Anytime an aftermarket company pushes the boundaries of what was once thought to be the ragged edge of an engine’s architecture, a lot of time, money and effort goes into the project — not to mention an industry reputation being on the line. EFI University has teamed up with COMP Cams to develop an LS-based cylinder head and valvetrain combination capable of revving beyond 11,000 rpm! They call it Project Spinal Tap.

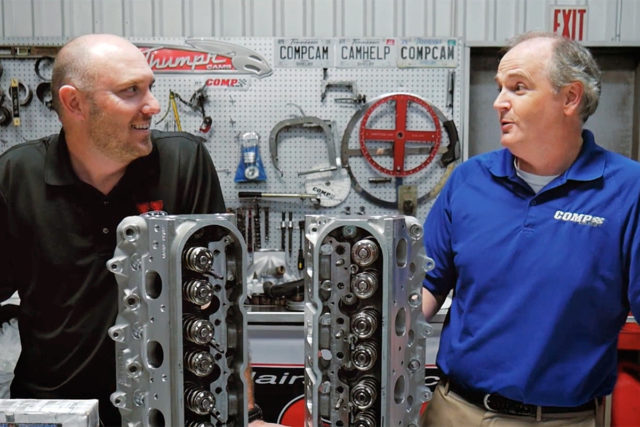

Ben Strader (left), owner of EFI University, and Billy Godbold (right), COMP Cams’ lead valvetrain engineer and physicist.

In the name of exploring the unknown and expanding industry knowledge, Ben Strader, owner of EFI University, shared with us his recent trip to COMP Cams’ headquarters in Memphis, Tennessee, for some experimental SpinTron testing and R&D work with COMP’s own Physicist and Engineer, Billy Godbold.

“Because of the past work I was able to do in Pro Stock, it really opened my eyes to a whole other side of engine development,” says Strader. “Of course the LS is an amazing engine platform, and with the advent of these cheap Chinese turbochargers that are now a dime-a-dozen, it’s very easy to make a lot of horsepower for not a lot of money, even just working out of your garage.”

“The issue for EFI University then becomes, if everyone is able to easily make 700 horsepower, it really negates the need to even have an engine development course on the platform,” states Strader. “So my thought was to take Pro Stock technology and port it over to a platform with a wider audience, like the LS, which is an extremely difficult task to ask of any engine platform. Which is demanding very high RPM and very high compression.”

Introducing Project Spinal Tap

Using high-end technology borrowed from the Pro Stock engine program, EFI University is determined to develop an LS-based valvetrain combination capable of rotating over 190 times per second. But the end-goal is to produce the information to back up their claims – meaning that the methods used have to produce meaningful data that can be used to further improve the design of a system and further the valvetrain industry’s knowledge as a whole.

“About a year ago I started talking with Billy Godbold at COMP and asked him what he thought about the idea, and he bit into the idea like a rabid dog,” Strader jokes. “Billy was the real motivation behind us continuing this project, because without his help, developing a valvetrain design using trial and error would have been way outside of our budget.”

“Through Billy we were able to get in touch with his contacts at Jesel, and they developed a rocker arm system for us that is truly one-of-a-kind, and is what kept the project moving forward,” says Strader. “Even Jesel claims that it is the most stable valvetrain system they have ever designed for the LS platform.”

As stated by Strader, the top-end build itself is a Competition Eliminator-style valvetrain assembly — consisting of a set of RHS Pro Elite LS7 cylinder heads capable of moving 307cc of air, Jesel 0.937-inch keyway lifters, custom Jesel rockers, and titanium valves. The heads sit on top of a sub-400ci Dart LS Next block. The goal is for the project to eventually be dropped into a Fox-body Mustang for no-prep grudge races and bracket events.

“So the goal then became to do something that not just anyone could do. Not only to showcase the abilities of COMP Cams and EFI University, but to most importantly show that there is still more for people to learn about these platforms,” explains Strader. “If guys like me and Billy Godbold are still experimenting and learning new things, our goal in sharing this information with the public is to engage fellow enthusiasts and help them realize that there is still so much more to learn! We’re essentially attempting a difficult project, just for the sake of it being difficult.”

