the valley, drove it off the back of the engine and made a nice little street engine that would run 700 horsepower on pump gas and rev between 2,000 and 8,000. I’ve got one in a Cobra, Chip Foose now has one in a ’55 Corvette, and another one I’m building for an Australian customer right now,” explained Falconer. “The beauty is it’s only 3.5-liters, I change the camshafts to my own profile, change the pistons to drop the compression, I only run a maximum boost of 12-pounds and with a really nice intercooler in it they run sweet.”

What’s In Store For The Future?

Ryan Falconer is riding the momentum of his engine building success into pseudo-retirement. His career in the racing world having prepared him to continue to develop some of the most intriguing small-batch engines out there. “Five years ago, I finally decided I’d had enough with employees and all that sh*t — I moved to Arizona where I work in the shop by myself and I love it. I’m still doing the V12s, I’m doing one right now for Kindig-it Design,” Falconer summed up.

We sure hope to see some of Falconer’s creations in person one day, whether they be on land, sea, or in the sky his engines are sure to merit a double take. “I’m 75 years old, I’ve had a long career. I have no intention of stopping, I just love engines, that’s my passion!” Falconer concluded.