While more technical information about the ground-breaking Mercedes-Benz pushrod V8 that won the 1994 Indianapolis 500 can be found in other sources, a thorough and gripping narrative of the engine’s backstory and development is worth a read in the book “Beast” by Jade Gurss.

Codenamed 265E, the engine was developed from scratch by Roger Penske and Ilmor after USAC revised rules addressing pushrod engines and took out the “stock block” requirement. Gurss does an excellent job of capturing the turmoil that IndyCar racing was experiencing at that time. As veteran open-wheel fans know, it all eventually led to Tony George and the Speedway breaking away from CART to form the IRL. George was frustrated that factory engine leases were keeping upstart teams from racing at the 500.

Codenamed 265E, the engine was developed from scratch by Roger Penske and Ilmor after USAC revised rules addressing pushrod engines and took out the “stock block” requirement. Gurss does an excellent job of capturing the turmoil that IndyCar racing was experiencing at that time. As veteran open-wheel fans know, it all eventually led to Tony George and the Speedway breaking away from CART to form the IRL. George was frustrated that factory engine leases were keeping upstart teams from racing at the 500.

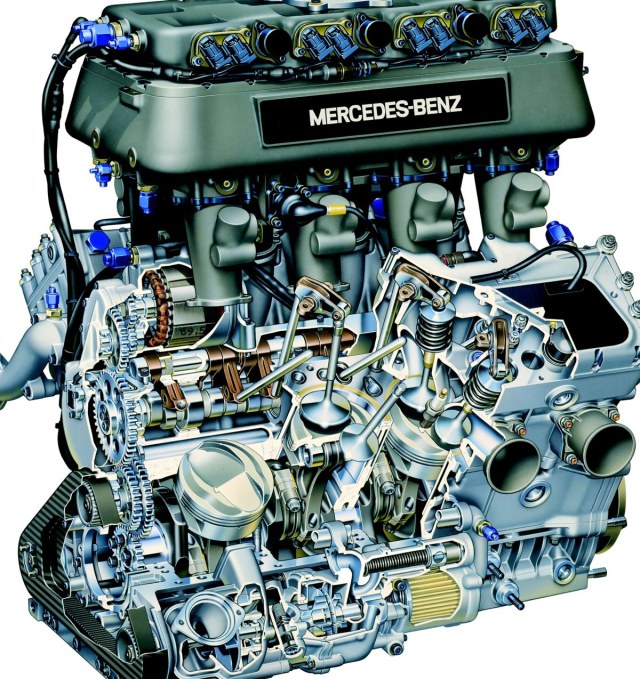

Penske, who was a part owner of Ilmor, was notorious for dissecting rulebooks. Pushrod engines were allowed more displacement and boost than the Ilmor-built Chevy D and Ford Cosworth XB – both turbocharged 2.65-liter V8s that were limited to 45 inches of manifold pressure. The only pushrod engine running those years was the Buick turbo V6, which was powerful enough to get on the pole but could never finish a race. The pushrod engines were allowed 3.43-liters of displacement and 55 inches of manifold pressure.

Rules loophole

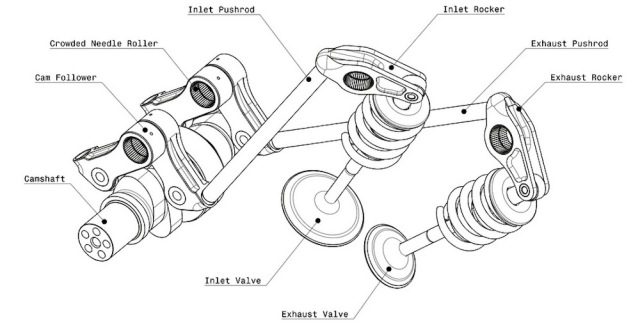

Note the unique valvetrain arrangement using cam followers mounted on a shaft above the cam in place of valve lifters.

Chevy was moving away from Ilmor, so that opened the door for Penske to convince Ilmor’s leadership to build an engine just for the Indy 500, as CART had no similar loophole in its rules. Gurss is very deliberate to emphasize the secrecy that surrounded this project. Apparently, a team owner had kept a previous Ilmor engine and sent it to Alfa Romeo for reverse engineering when the Italian automaker tried its hand at open-wheel racing. Ilmor, therefore, didn’t want any word leaking out that it was building a new engine, let alone exploiting a recent rule change. That was because USAC had the authority to change the boost levels and effectively ban the engine before it even started.