Anytime a project of this magnitude is taken on, a lot of planning and custom machine work has to be completed. With no guarantee everything will work as planned.

“Our biggest challenge initially was the cylinder head. When you start dealing with over an inch of valve lift the rocker arm travel is so drastic that you have to be very mindful of pivot length, which is the distance from the trunnion to the roller bearing,” states Strader. “The longer you can make that arm, the less horizontal distance it will travel through its one inch of arc. In order to have a reasonable rocker ratio, as you make the pivot length longer you have to make the rear longer as well, or else you will end up with a really crazy rocker ratio.”

“The issue this presents for the LS is that the cylinder head itself is very narrow, so Jesel came up with the idea to twist the intake rocker in order to move the pushrod away from the port. Then we also had to come up with a custom titanium valve that was long enough for one inch of lift but wouldn’t make contact with the seals,” says Strader. “But once we got those roadblocks figured out, then we really started to focus on the stability of the valvetrain and how we were going to make it survive. And not just the rocker arms, but the pushrods, lifters and camshaft too.”

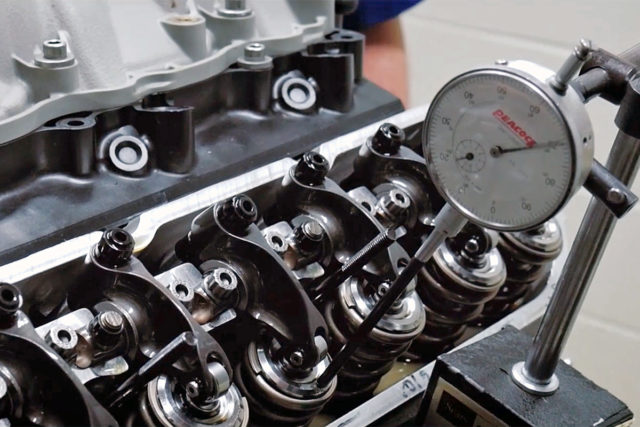

“We have nearly 1,250 pounds of open spring pressure, and while at COMP we found out that with a standard 55mm LS camshaft and standard 0.842-inch lifters, we lost .046-thousandths of an inch of lift due to the severe deflection and bending in the system,” explains Strader. “Think about it this way, if we have a 2:1 rocker ratio and experience camshaft flex of .005-thousandths of an inch, that rocker ratio amplifies that bending to .010-thousandths of an inch!”

Why The SpinTron Is A Valuable R&D Asset

The SpinTron from Trend Performance varies from your standard engine dyno by having the ability to run durability testing, component failure analyses, and frictional horsepower tests on virtually every valvetrain component. Using an alternating current (AC) electric motor to bring the rotating assembly up to speed, the SpinTron will then analyze the valvetrain system through a precision laser camera to track valve motion and pushrod characteristics.

“We started with all standard spec LS parts for phase one of this project. Using the SpinTron at COMP, we were able to see that at around 10,200 rpm there was so much force that the lifter would actually squeeze the oil out from between the bore and lifter, causing galling and welding,” says Strader. “To mitigate that, COMP reached out to RHS to have one of their race blocks assembled with 0.937-inch bushings. Then for phase two, we will be able to run this aggressive Jesel lifter system in combination with a 60mm camshaft core.”

“At that point we are confident that we will reach our 11,000 rpm goal. From there phase three will involve final assembly and running the finished project on our dyno at EFI University,” states Strader. “There’s really no point in running this setup on the engine dyno until it passes on the SpinTron. Believe me, if you break off a valve head on the SpinTron it’s almost funny. If that happens on an engine dyno, not even a crime scene investigator would be able to tell you what went wrong first.”

Will the new RHS setup be able to break the 11,000 rpm threshold and stay together? Stay tuned for more Spinal Tap updates from EFI University in the near future to find out!