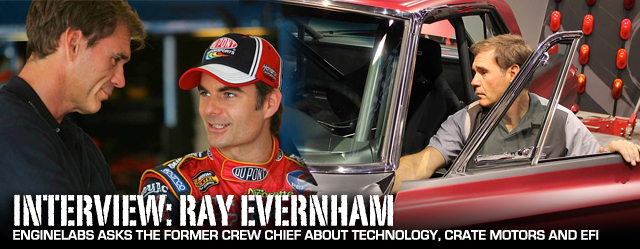

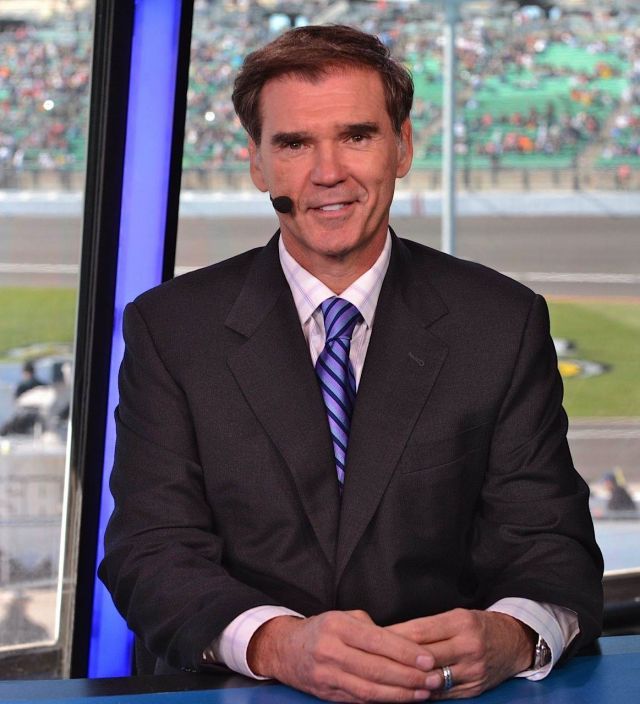

Ray Evernham is a longtime crew chief, winning three NASCAR championships with Jeff Gordon and later heading up Dodge’s return to NASCAR in 2001. He now works as an ESPN race commentator, runs a variety of auto racing marketing enterprises and just branched out into custom car design. EngineLabs editor Mike Magda caught up with Evernham at the SEMA Show in the Ingersoll-Rand booth.

EngineLabs: Given increase use of CFD, FEA and other computer simulation programs in engine development, has engine building lost some of the romance and the character that first attracted us to an engine shop?

Evernham: I really don’t think it has. There are some restrictive rules on the NASCAR engine, but those tools help you find the power. I think it’s actually made engine building a little bit more interesting because of the use of those tools. You can sit at the computer and look and learn, where we used to have to grind and dyno, or grind and flow. Now those guys are doing it with the CFD and doing it with the simulation, it’s really pretty amazing. So, in my opinion, those tools have made it a little bit more interesting.

EngineLabs: But as far as losing the romance of being in the garage all night and …?

Evernham unveiled his first custom car at SEMA, a 1964 Plymouth Belvedere that will be auctioned off at Barrett-Jackson.

Evernham: Oh, it wasn’t romance for me (laughing). I would have liked to have had a few nights off. You know, simulation — it’s here. And as an ex-crew chief, the track simulation probably has taken a little bit of that romance out for me because I used to like to tune the car at the racetrack. But as an engine builder, I think that you can get so much more done. Just look at the gains. It’s incredible what some of these normally aspirated engines are making, or even turbocharged four cylinders. And I think that is directly because of CFD and engine simulation.

EngineLabs: Then, where are the new frontiers of engine building?

We proved you could build a motor for seven or eight thousand dollars.

— Ray Evernham

Evernham: I really think it’s going to be in materials. As they develop better materials, there’s going to be a continued push towards more green energy. I don’t think that the fossil fuels are going to totally go away, but I think that there’ll probably be development in either making the gasoline engines more efficient, or finding alternative-fuel sources. I think that the development of the engine is just going to be about getting lighter; it’s going to be about getting more efficient; it’s going to be about turning more rpm to be more efficient – and that will make the parts and pieces durable. I think that you’re going to be looking at a lot of engine coatings and lubricants — all those things that help push the engine horsepower and durability forward.

The Belvedere incorporates NASCAR technology, including a former R5P7 Dodge race engine fitted with EFI.

