As manufacturing processes have advanced exponentially over the last few decades with the advent of computer-controlled machinery, so, too, has the business of manufacturing engine gaskets. At the recent AETC event held at the PRI show, Cometic‘s Mark Chollett was on hand to discuss the latest and greatest in engine gasketing materials.

His seminar, entitled “Application of Modern Gasket Technology”, was enlightening and informative, as he covered the basics of multi-layer steel (MLS) gaskets, which are Cometic’s specialty, along with other applications of the MLS technology, custom options, and other gasket materials and applications.

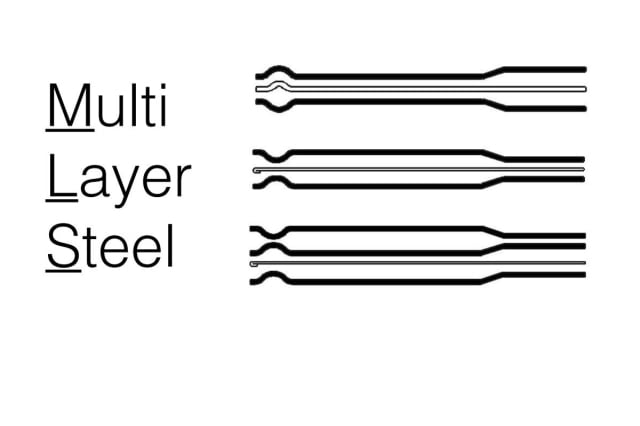

“MLS gaskets are stainless steel or very high quality sheetmetal, coated with Viton or NBR rubber. The geometry of the gaskets are cut, and then the patterns are formed in the material. The geometry formed in the gasket determines how the clamp load is distributed over the gasket,” says Chollett. “The best way to think about an MLS gasket is as multiple springs spread out over the surface of the gasket. There are different magnitudes of springs in different areas of the gasket.”

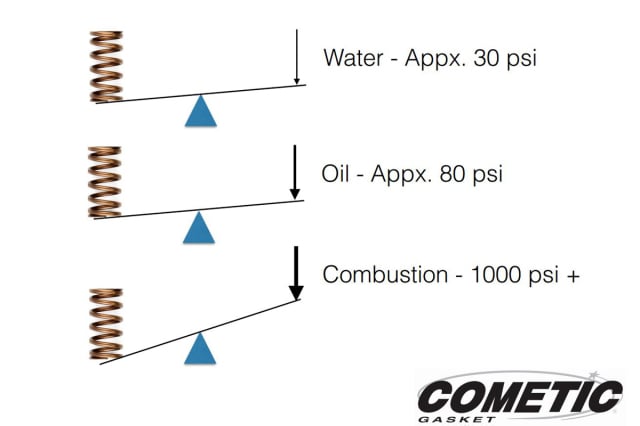

With three separate types of seal required by the head gasket – combustion, oil, and coolant/water, the gasket needs to do different things in different places, thus the varying spring tensions discussed by Chollett.

Coolant pressures can average 30 psi in pressurized cooling systems, while oil can be 80 psi or higher, and combustion pressures reach well beyond 1,000 psi depending upon the type of engine and whether there is an external power-adder contributing to the combustion process. Each type of pressure needs to be exceeded with a safety factor by the gasket design; this requires extensive engineering and manufacturing experience.

Coolant pressures can average 30 psi in pressurized cooling systems, while oil can be 80 psi or higher, and combustion pressures reach well beyond 1,000 psi depending upon the type of engine and whether there is an external power-adder contributing to the combustion process. Each type of pressure needs to be exceeded with a safety factor by the gasket design; this requires extensive engineering and manufacturing experience.

“We’re trying to develop maximum pressure around the cylinders, while taking just enough pressure away from the combustion seal to seal the water and oil pressures,” says Chollett.

He notes that the gasket manufacturer also needs to keep in mind other factors that can be affected during engine assembly that could compromise the ultimate performance of the engine – factors you might not even think of, but ones that Cometic has found to be crucial.

“You can actually concentrate the clamp load to the point where you distort camshaft bearing geometry, or cylindricity of the bores; you can actually clamp it too tight. In a lot of cases we’re trying to seal a highly-boosted engine, with too few fasteners, without distorting anything too severely as to cause other problems.”

As you can see from the styles of gasket depicted in this layout, there are different styles of embossments and varying numbers of gasket layers that are selected for each application, based upon a number of different factors like combustion pressure and type of power-adder.

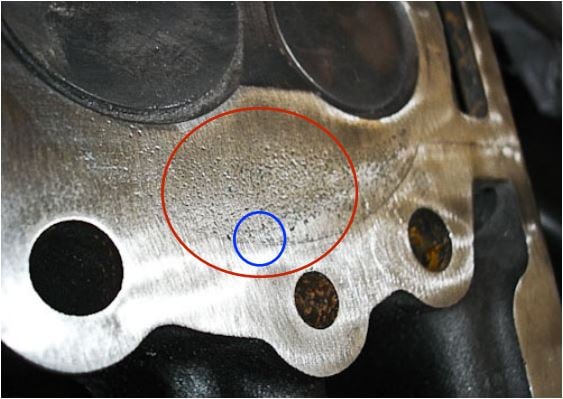

Sealing the block/head area between cylinder bores is one of the largest challenges that the gasket manufacturer faces, as OE engine platforms are constructed to be as thin and light as possible for packaging and other reasons, while performance enthusiasts want to bore an engine as far as possible to achieve maximum performance. Other critical factors important when using an MLS-type gasket are head/deck surface finish, and flatness of the surfaces. The surface finish must be better than 50Ra, and flatness needs to be less than .002-inch across the head and .004-inch down the length of the cylinder head in order for the gasket to properly seal.

On the much-debated topic of spraying an MLS gasket with coatings to help sealing, Chollett says, “The simple answer is no. The gasket is designed with a coating, usually Viton, already on it that can handle high temperature, and each layer is coated to work with the layer next to it where required – the outer layers are always coated. You’re not going to seal combustion with a sealant.”

He does say that if a user feels the need to use a sealant of some sort, then a spray sealant like Hylomar is what’s necessary, as the surface needs to be smooth and consistent. A brush-on product can actually remove clamping force and create a leak instead of repairing one.

Another popular topic is whether an MLS-type head gasket needs to be re-torqued after a heat cycle.

“For general use, the answer is no. They are designed, from the first time they are clamped, to seal the engine properly,” says Chollett.

Surface finish is critical. If the block or cylinder head shows signs of pitting, this must be repaired or replaced before an MLS gasket is used. Serious pitting as shown in this image will not seal with an MLS gasket.

“In a high-boost application, high nitrous, or high output per displacement, then retorquing might help you out. We suggest that you retorque each fastener one at a time; back each nut off 90 degrees and then retorque it, but you don’t want to loosen all of the fasteners at once. Loosening all fasteners at one time, you have a better chance of getting fluid in between the layers and throwing off the torque reading.”

Lastly, he touched on the subject of MLS head gasket re-use.

“A lot of times the question I get is preceded with ‘I read on the internet…’ There are a lot of guys that have re-used our gaskets and gotten away with it, but if you think of the gasket as a spring, when you clamp the gasket, some areas of the gasket are designed to deform at first use,” he says.

Sometimes, the gasket can be re-used when the engine has only been set up on the dyno or in the car and had minimal run time or heat put into the product, but there are pitfalls of which to be wary.

“If you’re using 50 percent of the capabilities of the gasket, you’re probably going to get away with it, but if you’re using 90 percent of the sealing capabilities of the gasket, probably not. You need to consider the cost of the gasket versus potential damage.”