There’s was also a sense of urgency, as Ilmor had less than a year to design, build, test and tune a completely new engine in an era when CAD software and computer simulation were in their infancy. Mario Illien literally sat at a drawing board to spec out the initial design. Adding to the tension was the need for a platform that would fit in the Penske PC23 chassis with no modifications. That meant not only bolting up to the gearbox but also keeping all the plumbing and wiring in place. This engine would not be allowed in other CART events, so the 2.65-liter Ilmor had to come out after the opening races and go back in after the Indy 500 to finish the season. The pumps, coolers and electronics could not be modified to accept the new engine. Ilmor did alter the V-angle of the block, narrowing it up from 82 degrees on the 265D to to 72 degrees. This allowed a higher camshaft position and shorter pushrods.

Tricking suppliers

Ilmor couldn’t do all the work in house, so a few tricks were needed to keep suppliers from learning about the engine. For example, the valve size would be much larger for a 2-valve engine than an overhead-cam 4-valve. So how could Ilmor order these bigger valves from Del West without raising suspicion? They had Penske’s NASCAR team order valves for a Pontiac development engine!

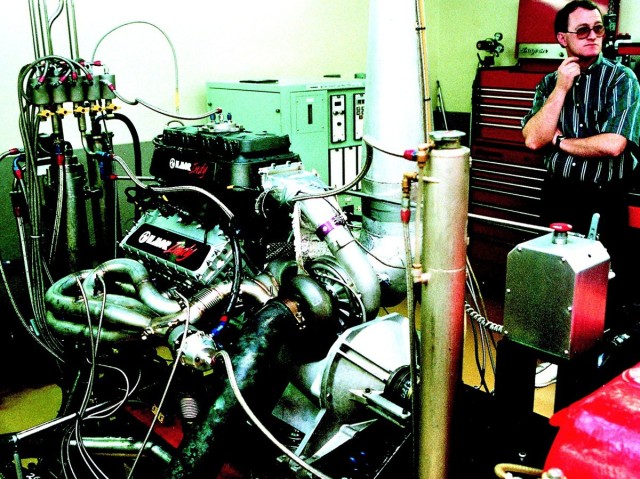

The engine went from drawing board to race track in less than a year.

Ilmor had never designed a pushrod engine, and the key to this design was a unique and very complex valvetrain layout. Instead of lifters riding on the cam lobes, Ilmor came up with cam followers that were hinged on a shaft just above the cam. The followers rode on the cam lobe and offered a light leverage advantage to the pushrod. Since Ilmor had no cylinder heads or blocks for testing, engineers built a 2-cylinder cam rig to test the angles, spring pressures and other gear. It was crude, smoked a lot and flung oil everywhere, but it gave the team a sense of where weak points were and what was needed improvement.

Gurss goes into deep detail as the engine comes together with the help of loyal suppliers and many sleepless nights. He offers insight into how the problems were solved as well as keeps the reader informed of the political and industry events that shaped that emotional and cultural atmosphere of the time. This was a tense period with George setting the stage for a new series that would cripple open-wheel racing. At the same time he had some progressive ideas that would help encourage new teams and open up the engine-building arena to mom-and-pop shops with the Oldsmobile and Nissan engines. But as we all know, George later caved into factory demands and the leased engine program returned under Toyota and Honda.

Massive horsepower jump!

Just as the hardware for the 265E was finalized, the team ran into a problem with the engine management system. They had always relied on a Delco ECU, but for some reason it couldn’t adjust to the 72-degree firing angle. Ilmor commissioned a new electronics startup to design an ECU. Even with that improvement, the engine was making only 850 horsepower against goals of 900 to 940. One engineer suggested softening up the cam profile. Management didn’t agree, but the engineer took matters into his own hand while the boss was away on an annual ski trip and ground a new camshaft. The improvement was 120 horsepower on the first dyno run! The engine was cranking out 970 horsepower, far more than any other powerplant in CART competition.

Building prototype engines and testing on the dyno.

From there, extensive in-car testing was needed to identify weak parts, including secret tests with snow on the sides of the track. The rest of the book follows in detail the engine’s debut at the track, getting it through inspections and the race where Al Unser Jr. won from the pole. Not much drama, as we all know the plot. But Gurss’ story telling and in-depth detail keeps the reader interested.

“Beast” is a engaging read for both engine enthusiasts and open-wheel race fans. It offers an insider’s look at Penske’s very successful management style and the design and manufacturing process at Ilmor – again, very successful. “Beast” is a brisk read at 256 pages and comes with 40 illustrations and photographs. It is published by Octane Press and available for $22.