Increasing engine rpm has a much greater effect on the connecting-rod bolts than many racers may realize, according to Chris Brown of ARP, who spoke Tuesday morning at the Advanced Engine Technology Conference (AETC).

“Don’t assume that bumping up the rpm and you’ll be fine,” says Brown, noting that rpm does have an exponential effect on the connecting-rod reciprocating load.

In one analysis shared with the audience, ARP tested an engine with a 3.4-inch stroke and total reciprocating weight of 2.006 pounds for each cylinder. At 7,000 rpm the dynamic force on the connecting rod was 6,239 pounds. At 7,500 rpm, or a 7.1 percent increase in engine speed, the dynamic force on the rod jumps to 7,163 pounds, or 14.8 percent. At 8,500 rpm the dynamic force is 9,200 pounds. That means the rpm increased just over 21 percent but the dynamic force was more than 47 percent greater.

Connecting-rod bolts are also subject extreme bending loads. As the rod is compressed and stretched, the big-end opening also elongates.

“Basically, the bolt gets bent,” says Brown, “and this bending is concentrated on the inboard side of the bolt.”

That example led to a discussion on the importance of proper tightening of the connecting rod bolts. ARP recommends using a stretch gauge as it’s the most accurate way of measuring preload.

“Luckily with the connecting rod, we have access to both ends and can measure the stretch,” says Brown. “It’s the only guarantee you really have.”

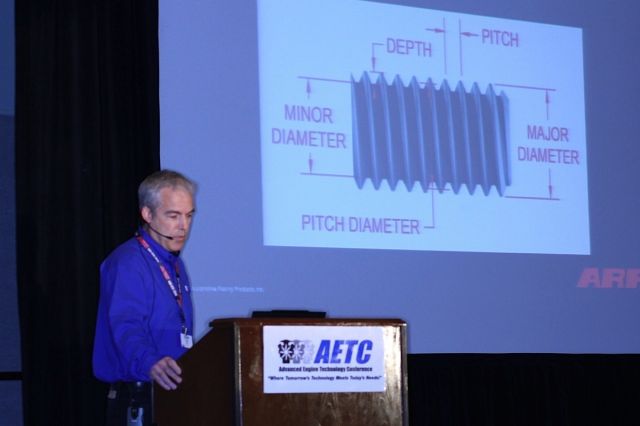

Brown’s presentation continually reminded the audience that fasteners are basically springs that when stretched apply a clamping force.

“That’s the way you should look at all fasteners,” says Brown. “The more extended the spring, the more the clamping load.”

He also emphasized the need for a lubricant that provides preload repeatability and consistency. That’s due to a “friction factor” that changes from the first installation to the next, and different lubricants can affect the number of times a fastener needs to be tightened before it “levels” out the friction factor. That discovery led ARP to develop its own lubricant.

“Proper lubrication will give the same clamping load every time you pull on the torque wrench,” adds Brown.