EngineLabs: Are NASCAR engine builders actually making horsepower (under restrictive rules), or are they just finding lost horsepower?

Ray Evernham Bio

Ray Evernham started as a modified driver, then moved to IROC series where he worked as a chassis specialist. Following a brief stint with driver Alan Kulwicki, Evernham teamed up with Jeff Gordon at Hendrick Motorsports. Gordon and Evernham won 47 races and three NASCAR championships before Evernham started his own team and helped Dodge re-enter Cup racing. Evernham sold the team in 2007 and now works as an ESPN analyst.

Evernham: Well, I think it’s the same thing. You know, a lot of horsepower is lost in friction. So I think the guys are doing a good job taking the friction out. I think they’re lightening the parts up, and the new electronic fuel injection has helped them find some horsepower. But when you look at that motor, 358 cubic inches, normally aspirated, and they’re making over 900 horsepower, and turning over 9500 RPM — a push-rod driven, rocker-arm engine, and they live 600 or 700 miles all weekend. It’s pretty incredible what those guys are doing.

EngineLabs: Can you pinpoint one or two innovations that have really stood out in your mind, in terms of NASCAR engine development?

Evernham: I would say the biggest thing that’s changed engines – we’ve already talked about the software — it’s just the capability of the CNC engine equipment, and to be able to spit the stuff out and then duplicate it. And again, I think that’s really changed what you can do with raw materials. You know, you design it pretty much on the tube, and now you got a CNC machine that spits it out if you got to make a change. I think it’s really the CNC equipment and tools that have made the biggest difference.

EngineLabs: What about consistency, making sure that every cylinder works the same as the one next to it. And consistency in cylinder-head ports and designs?

Evernham: I think that’s important. The pressure stuff started several years ago, but it’s really important how the engine flows. So if they’re off, if one engine has got a cylinder pressure problem — and I don’t know what their limits are nowadays — you’re probably looking at a broken part or a motor that just doesn’t run as good.

EngineLabs: You mentioned 900 horsepower?

Evernham: Yeah, absolutely. These guys are making more horsepower with rpm. They’ve done so much development on the valve train, which was the weakest link in our engine — it still may be the weakest link. When I started those engines were 7800 to 8200 rpm. They’re 10,000 rpm now…all day long.

EngineLabs: Did valvetrain development come from the new blocks, being able to work on the geometry?

Evernham: That, and the development of materials, coatings and valve springs. You know, they just kept getting lighter and more in line. And you got to remember, that’s still a flat-tappet cam.

EngineLabs: Do you have any conclusions on how EFI performed this year?

Evernham: A pretty seamless transition, I think. There was some trouble in the beginning of the year with the electronics. But I will tell you, for something that’s been on a carburetor for over 50 years and then to switch over to electronic fuel injection, it was really seamless. I think NASCAR did a good job of calling that one.

EngineLabs: How do you view the growing trend towards crate and sealed engines in Sportsman classes?

Evernham You know, I don’t think it can be any other way, because in local racing the engine costs have just gotten too expensive. So, they’ve got to control it. The biggest thing that they still have to control with a crate engine or engine restrictions is the rules. If they keep it really restricted, and they enforce the rules, it’ll be worth it. I’m involved in a series with these sprint cars called Race Saver, and it’s a very limited engine deal. This is a growing series, because people can’t afford to race wide-open sprint cars anymore. We saw this Race Saver deal and I really believed in it. We proved you could build a motor for seven or eight thousand dollars, and there’re sprint cars for sale all over. For 15 or 16 thousand dollars, you’ve got a complete sprint car to go race. You use a 305 block, and they’re very specific about the rules. It’s a spec head that you have to buy from them. So you could put giant injectors or all kinds of stuff on it, and it’s not going to run. French Grimes came up with this series and wrote the rules — he’s a genius with engines.

Evernham as a team owner with Dodge. (Photos: Chrysler Images and Joe Wilssens)

Evernham You could build it, I could build it, you can have an engine builder build it. But in the end, there’s only so much you’re going to get out of that engine. They’ve put a weight limit on the cars, they have a tire limit, and it’s just a good fun series. And it’s not spec racing, because you can still adjust; you can do whatever. It’s like it used to be. Take the motors and the tires, which are the two most expensive pieces, out of short-track racing. If you’re a good mechanic you can build a car. If somebody else can’t, they can go buy a car, but they can’t out-money you.