Pulling truck engines are unique in that they require mountains of torque and power that run across a wide RPM range. As the engines are tasked with running in a straight line while dragging along thousands of pounds of dirt in the metal sled trailing the race machine, that wide powerband is useful.

This particular engine is destined for competition across the northern border in Canada at the hands of Barry Wiebe of Wiebe’s Steel Structures. It’s a 611 cubic inch big-block Ford mill designed and assembled by Scott Foxwell at Straub Technologies in Tennessee.

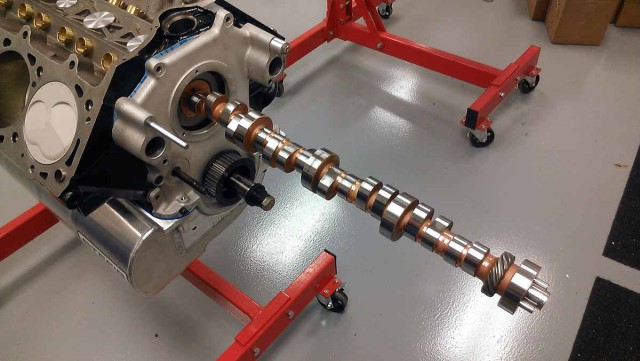

Installing the bronze lifter bushings into the block. Block work was performed by Bob Meyer at Performance Machine in Tennessee.

The Unlimited class is full of trucks with 700-inch-and-larger engines, but Foxwell feels that they can be super-competitive with the smaller-displacement engine given previous experience.

The 60mm-core camshaft was developed by Chris Straub to provide maximum power over a wide rpm range. Straub’s philosophy is to build the right combination every single time – it may not always set the dyno on fire, but on the track his processes have proven themselves in competition.

The engine is based around the best of the best of the aftermarket parts available for the big-block Ford platform. A Premier block from Eliminator Products features a 10.300-inch deck height and siamesed bores, and is delivered complete with billet 8620 steel four-bolt main caps on all five journals. The head-bolt pattern is also designed for 18 fasteners per side to maximize clamping force. In this application, the block has been bored to 4.650-inch per cylinder, and is capable of going larger to 4.700-inch.

The rotating assembly consists of strength personified; a Scat billet 4.500-inch stroke crankshaft is used, swinging Oliver billet I-beam connecting rods ’round. Custom Diamond thermal-coated pistons are also selected for this application, which will run on alcohol fuel.

Oliver, Diamond, and Scat come together in the rotating assembly of this vicious big-block. With the 4.500-inch stroke, clearance in the crankcase is at a premium.

The top side of the program is where it all begins to come together. Foxwell absolutely raves about the Blue Thunder Thor cylinder heads used on this engine. There are two versions of these cylinder heads; a porter’s version and a ready-to-run version. The heads utilize 2.480-inch intake and 1.860-inch exhaust valves and have 75cc combustion chambers.

From bare cylinder head to completed product, with CNC porting performed by Pro Stock wizards CFE Racing.

These heads – the as cast version – were sent to Carl Foltz at CFE Racing to run CFE’s CNC program on the ports and combustion chambers. With the CFE program in place, the head flow is adequate for the engine combination, says Foxwell.

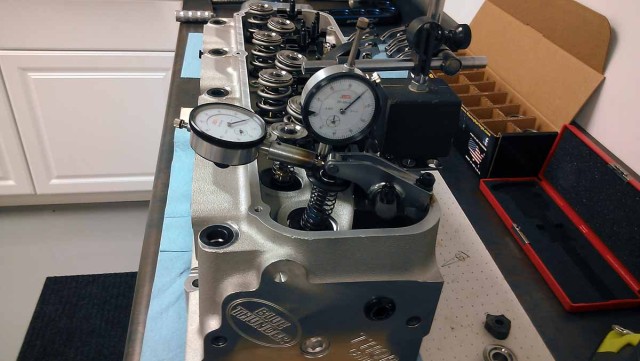

Checking the rocker geometry to ensure proper valve actuation. “Correct rocker geometry is a critical part of getting the valve train correct and making sure the cam’s lobe design is translated as accurately as possible to the valve,” says Foxwell.

“Flow numbers are critical knowledge for camshaft design, but they aren’t the be-all, end-all of the cylinder head. It’s more about maintaining critical airspeeds through the port. You don’t race the flowbench, it’s about the whole combination,” he explains.

CFE required the cylinder heads to develop the intake manifold. Speaking of the intake manifold, the CFE sheetmetal tunnel-ram unit is designed to work specifically with this cylinder head package.

(Left) The intake manifold developed by CFE Racing has injector ports close to the cylinder head; more importantly, it has been developed for use with these particular heads on this particular engine, and should help the racer run at the top of his game. (Right) Foxwell says that the amount of time required to mock up components and ensure parts and pieces line up properly is a large part of the tedious process of building an engine of this caliber.

Mechanical fuel injection uses a pair of five-inch-bore Enderle throttle bodies to maximize airflow into the manifold. The fuel system was personally handled by Sid Waterman of Waterman Racing fame.

“It’s a bit unusual to use a pair of single-blade throttle bodies on this type of engine, but it’ll be wide-open and an old-school look,” Foxwell says.

There’s not a whole lot of extra room in these head-bolt holes. in fact, Foxwell had to turn down the exterior dimension on all of the nuts in order to lock everything down.

Actuating the valves are a set of T&D Machine Products 1.70:1-ratio rocker arms, pushed by a monster set of Smith Brothers 1/2-inch, .177-inch-thick straight-wall pushrods. Valvetrain stability under load is key; to this end the Straub team selected the strongest possible components to keep deflection at bay. Morel DLC-coated .936-inch keyway lifters are used, as Straub has an excellent relationship with Ed Morel and swears by his products.

Oiling is handled through the use of a Stef’s fully-segmented dry-sump oil pan and six-stage dry-sump pump setup from Aviaid.

As this is a dry-sump engine, enclosing the lifter valley to have its own scavenge section required machining the holes in the lifter valley, manufacturing new plugs, and press-fitting them into the valley's surface. Given the opportunity and racer budget, Foxwell says that he'd even enclose the camshaft if possible, to prevent excess oil from dripping onto the crankshaft and exacerbating windage.

Curiosity about why Straub Tech chose to run with the 611ci engine size when some of the competition has much larger engines led down an interesting path.

“Average horsepower wins races; Peak power numbers have their place but if the average isn’t there, the engine will not perform. The engine has to accelerate through an RPM range, and the better it can do that, the more efficient the engine’s going to be and the better your performance is going to be,” says Foxwell.

During the camshaft development process, Straub has Foxwell flow the cylinder head at particular critical points in order to come up with the best possible lobe profile. It’s not all about peak numbers.

This particular engine has been developed to run in the 6,500-9,500 rpm range to give the racer the broadest usable powerband and the widest tuning window. Peak power will be around 8,500 rpm.

Half-inch pushrods (as thick as small-block Ford head studs) and robust valvetrain parts throughout help to control unwanted valve events. Any unwanted motion is wasted motion and will rob power.

“From the induction to the oil pan, every part has to work together with the other parts. No one part works on its own—they all have to work together.”

In other words, not only does the engine combination have to be efficient at making horsepower, but the rest of the truck has to be designed to take advantage of the engine’s capabilities; from the gear ratios in the transmission to the gear ratios in the axles, each piece must be optimized for the engine to perform to its full capabilities.

The assembled engine, complete with monster Enderle throttle bodies on top. This is one nasty big-block Ford!